Characteristics of Fish Scale Perforated Plates in Screening Applications

Source:www.cn-psp.cnAuthor:河北森驰公司 Last updated:2025-04-09 14:21:41 Browse:

In the screening process, the use of perforated plates is critical. However, relying solely on perforated plates for material screening may lead to quality issues. These problems are influenced by various factors, and without correctly analyzing or identifying these factors, it can be challenging to resolve common screening difficulties.

The physical properties of materials during screening, such as particle size distribution and moisture content, significantly affect the efficiency of perforated plates in the screening process. Additionally, the properties of the screening surface and structural parameters also impact the performance of the perforated plates. In industrial applications, there is a tendency to use machines with high production capacity. To address these challenges, we have developed a new type of perforated plate—the fish scale perforated plate. It can change the movement pattern of materials, transforming the material flow from a laminar flow state near the screen surface to a more pulsating flow state. This product is mainly used for sample screening in feed mills.

Limitations of Traditional Perforated Plates

Traditional perforated plates are typically flat and smooth, with clear hole edges, and the hole axis is parallel to the material flow direction. However, in practical applications, conventional perforated plates may result in slow discharge, low output, high power consumption, and excessive crushing. These issues affect screening efficiency and production costs.

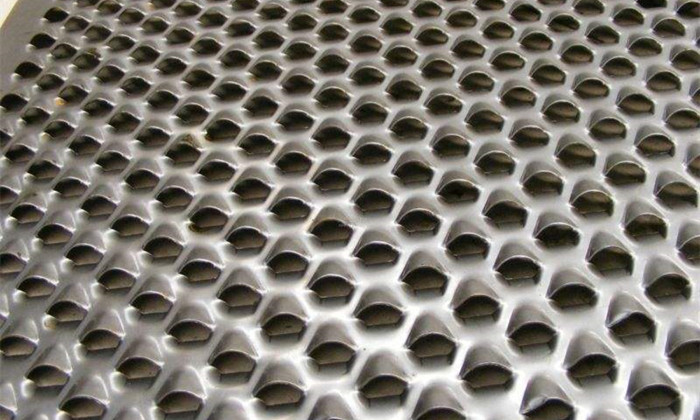

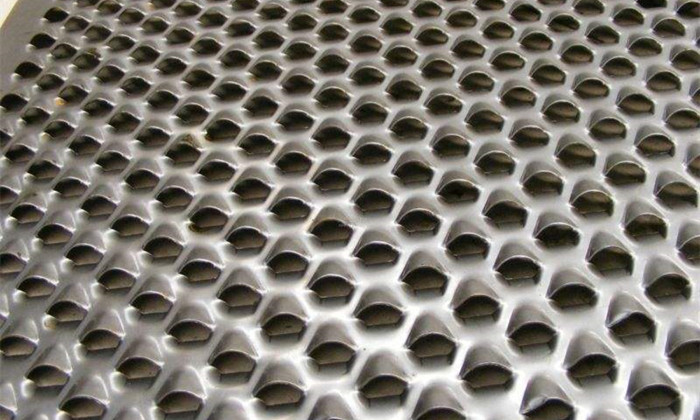

Innovative Design of Fish Scale Perforated Plates

To meet user demands, we have adopted fish scale perforated plates to enhance screening performance. The edges of the fish scale holes are raised and sharp, which causes the perforated plate to be installed opposite to the rotation direction of the hammer. This design shortens the distance between the hammer and the screen, thins the material flow layer, and reduces the resistance to material passing through the screen. At the same time, it increases the resistance to material movement, slowing down the flow rate of the material, allowing it to pass through the holes more efficiently, thereby improving the screening effect.

Fish Scale Perforated Plate

Advantages of Fish Scale Perforated Plates

Improved Material Movement: Fish scale perforated plates can transform material flow from laminar to pulsating flow, enhancing screening efficiency.

Reduced Material Resistance: The fish scale design reduces the thickness of the material flow layer, lowering the resistance when the material passes through the perforated plate, speeding up the screening process.

Enhanced Screening Effect: By installing the perforated plate opposite the rotation direction of the hammer, the fish scale perforated plate increases material movement resistance, slowing down the flow rate, ensuring the material passes through the holes more effectively for screening.

Applications and Benefits

Fish scale perforated plates are primarily used in sample screening in feed mills. They effectively solve issues such as slow discharge and high power consumption that arise with traditional perforated plates during the screening process. They are widely used in various screening fields. By adopting fish scale perforated plates, screening efficiency can be improved, and energy consumption in production can be optimized, making it a more efficient screening tool.

Conclusion

The innovative design of fish scale perforated plates offers significant advantages in material screening. By improving material movement patterns, reducing resistance, and enhancing screening efficiency, it provides a more efficient solution for screening tasks in industrial production. If you're looking for a highly efficient screening tool, fish scale perforated plates are undoubtedly an ideal choice.