Detailed Production Process of Perforated Metal Sheets

Source:www.cn-psp.cnAuthor:河北森驰公司 Last updated:2025-04-11 09:59:46 Browse:

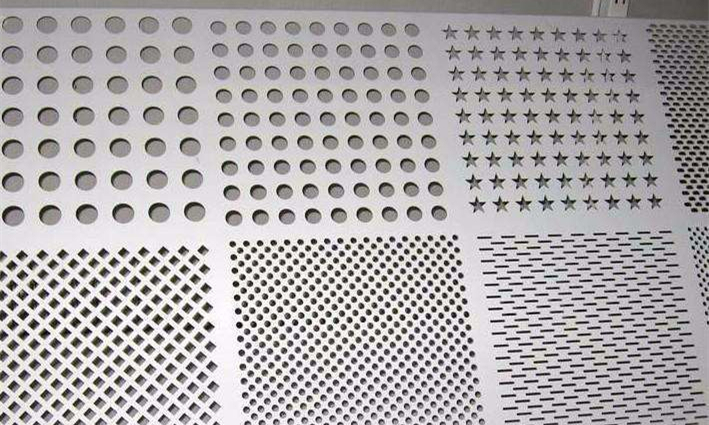

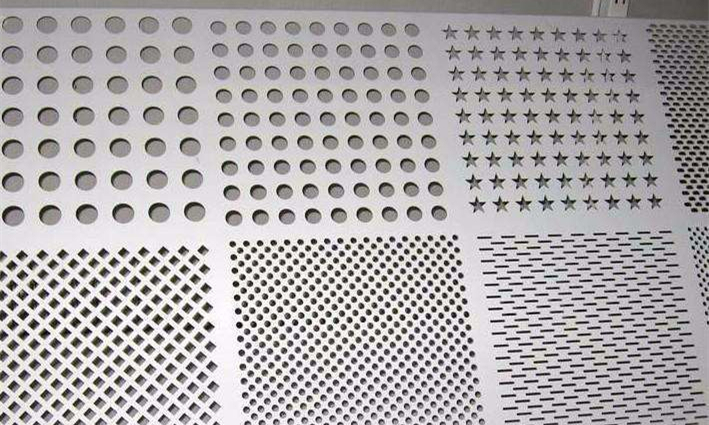

Perforated metal sheets are widely used in construction, industrial filtration, and decorative applications due to their smooth, uniform surfaces, precisely aligned holes, and long-lasting durability. So, how are perforated metal sheets manufactured?

1. Coil Cutting:

The raw materials for perforated metal sheets can be made from various metals such as stainless steel, cold-rolled steel, hot-rolled steel, galvanized steel, or aluminum. These sheets are first cut to the required specifications based on customer requirements to ensure the dimensions meet production standards.

2. Perforating:

After cutting, the material is placed on a CNC punching machine for continuous perforation according to the specified hole diameter, pitch, and pattern. This step ensures each perforated metal sheet features accurate and evenly distributed holes that match the customer’s design.

Perforated metal sheets

3. Leveling:

During the punching process, stainless steel or other metal sheets may deform slightly. To guarantee the flatness of the perforated metal sheet, a multi-roll leveling machine is used to flatten the surface, ensuring a smoother and more even finish.

4. Cutting to Size:

Standard widths for stainless steel and other metal sheets are usually 1 meter, 1.2 meters, or 1.5 meters. If the desired dimensions differ from these standard widths, the sheets are cut accordingly to meet the specific size requirements of the customer.

5. Secondary Processing:

After cutting, additional processing may be carried out based on specific customer needs. These processes can include bending, rolling, electrolytic polishing, or surface cleaning to remove stains and enhance surface quality.

6. Packaging:

Once cleaned, the perforated metal sheets are packaged according to storage and transportation standards, ensuring they remain clean and well-protected during transit.

The entire production process ensures both the quality and appearance of the perforated metal sheets while also enhancing their versatility. This enables them to meet the high-precision and durability demands of various industries.