How to install the perforated metal

Source:www.cn-psp.cnAuthor:河北森驰公司 Last updated:2024-10-10 12:54:33 Browse:

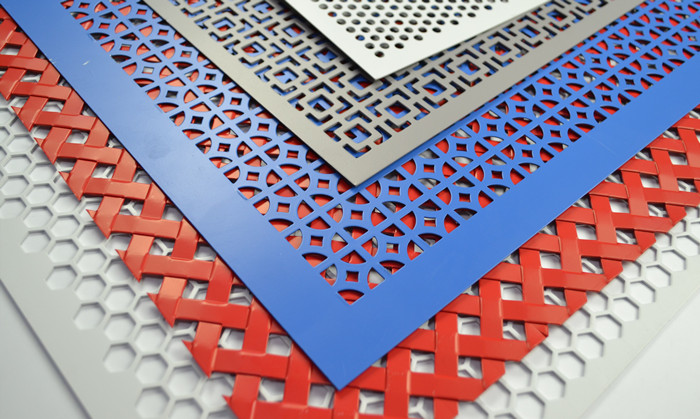

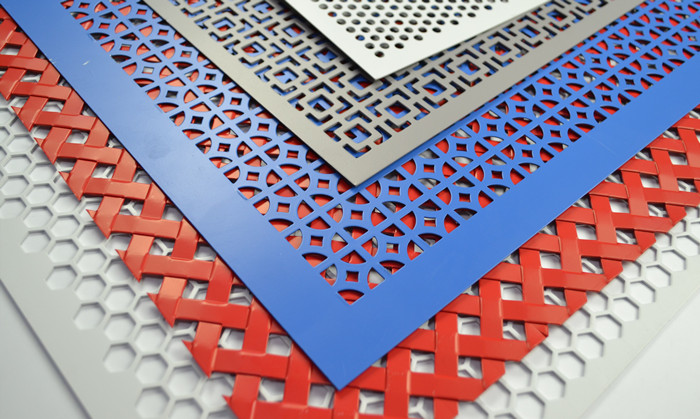

Perforated metal is a type of net product produced by continuous punching on metal sheet materials according to customized molds on precision numerical control punching machines. It is commonly used in the fields of architectural decoration, screening and filtration, and ventilation and noise reduction. Many users do not know how to install perforated metal products. Below, Anping Xinsen Punched Metal Mesh Factory will explain in detail how to install perforated metal.

The installation of perforated metal products includes welding installation, screw fixing, bending and snap-in etc. Among them, the above installation methods can be selected for iron perforated metal and stainless steel perforated metal products.

Aluminum perforated metal is usually recommended to be installed by screw fixing or bending and snap-in.

Welding installation of perforated metal is usually done on the back of the product, which will not affect its appearance. It is recommended to have a welding point every 20cm. For perforated metal products with thicker plate materials, the welding point spacing should be increased.

Screw fixing installation of perforated metal is usually produced with screw holes at the same time during production. After receiving the product, users can directly install it. Screw fixing installation of perforated metal can also be installed with yin tail thread (self-tapping screw), without the need to pre-drill screw holes during production.

The snap-in installation method is very simple. Users can directly install the perforated metal product after receiving it. The snap-in installation of perforated metal not only makes installation convenient, but also increases the strength of the product.

perforated metal