Key Factors Influencing Perforated Sheet Pricing

Source:www.cn-psp.cnAuthor:河北森驰公司 Last updated:2025-05-19 14:56:11 Browse:

1. Impact of Material on Pricing

When sourcing a Perforated Sheet, the base material—carbon steel, aluminum alloy, or stainless steel—directly affects both raw‑material cost and maintenance requirements:

Stainless Steel Perforated Sheet: Highest price, excellent strength and corrosion resistance; widely used in food processing or medical equipment where hygiene is critical.

Choosing the right Perforated Sheet material balances initial cost against durability and maintenance.

2. Influence of Thickness on Price

Sheet thickness determines raw‑material usage and processing difficulty:

Thin Sheet (0.2–2 mm): Low material cost and fast punching; Perforated Sheet prices stay minimal.

Medium‑thick Sheet (2–10 mm): Increased material cost and higher press requirements; moderate Perforated Sheet pricing.

Thick Sheet (10–30 mm): High material expense, often requiring heavy‑duty presses or plasma cutting; Perforated Sheet quotes peak.

Each additional millimeter of thickness drives the Perforated Sheet cost upward, especially beyond 10 mm.

3. Effect of Dimensions on Quote

Standard coil widths (1 m, 1.2 m, 1.5 m) yield better material utilization and lower waste:

Standard Dimensions: Minimized offcuts, more economical Perforated Sheet pricing.

Non‑standard Sizes: Extra cutting or splicing, more scrap, and higher Perforated Sheet quotes.

Opting for sizes close to standard coil widths reduces waste and lowers Perforated Sheet costs.

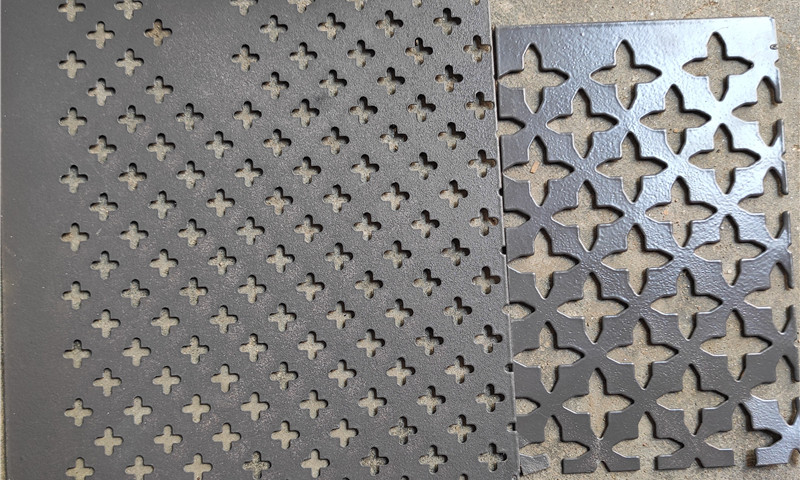

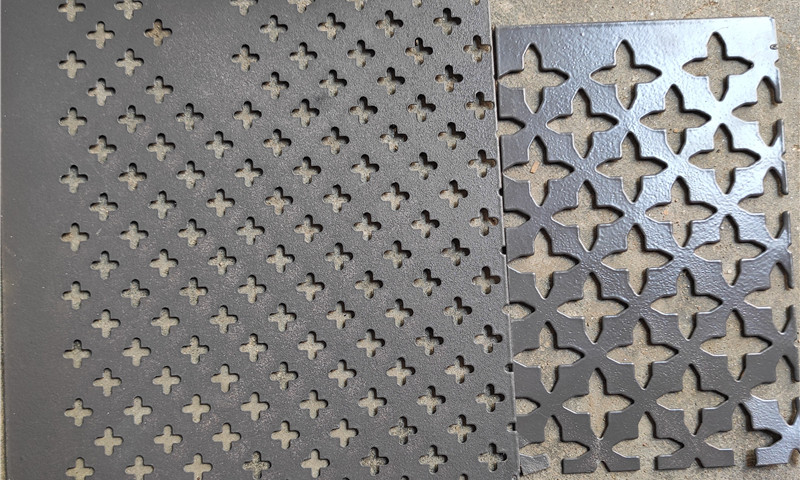

4. Role of Hole Type in Cost

Perforated Sheet hole patterns vary:

Round Holes: Most common and efficient, offering the lowest Perforated Sheet price.

Square or Slotted Holes: Require custom dies and longer processing, raising Perforated Sheet cost.

Custom Shapes (e.g., triangles, stars): Often need laser or plasma cutting, resulting in the highest Perforated Sheet quotes.

Selecting a standard hole type where possible keeps Perforated Sheet expenses down.

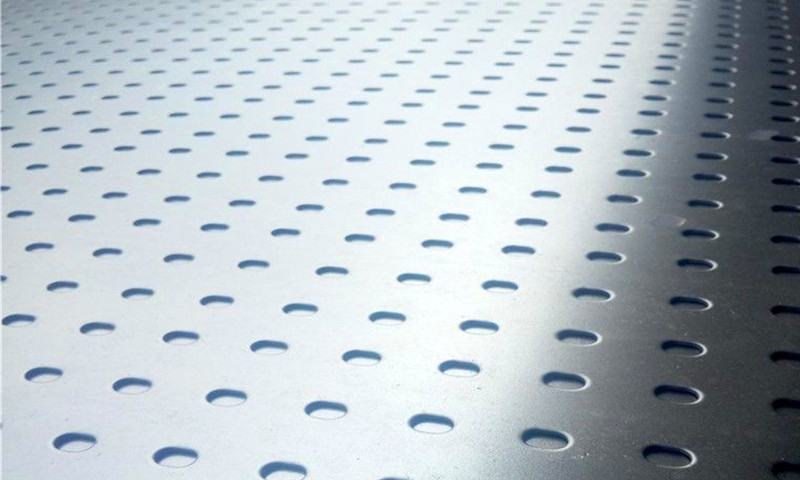

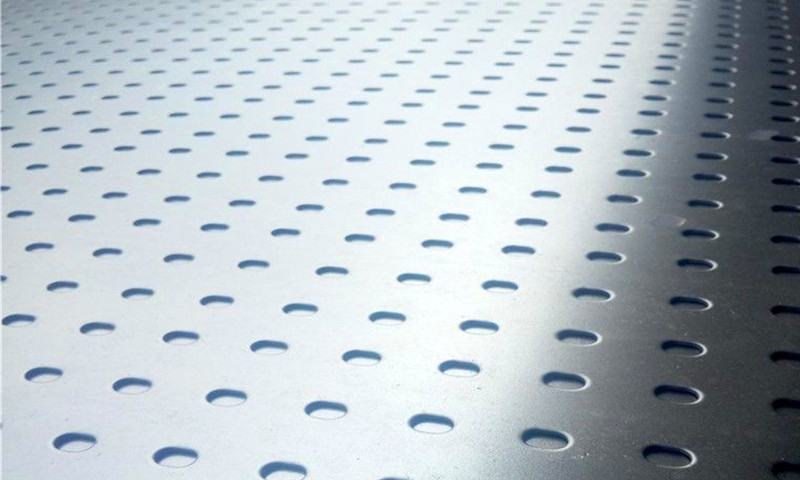

5. Impact of Hole Pitch on Pricing

Hole pitch (center‑to‑center distance) dictates the number of holes per square meter:

Large Pitch: Fewer holes, faster punching, lower Perforated Sheet cost.

Small Pitch: More holes, greater die wear, longer processing—higher Perforated Sheet pricing.

Adjust pitch to balance airflow, aesthetics, and Perforated Sheet budget.

perforated sheet

6. Influence of Order Quantity

Bulk orders spread setup costs over more units:

Small Batches (under dozens of m²): Higher unit cost for Perforated Sheet.

Large Orders (hundreds of m²+): Volume discounts and priority scheduling yield lower Perforated Sheet pricing.

Where possible, consolidate orders to secure the best Perforated Sheet rates.

perforated sheet

Conclusion

Perforated Sheet pricing hinges on material, thickness, dimensions, hole type, pitch, and order volume, as well as market metal prices and production schedules. Providing suppliers with detailed drawings and specifications ensures accurate quotes and helps you choose the most cost‑effective Perforated Sheet solution without compromising performance.