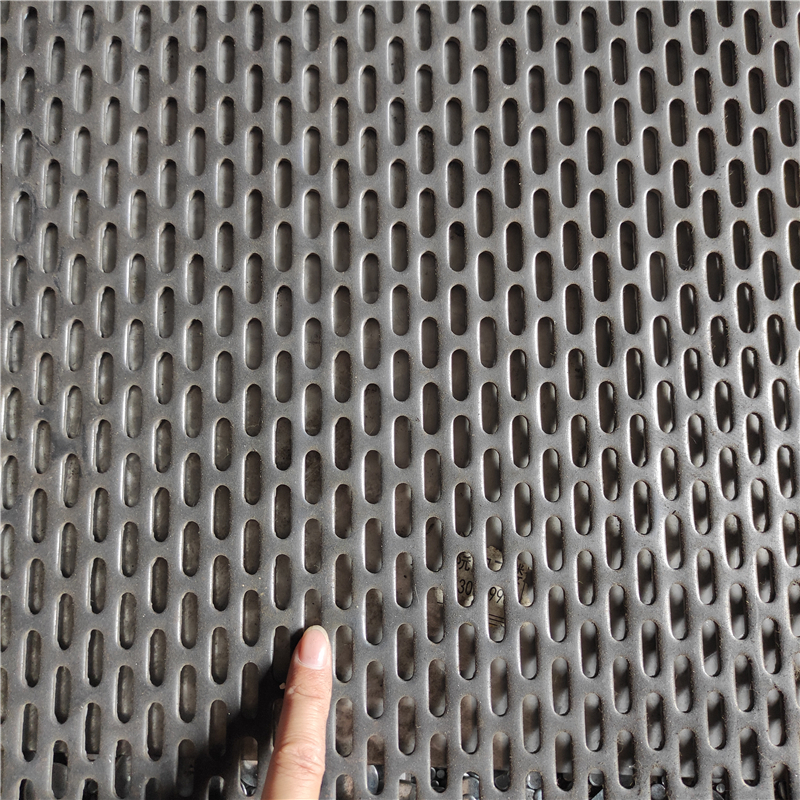

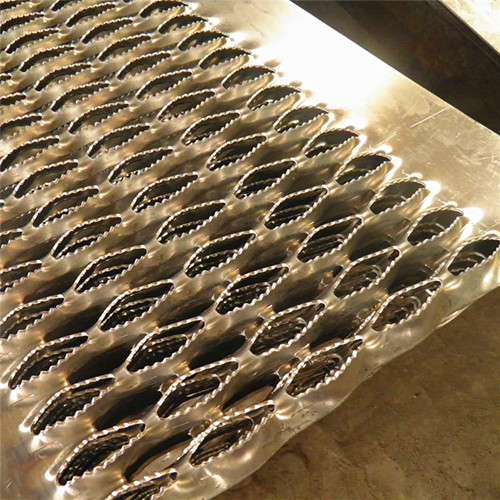

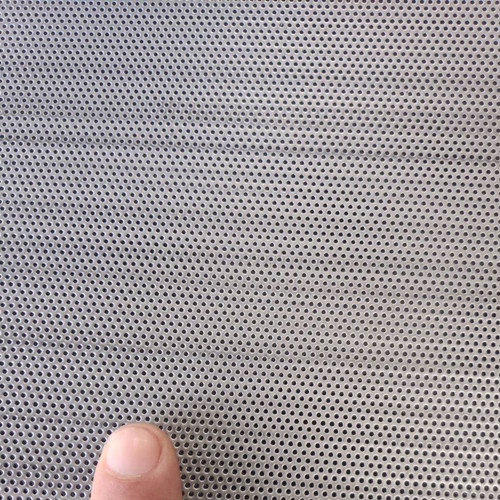

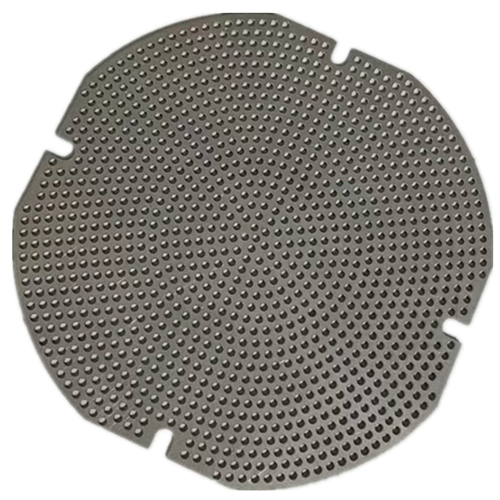

The Waist Hole Sieve Plate, also known as long waist hole perforated panels, is a type of mesh product made from high-quality metal sheets. It is processed by continuous blanking using customized dies on CNC punching machines. The products feature a flat mesh surface, uniform hole spacing, precise hole shapes, and high strength, making them highly durable and widely applicable across various industries.

Waist Hole Sieve Plate Specification

Waist Hole Sieve Plates come in various specifications and models. Users can customize the size, thickness, material, hole size, and other characteristics based on specific needs. Common specifications and customization details are as follows:

Sheet Size: The width can be customized up to 1.5 meters, and the length can be customized up to 4 meters, processed to meet customer requirements.

Sheet Thickness: Available in thicknesses ranging from 0.1mm to 20mm, catering to different industrial demands.

Material: Options include cold-rolled plate, hot-rolled plate, galvanized plate, manganese steel plate, aluminum plate, stainless steel plate, and more, depending on the application environment.

Mesh Size: Customizable mesh hole sizes ranging from 1mm to 300mm.

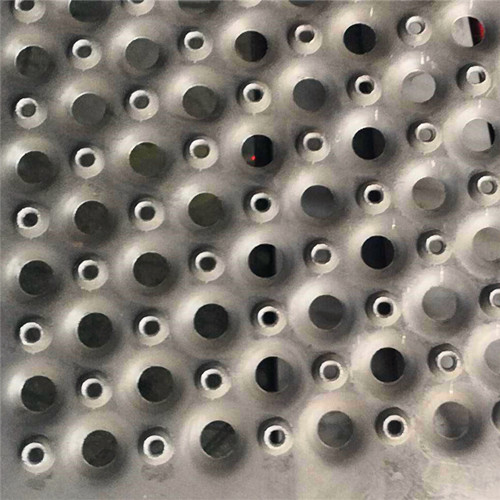

Hole Shape: The standard hole shape is elliptical, providing efficient material separation.

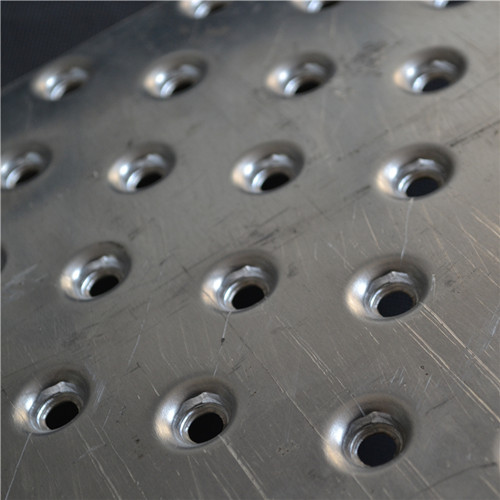

Surface Treatment: Different surface treatments are available for various materials, including spray painting, fluorocarbon spraying, electrostatic powder coating, anodizing (for aluminum), and electro-polishing (for stainless steel), ensuring corrosion resistance and aesthetic appeal.

Advantages of Waist Hole Sieve Plates

Precision Customization

We provide comprehensive customization services according to customer requirements, ensuring each waist hole sieve plate meets specific application standards. Whether for special sizes, thicknesses, hole shapes, or materials, we can precisely manufacture the right product to achieve optimal screening performance.

High-Quality Materials

We use high-quality raw materials, including stainless steel, aluminum, carbon steel, and more, to ensure the durability and performance of the sieve plates in various industrial environments.

Advanced Processing Technology

Our state-of-the-art CNC punching machines and molds ensure precise hole shapes and consistent hole sizes, eliminating the need for secondary processing. The sieve plates are ready for use immediately after production.

Diverse Surface Treatments

To enhance the durability and performance of the sieve plates, we offer a variety of surface treatments. These treatments improve the corrosion resistance, high-temperature performance, and overall aesthetics of the sieve plates, ensuring long-lasting service life in demanding environments.

Fast Delivery

In addition to fully customized services, we also offer stock supply for commonly used specifications. This allows customers to quickly obtain the required sieve plates, reducing lead times and ensuring timely delivery.

Applications of Waist Hole Sieve Plates

Waist hole sieve plates are widely used in various industries due to their unique features, including:

Mining Industry: Used for mineral screening, ensuring precise particle size classification and improving resource recovery rates.

Chemical Industry: Applied for screening and grading chemical materials, ensuring product uniformity and stability.

Metallurgical Industry: Suitable for screening tasks in high-temperature and high-pressure environments, meeting the rigorous standards of metallurgical production.

Environmental Protection: Used in waste treatment, water filtration, and other environmental protection applications to help separate harmful substances and meet environmental standards.

Waist Hole Sieve Plate Pricing

The price of waist hole sieve plates varies based on specifications, models, and customization requirements. To obtain a precise quotation, please contact us via email with the details of the specifications and models you need, and we will provide an accurate quote tailored to your requirements.

Why Choose Us?

Custom Solutions: We offer tailored waist hole sieve plate solutions based on customer requirements, ensuring optimal performance for specific industries and operating conditions.

Premium Materials: We use a range of high-quality materials, such as stainless steel, aluminum, and carbon steel, ensuring the durability and performance of the sieve plates.

Precision Manufacturing: Advanced production equipment and precision processing technology ensure accurate hole sizes and shapes, eliminating the need for secondary processing.

Professional Team: Our experienced team can provide technical support and recommendations to help customers select the best sieve plate solutions for their needs.