We can provide customers with perforated metal sheets of custom sizes or designs

Source:www.cn-psp.cnAuthor:河北森驰公司 Last updated:2025-03-04 13:16:11 Browse:

As a leading manufacturer specializing in perforated metal sheets, we understand that each customer's needs are unique. To meet the diverse demands of the market, we not only offer standard products but also place great emphasis on customization services, ensuring that every customer can find the perfect solution tailored to their specific requirements.

1. Highly Flexible Size Customization

Our production capabilities cover a wide range of sizes, from small to large. Whether it is for architectural decoration, acoustic treatment, filtration systems, or industrial equipment, we can perform precise cutting and processing according to the specific requirements of our customers. Customers simply need to provide parameters such as length, width, thickness, and hole size, and our professional team will quickly develop a detailed production plan while ensuring minimal dimensional errors in the product.

In addition, we support non-standard size production, including irregularly shaped panels or oversized panels. Through advanced CNC machines and laser cutting technology, we can easily handle various complex geometric shapes, ensuring that every perforated metal sheet meets the high standards of our customers.

2. Personalized Design and Innovative Technology

Beyond size customization, we also offer comprehensive design support services. Customers can submit design drawings or creative concepts based on their project needs, and our design team will work closely with the customer to transform ideas into actual products. Below are some common design elements we support:

Hole Type Selection: Various hole types are available, including round, square, triangular, diamond-shaped, and more. We can also develop special shapes according to customer needs.

Hole Spacing and Arrangement: Supports regular arrangement, random distribution, or other special layouts to meet different functional or aesthetic requirements.

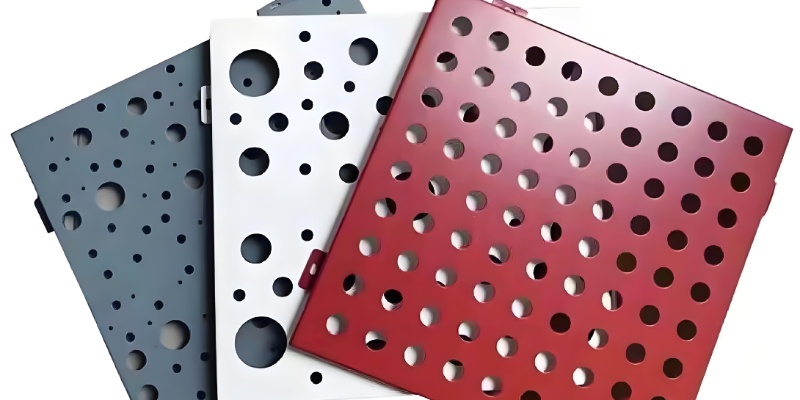

Surface Treatment: A variety of surface treatment options are provided, including spraying, galvanizing, brushing, plating, etc., giving the product stronger corrosion resistance and a more attractive appearance.

Color Customization: Based on the customer's brand color or project needs, we can achieve precise color matching, making the perforated metal sheet a highlight in the overall design.

For applications requiring higher artistic value, we can combine 3D modeling technology and engraving techniques to create unique art pieces or iconic building components.

3. Strict Quality Management System

Quality is the lifeline of an enterprise and our commitment to customers. To ensure that each product reaches the highest standard, we have implemented a comprehensive quality management system covering multiple stages, including raw material procurement, production process monitoring, and finished product inspection. All products must pass strict tests, including dimensional accuracy testing, surface flatness evaluation, tensile strength experiments, etc., ensuring stable and reliable performance.

At the same time, we closely monitor industry trends and technological advancements, continuously introducing new materials and advanced equipment to maintain our leading position in market competition. Regardless of whether you need carbon steel, stainless steel, aluminum alloy, or other special materials for your perforated metal sheets, we can provide the best solution.

4. Efficient Service Process

From the initial consultation stage to the final product delivery, we always adhere to a customer-centric service philosophy. Here is our typical service process:

1. Needs Communication: Understand the specific needs of the customer, including size, design, usage, etc.

2. Solution Design: Develop a detailed technical solution based on customer needs and provide samples for customer confirmation.

3.Production Manufacturing: Start the production line and strictly follow the design plan for processing.

4. Quality Inspection: Conduct a comprehensive inspection after completing the product to ensure there are no defects.

5. Logistics Delivery: Arrange safe and reliable transportation methods to ensure timely delivery of the product to the customer’s hands.

In addition, we offer comprehensive after-sales services, including technical support, maintenance, repairs, and secondary processing, among other value-added services, aiming to create more value for our customers.

In summary, if you are looking for a supplier that can provide custom-sized or designed perforated metal sheets, then we are undoubtedly your best choice. With excellent technical capabilities, rich practical experience, and superior service levels, we will wholeheartedly serve you and help you achieve the perfect implementation of your project. Please feel free to contact us at any time to start a pleasant cooperation journey!