2025-05-13

2025-03-04

2025-05-21

2025-06-07

2025-04-11

2025-06-14

2025-05-19

2025-05-19

2025-06-14

2025-01-10

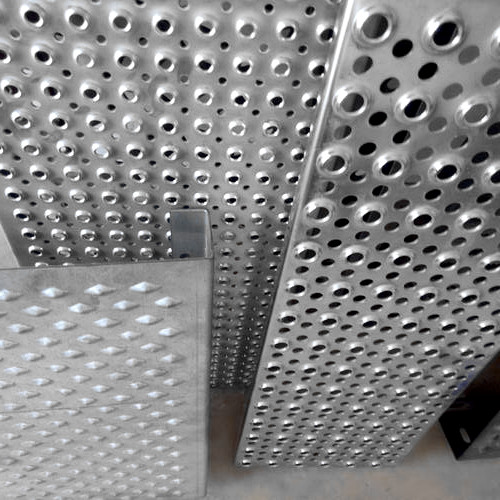

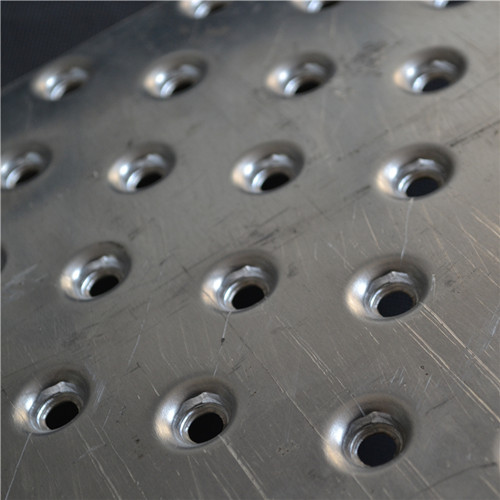

Perforated Anti-skid Plate

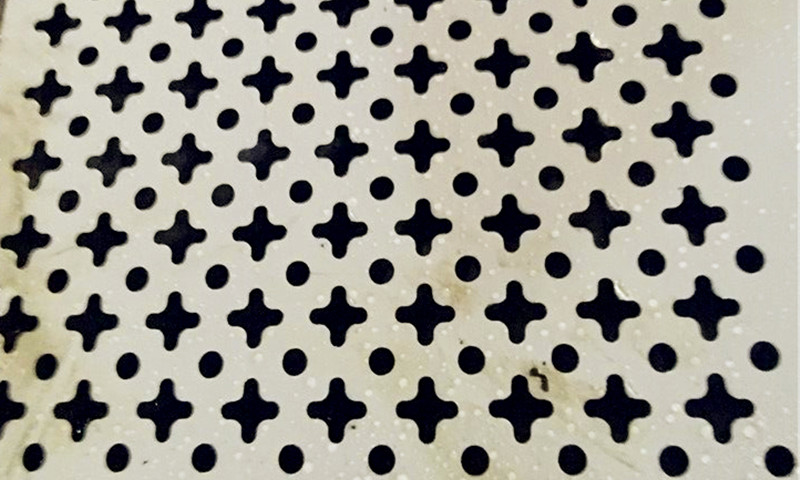

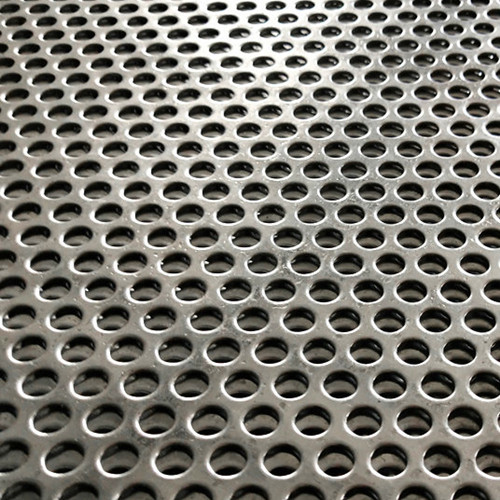

Stainless Steel Sieve Sheet

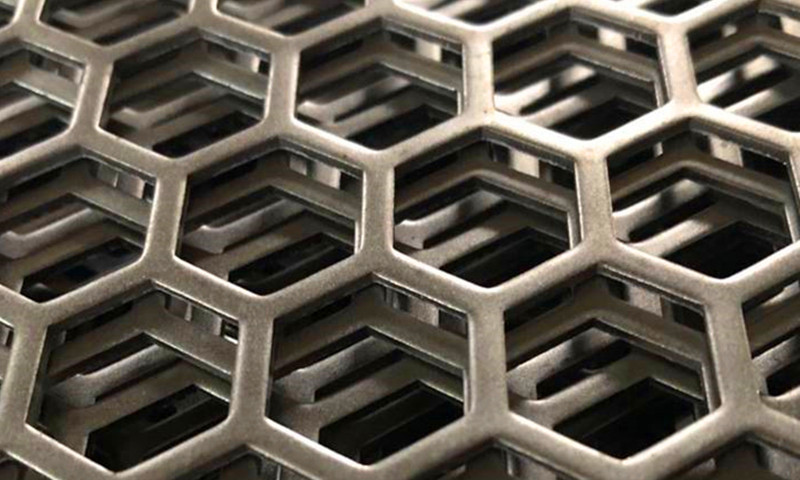

Grip Strut Safety Grating

Stair Grip Strut Safety Grating

Circular Hole Sieve Sheet

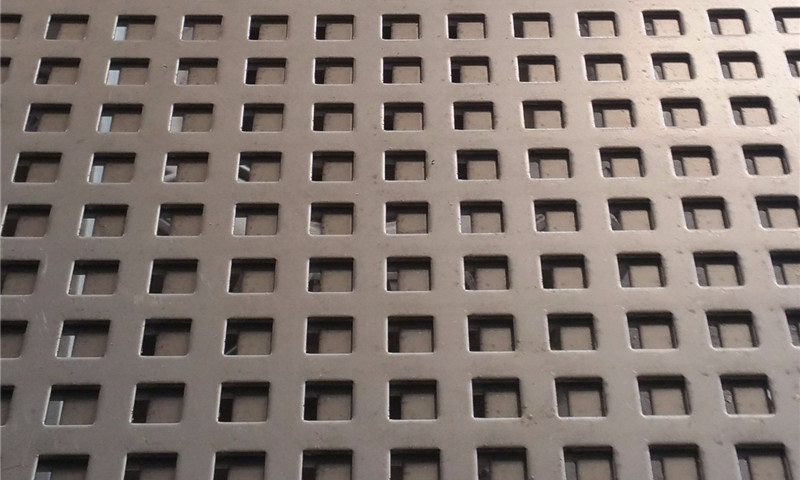

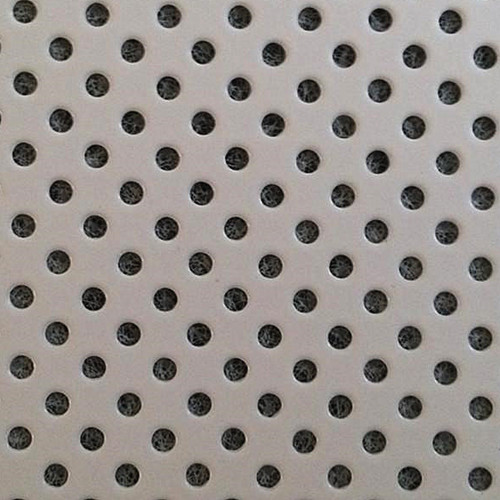

Carbon Steel Punched Metal Plate

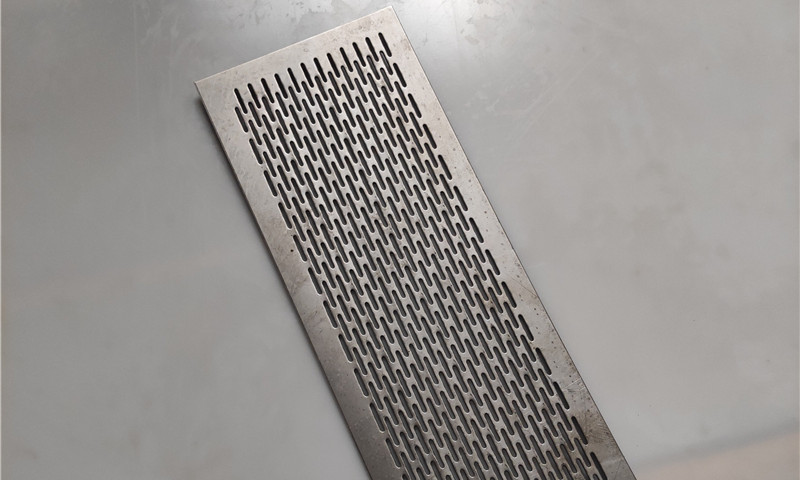

Walkway Grip Strut Safety Grating

Carbon Steel Grip Strut Safety Grating

Slotted Hole Sieve Sheet

Grain Sorting Screen Plate

High Manganese Steel Sieve Sheet

Carbon Steel Perforated Sheet

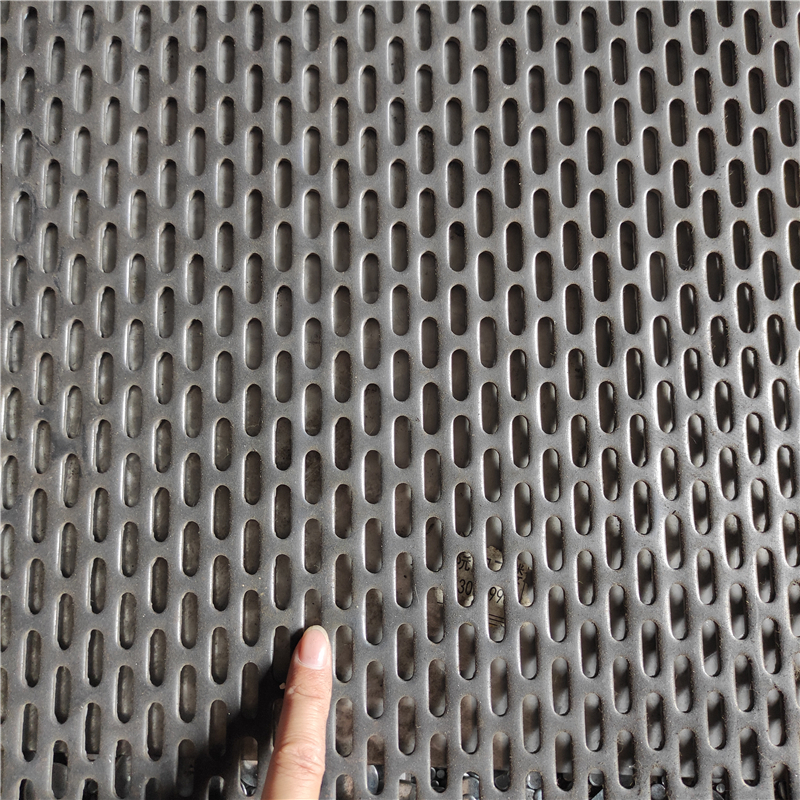

Obround Hole Sieve Sheet

Galvanized Screening Plate

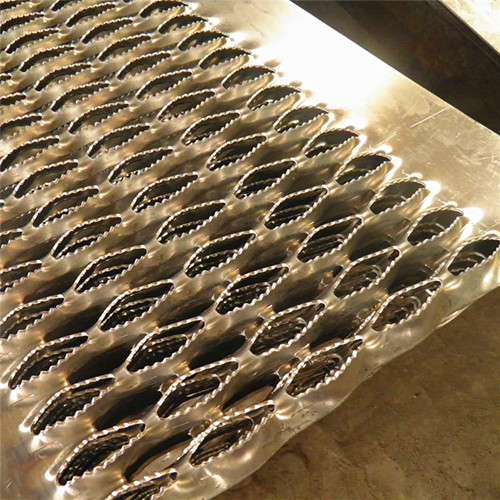

Serrated Grip Strut Safety Grating