Product Overview

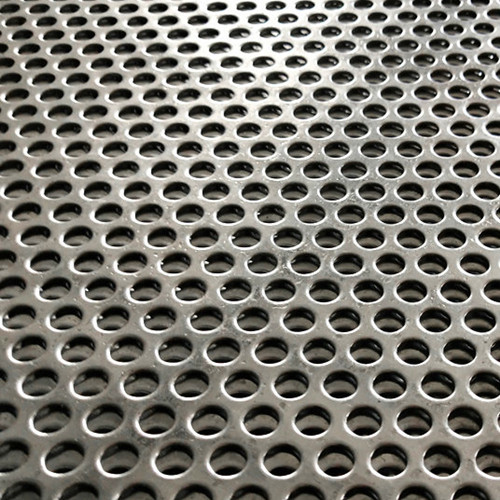

Perforated safety grating is an effective anti-slip product widely used in industrial environments. It is made from high-quality metal sheets processed with a CNC punching machine according to a custom mold. The punching process creates a unique pattern of concave and convex holes, enhancing the anti-slip properties of the grating. This product is particularly suitable for wet and greasy environments, such as water treatment plants, sewage treatment facilities, and steel structure platforms, offering enhanced safety for workers.

The perforated safety grating features evenly spaced holes and a high-strength structure, ensuring excellent anti-slip performance that meets the requirements of various work environments. We provide customized design options to ensure that each grating perfectly fits the safety protection needs of our clients.

Specifications and Customization

Our perforated safety grating comes in a variety of specifications, and customers can customize the product based on their specific needs. Whether it is the sheet size, thickness, material, hole pattern, or surface treatment, we can provide tailor-made solutions to ensure the grating meets the safety and functional requirements of your application.

Sheet Size: Standard width less than 1.5 meters, length less than 4 meters; custom sizes are available.

Sheet Thickness: Thickness ranges from 1mm to 3.5mm, with customized options available.

Material: We offer a variety of materials including cold-rolled steel, hot-rolled steel, galvanized steel, manganese steel, aluminum, and stainless steel to meet different corrosion resistance requirements.

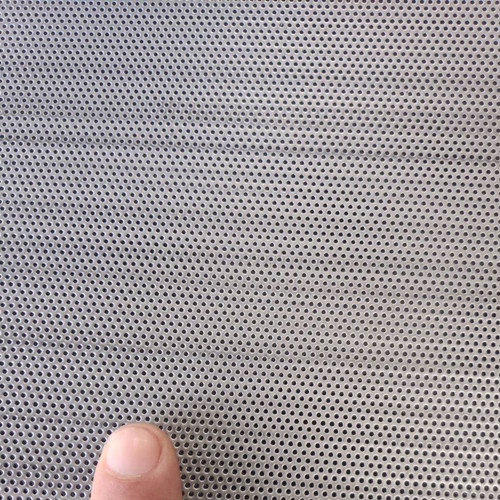

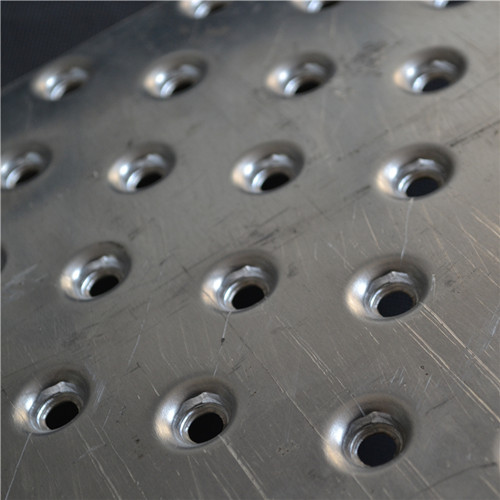

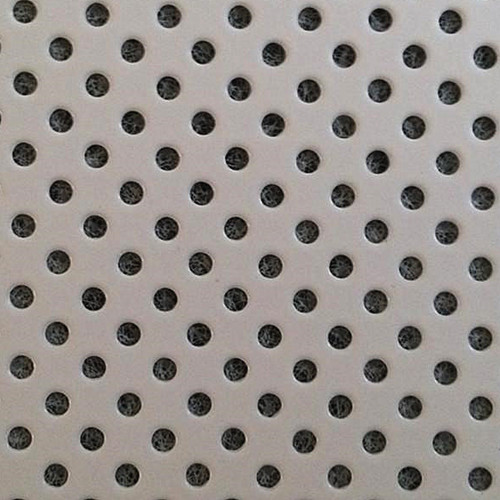

Hole Pattern: Common hole patterns include crocodile mouth and round drum types. Customers can choose the pattern according to their needs.

Surface Treatment: Available surface treatments include spray painting, fluorocarbon coating, electrostatic powder coating, anodizing, and electrolytic polishing, ensuring corrosion resistance and durability.

Product Features

Excellent Anti-Slip Performance

Perforated safety grating features a unique punching process that creates concave and convex holes, enhancing the anti-slip effect. It provides effective protection against slipping, especially in wet or oily environments, ensuring worker safety.

High Strength and Durability

The grating is made from high-strength metal materials that are resistant to corrosion and high temperatures, making it suitable for use in harsh environments. It performs excellently even in areas with high humidity or strong chemical exposure.

Customized Design

We offer flexible customization options to meet your specific needs. Whether it's the size, material, hole pattern, or surface treatment, we can create a product that perfectly suits your environment.

Corrosion and Heat Resistance

The materials and surface treatments of our perforated safety grating provide exceptional resistance to corrosion, allowing it to withstand exposure to acidic, alkaline, or damp environments, while maintaining stability in high-temperature settings.

Easy Maintenance and Cleaning

The design of the perforated safety grating simplifies cleaning and maintenance, reducing long-term operational costs and ensuring ease of use.

Eco-friendly and Sustainable

Our products comply with environmental standards, using recyclable materials and minimizing environmental impact during the manufacturing process. This helps clients achieve their sustainability goals.

Applications

Perforated safety grating is suitable for various industrial environments, especially those with wet, oily, or corrosive conditions. It offers reliable safety protection in a wide range of applications, including:

Water Treatment and Sewage Plants: Effective anti-slip protection in wet conditions, reducing the risk of slips and falls.

Steel Structure Platforms: Provides excellent anti-slip performance to ensure the safety of workers on industrial platforms.

Automated Production Lines: Prevents slipping of materials and ensures safe, stable production processes.

Robotics and Automation Equipment: Offers safety protection around equipment, reducing accident risks from worker-machine interaction.

Specialized Industrial Environments: Such as chemical plants and mines, where perforated safety grating provides continuous safety protection for employees.

Pricing and Inquiries

The price of perforated safety grating varies depending on the material, specifications, and customization options. We offer precise quotations based on your requirements. Please feel free to contact us via email with your specifications, and we will provide a detailed quotation.

Email: 342096438@qq.com

Why Choose Us?

1.Rich Experience: As a professional perforated safety grating manufacturer, we have years of experience producing high-quality products that meet international standards.

2.Global Service: We serve customers worldwide, providing customized solutions to meet the unique needs of different markets.

3.Continuous Innovation and Quality Assurance: We are committed to continuous technological innovation to offer more efficient, safer, and more eco-friendly perforated safety grating products. All our products undergo strict quality control and testing.