Perforated Metal Panels in Ceiling Applications: Features and Benefits

Source:www.cn-psp.cnAuthor:河北森驰公司 Last updated:2025-04-03 10:24:57 Browse:

In modern architectural design, perforated metal ceiling panels have become a popular choice due to their unique functionality and aesthetic appeal. Whether in commercial buildings, public facilities, or residential spaces, these panels offer numerous advantages. This article explores their key features and application benefits.

1. Lightweight Structure for Easy Installation

Thanks to an advanced perforation process, perforated metal panels significantly reduce weight compared to solid metal sheets. This makes transportation, handling, and installation easier, while also reducing the load on the building’s structure.

2. High Strength and Impact Resistance

Made from durable metals such as aluminum, stainless steel, or galvanized steel, perforated panels boast superior strength compared to traditional ceiling materials like gypsum or PVC. They can withstand high pressure and impacts without deformation or damage, making them ideal for public and industrial spaces.

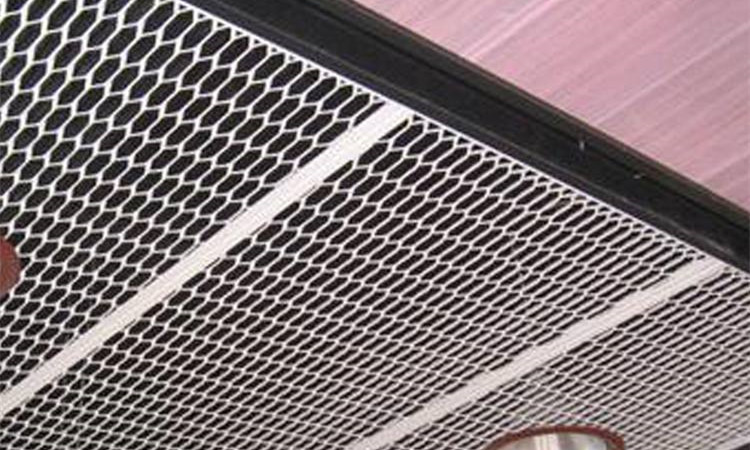

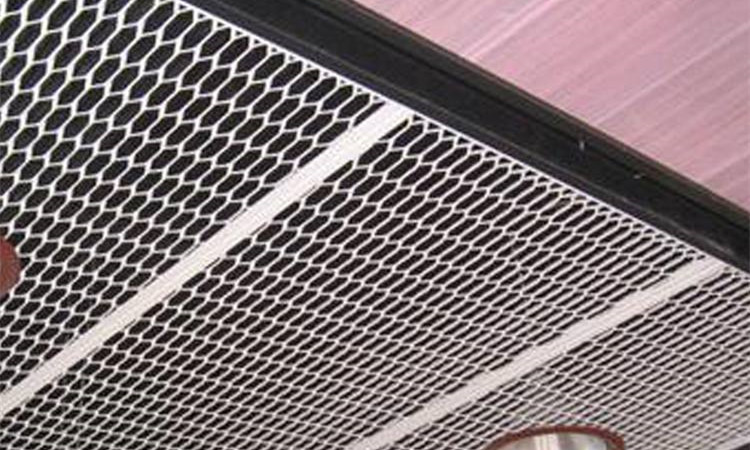

Perforated Panels

3. Corrosion Resistance and Long Lifespan

Perforated metal panels often feature powder coating or anodized finishes, which enhance their oxidation and corrosion resistance. This makes them suitable for humid or harsh environments, significantly extending their service life.

4. Pre-Fabricated for Efficient Construction

Perforated metal panels undergo punching, cutting, bending, and coating during factory processing. As a result, they arrive ready for immediate installation, minimizing on-site labor and construction time, improving efficiency, and reducing costs.

5. Eco-Friendly and Fully Recyclable

As a sustainable material, perforated metal panels are 100% recyclable, making them an eco-friendly option that aligns with modern green building standards. Additionally, they do not release harmful substances, contributing to a healthier indoor environment.

6. Fireproof for Enhanced Safety

Made entirely of metal, perforated ceiling panels are non-combustible and do not contribute to fire spread. They also do not release toxic fumes in case of a fire, making them a preferred choice for airports, subway stations, hospitals, shopping malls, and other high-safety environments.

Perforated Panels

7. Versatile Designs for Various Architectural Styles

Perforated ceiling panels can be customized into various shapes, including rectangles, squares, triangles, and irregular designs. They also come in a variety of colors and finishes, allowing for a high degree of design flexibility to complement different architectural aesthetics.

8. Multiple Perforation Patterns for Functionality & Aesthetics

Perforated metal ceilings offer a wide selection of hole patterns, including:

Standard Perforations: Round holes, square holes, rectangular holes, long round holes, triangular holes, hexagonal holes

Custom Perforations: Star-shaped holes, octagonal holes, cross holes, diamond-shaped holes, velvet holes, feather holes, and more

Perforated Panels

These patterns enhance visual appeal while also improving acoustics, ventilation, and natural lighting, making them especially suitable for theaters, concert halls, offices, and schools.

Conclusion

With lightweight construction, high durability, fire resistance, environmental friendliness, and versatile design options, perforated metal ceiling panels are an ideal choice for modern architecture. Whether you're looking for a stylish, durable, and functional ceiling solution, perforated metal panels offer the perfect combination of aesthetics and performance.