Why Does Stainless Steel Perforated Sheet Rust?

Source:www.cn-psp.cnAuthor:河北森驰公司 Last updated:2025-03-04 10:37:12 Browse:

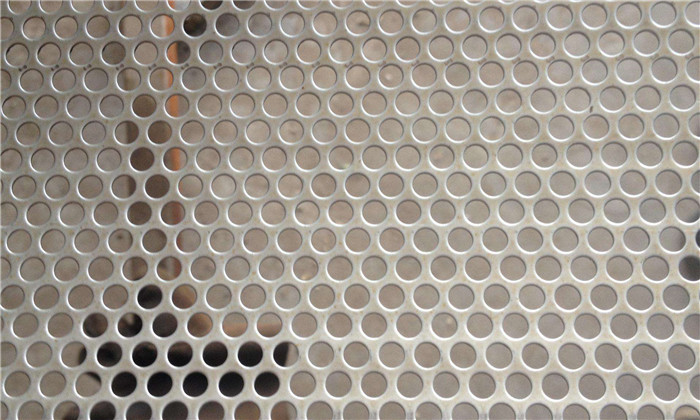

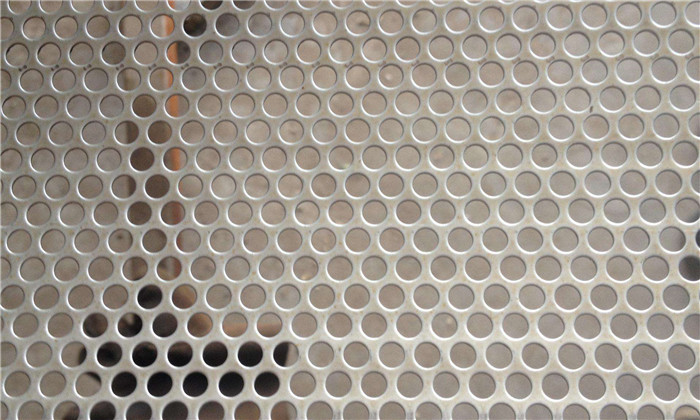

Stainless steel perforated sheet is a type of mesh material made from high-quality stainless steel plates, processed through precision CNC punching machines. It boasts excellent corrosion resistance, alkali and acid resistance, and high-temperature tolerance, making it superior to perforated sheets made from other materials. However, stainless steel perforated sheets are not immune to rusting. Under certain conditions, they can experience rust and corrosion. This article will explain in detail why stainless steel perforated sheets rust and provide some preventive measures.

Stainless steel Perforated sheet

Corrosion Resistance of Stainless Steel Perforated Sheets

The corrosion resistance of stainless steel perforated sheets comes from the thin, dense, and stable chromium oxide film (protective film) that forms on their surface. This film effectively prevents oxygen atoms from penetrating further and reacting with the metal, thereby preventing corrosion. However, this protective film is not invulnerable. When damaged, oxidation will occur again, leading to rust.

The corrosion resistance of stainless steel perforated sheets depends on several factors:

Chemical composition of the steel: Different grades of stainless steel have varying levels of corrosion resistance.

Processing and usage conditions: Factors such as temperature, humidity, and the presence of chemicals in the environment can all impact corrosion resistance.

Nature of the environmental medium: For example, exposure to salt, acid, or alkali can accelerate corrosion.

For instance, a 304 stainless steel perforated sheet performs excellently in dry, clean air, but if it is placed in coastal areas with high salt content, it may rust quickly. On the other hand, a 316 stainless steel perforated sheet has better resistance in such environments.

Common Causes of Rusting in Stainless Steel Perforated Sheets

Although stainless steel has excellent corrosion resistance, its protective film can be damaged under certain conditions, leading to rust. The following are some common causes of rusting in stainless steel perforated sheets:

Electrochemical Corrosion

When stainless steel perforated sheets accumulate dust or metal particles from other metals, these particles can form micro-cells with the stainless steel surface in a humid environment. This leads to electrochemical reactions that break down the protective film. This is often observed after home renovations, when metal debris in pipes settles on sinks and causes "floating rust."

Organic Acid Corrosion

If organic substances such as food residues (e.g., juice from fruits or vegetables, soup, etc.) accumulate on the surface of the perforated sheet, they can react with water and oxygen to form organic acids. Over time, these acids can corrode the metal surface.

Acidic or Alkaline Corrosion

If the perforated sheet surface is exposed to acidic, alkaline, or saline substances (such as splashes of lime or alkali water during construction), it can lead to local corrosion, breaking down the protective film. This is commonly seen when workers fail to clean up water from sinks after use during renovation, allowing acid or alkali to corrode the surface.

Chemical Corrosion

In areas with polluted air, such as regions with high concentrations of sulfur compounds, carbon oxides, or nitrogen oxides, condensation can form acidic liquids (such as sulfuric acid, nitric acid, or acetic acid). These acids can leave corrosion marks on the stainless steel surface.

How to Prevent Rust on Stainless Steel Perforated Sheets

To ensure the long-term durability and appearance of stainless steel perforated sheets, the following measures are recommended:

Regular Cleaning

Periodically clean and wipe down the surface of the stainless steel perforated sheet to remove dust, grease, and other substances that could lead to corrosion. Increased cleaning frequency is recommended in humid or chemically aggressive environments.

Choose Quality Products

Some stainless steel perforated sheets on the market may be made from materials that do not meet national standards, which can lead to rusting. Consumers should choose products from reputable manufacturers that meet quality standards to ensure the material’s durability and performance.

Avoid Contact with Corrosive Substances

During installation and use, avoid exposing stainless steel perforated sheets to strong acids, alkalis, or saline substances. For example, during renovations, prevent lime or alkali water from splashing onto the surface of the sheet.

Avoid Long-Term Exposure to Harsh Environments

If stainless steel perforated sheets are to be exposed to highly polluted environments, protective measures such as protective films or coatings can help reduce the impact of external environmental factors.