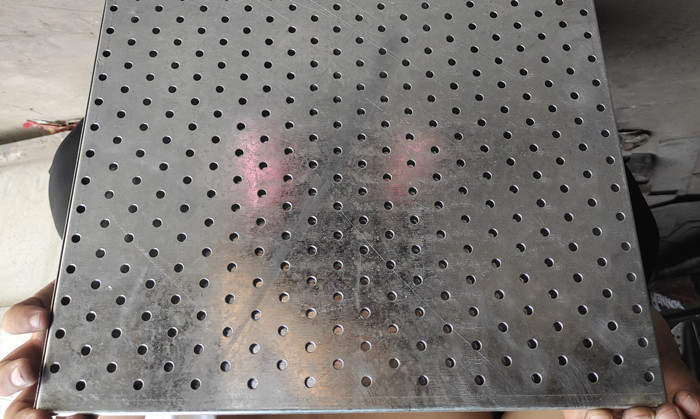

As a professional manufacturer of customized perforated drying trays from China, we are dedicated to providing high-quality drying tray solutions for global customers. By using high-quality perforated plate materials, our perforated drying trays can be customized based on customer requirements, offering more flexible options. Whether you need different sizes, hole shapes, thicknesses, or materials, we can provide tailor-made products to ensure your production process is more efficient and precise. Our drying trays are widely used in food processing, chemicals, pharmaceuticals, machinery, and other industries, meeting various drying needs.

Perforated Drying Tray Specifications & Customization

The perforated drying trays we offer are highly customizable, ensuring they fit perfectly with various drying equipment and operational environments. Below are some common specifications of our perforated drying trays, and you can choose or contact us for further customization:

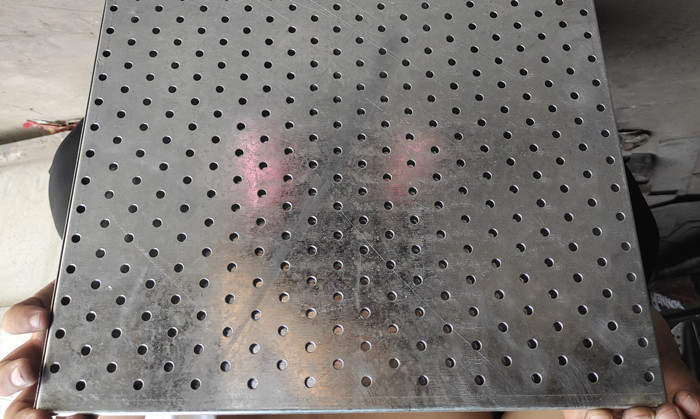

Material Options: Based on your drying needs, we offer various materials such as iron plate, aluminum plate, stainless steel, etc. Different materials offer different temperature and corrosion resistance, and customers can choose the most suitable material based on their needs.

Thickness Customization: The thickness of the perforated drying trays can be customized based on your requirements, typically ranging from 0.5mm to 3mm. Different thicknesses are suitable for different load and temperature conditions.

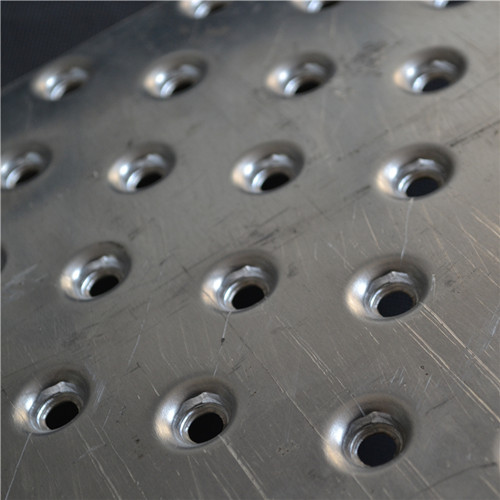

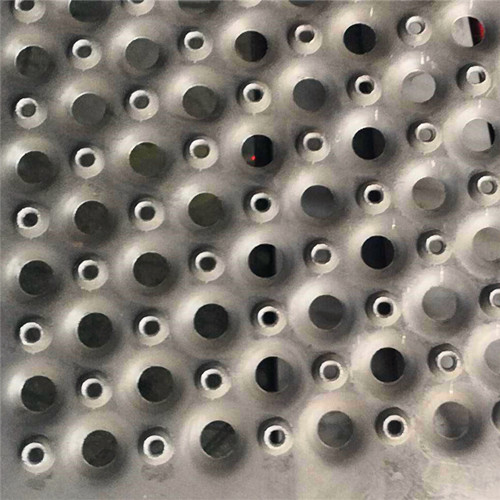

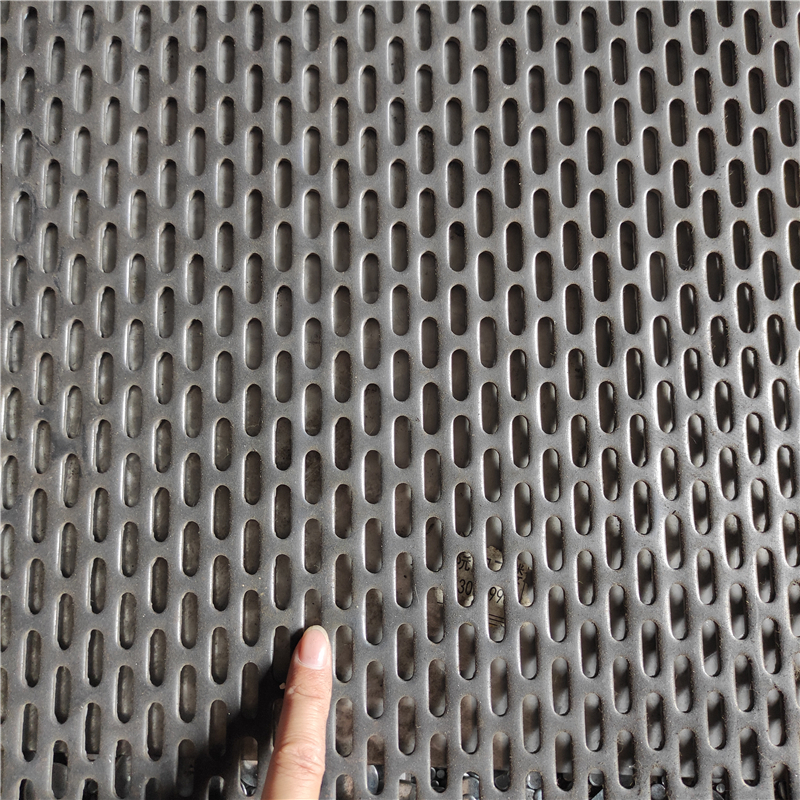

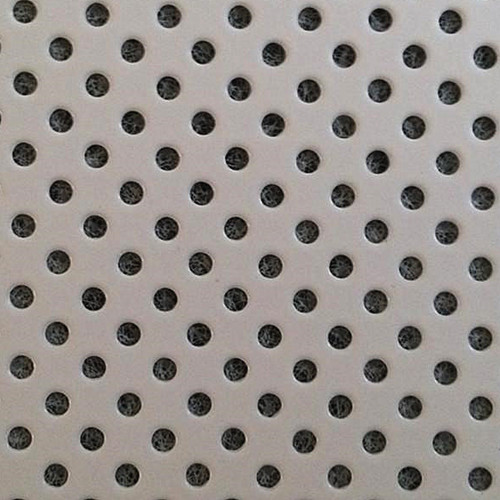

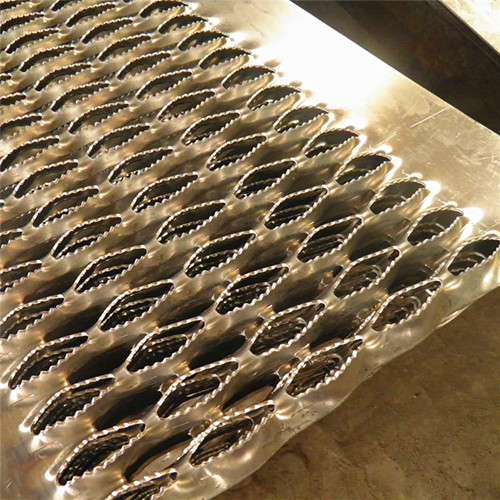

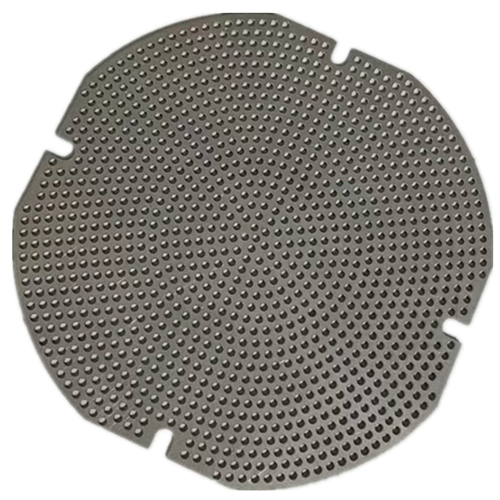

Hole Design: We offer various standard hole shapes, including round holes, oval holes, square holes, triangle holes, five-pointed star holes, hexagonal holes, eight-figure holes, cross holes, Z-shaped holes, H-shaped holes, diamond holes, etc. Different hole designs can meet different airflow and heat distribution requirements, improving drying efficiency.

Aperture Customization: We can offer aperture sizes ranging from 1mm to 30mm based on the characteristics of the drying material, helping customers achieve optimal airflow permeability, ensuring uniform heat distribution and high drying efficiency.

Hole Spacing & Arrangement: In addition to aperture size, hole spacing and arrangement can also be customized according to customer requirements, adapting to different drying processes and equipment configurations.

Features of Perforated Drying Trays

1.High-Quality Materials: We use high-strength, high-temperature-resistant perforated plate materials to ensure durability and load-bearing capacity, maintaining excellent performance and stability even in high-temperature environments.

2.Precise Manufacturing Process: Each perforated drying tray is rigorously processed and inspected to ensure accurate hole shapes and consistent dimensions, meeting high customer standards.

3.Highly Customizable: We provide comprehensive customization services based on different customer needs, allowing for personalization in weight, size, material, etc., avoiding the need for secondary processing.

4.Corrosion & High-Temperature Resistance: Our stainless steel perforated drying trays offer excellent corrosion resistance and high-temperature performance, making them suitable for harsh environments and extending product service life.

5.Efficient Drying Performance: Through well-designed hole shapes and apertures, our drying trays ensure uniform heat distribution, improving drying efficiency, reducing drying time, and saving energy.

6.Eco-Friendly & Energy-Saving: Our products use eco-friendly materials, are lightweight, and recyclable, meeting global environmental standards and helping customers reduce operational costs and improve production efficiency.

7.Aesthetic & Easy to Clean: We focus on product appearance, with smooth surfaces on our perforated drying trays that are easy to clean, reducing maintenance costs.

Wide Industry Applications

Perforated drying trays, as a versatile and high-performance product, are widely used in multiple industries, particularly in the following areas:

Food Industry: Suitable for dehydration and drying of various foods, such as fruits, vegetables, meats, seafood, etc., helping to improve drying quality while preserving nutrition and taste.

Chemical Industry: During chemical material drying, perforated drying trays provide uniform airflow distribution, ensuring even heating of materials and accelerating drying speed.

Pharmaceutical Industry: In the drying of pharmaceuticals and herbs, our drying trays provide precise temperature control to prevent high temperatures from damaging materials and ensure product quality.

Machinery & Manufacturing: In the drying of mechanical parts, perforated drying trays effectively accelerate the process and improve production efficiency.

Logistics Industry: In logistics and warehousing, drying trays are used for drying packaging materials or other items, ensuring goods remain dry and clean during transport.

Perforated Drying Tray Pricing & Quotes

The price of perforated drying trays depends on various factors, including material type, size, thickness, and hole design. Different specifications and customization requirements will directly affect the final price. To get an accurate quote, please contact us by email with your specific needs (e.g., tray size, material, hole design, etc.), and our professional customer service team will provide a detailed quote and more product information.

Contact Us

If you are interested in our perforated drying trays or would like to learn more about customization options and technical support, please contact us using the following details:

Email: 342096438@qq.com