What Information Do You Need to Provide When Customizing Perforated Metal Sheets?

Source:www.cn-psp.cnAuthor:河北森驰公司 Last updated:2025-03-04 13:16:02 Browse:

When customizing perforated metal sheets, in order to ensure that the final product fully meets your needs and achieves the expected results, you need to provide a series of detailed information to the manufacturer. This information not only helps the manufacturer better understand your needs but also improves production efficiency and product quality. Below is the key information required when customizing perforated metal sheets:

1.Basic Specification Parameters

Material Type: Clearly specify the required metal material, such as stainless steel, aluminum, copper, or other alloys.

Thickness: Specify the thickness of the sheet, usually measured in millimeters or inches.

Dimensions: Provide the required length and width of the sheet, as well as whether a specific shape is needed (such as circular, rectangular, etc.).

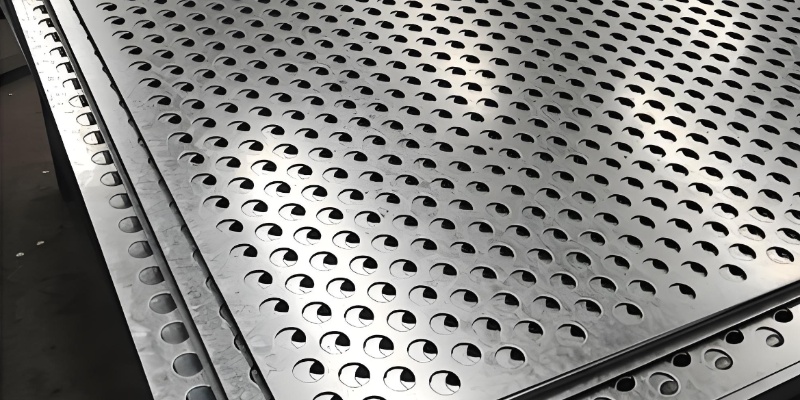

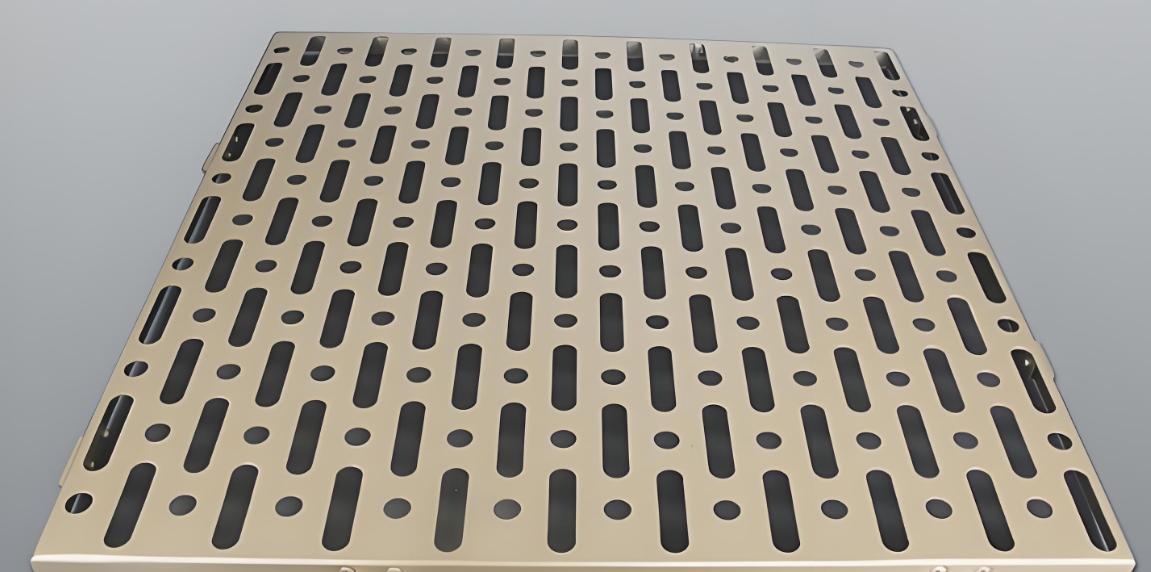

2. Hole Design

Hole Diameter Size: Determine the diameter or side length of the holes, which will directly affect the functionality and appearance of the product.

Hole Type: Choose the desired hole type, such as round, square, oval, hexagonal, or other special shapes.

Hole Spacing: Define the distance between holes (center-to-center distance), which determines the perforation density and light/air permeability.

3. Surface Treatment

Surface Treatment Process: Select the appropriate surface treatment method based on usage, such as polishing, brushing, sandblasting, electroplating, etc.

Color Requirements: If a specific color or coating is needed, please specify in advance.

4. Functional Requirements

Usage: Describe the specific use of the perforated metal sheet, such as for architectural decoration, soundproof barriers, filtration equipment, or other fields.

Performance Requirements: If there are special performance requirements (such as corrosion resistance, compressive strength, fire protection level, etc.), please explain in detail.

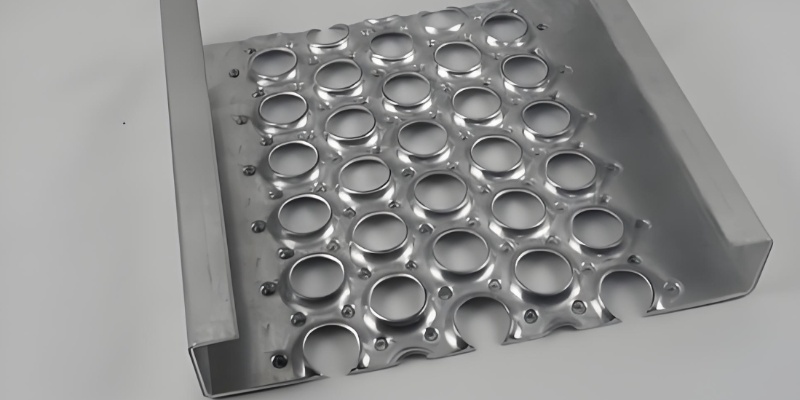

5. Processing and Installation Details

Edge Treatment: Whether edge chamfering, bending, or other special treatments are needed?

Connection Method: Provide information about how to fix or install the perforated sheet, such as bolt hole positions, welding points, etc.

6. Quantity and Delivery Time

Order Quantity: Clearly state the quantity ordered to help the manufacturer plan production reasonably.

Delivery Time: Inform us of the expected delivery date to ensure timely completion of production.

7. Other Considerations

Drawings or Samples: If there are existing design drawings or reference samples, they can be provided together to the manufacturer.

Quality Standards: If following specific industry standards or certification requirements (such as ISO, ASTM, etc.), please declare in advance.

By providing the above detailed information, you can help the manufacturer more accurately understand your needs and ensure that the produced perforated metal sheets fully meet your expectations. If you have any questions or uncertainties, feel free to contact us at any time! Our professional team will sincerely serve you and help you achieve the best solution.