What Are the Specifications and Parameters of Metal Perforated Sheets?

Source:www.cn-psp.cnAuthor:河北森驰公司 Last updated:2025-03-06 15:32:17 Browse:

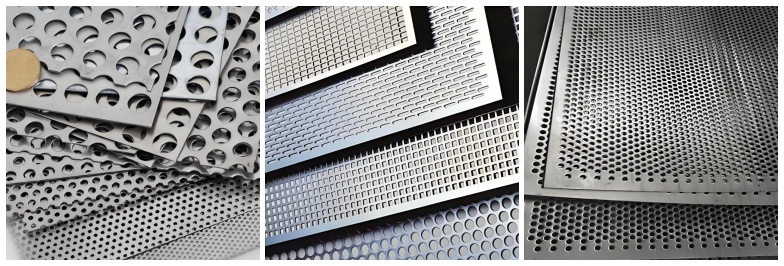

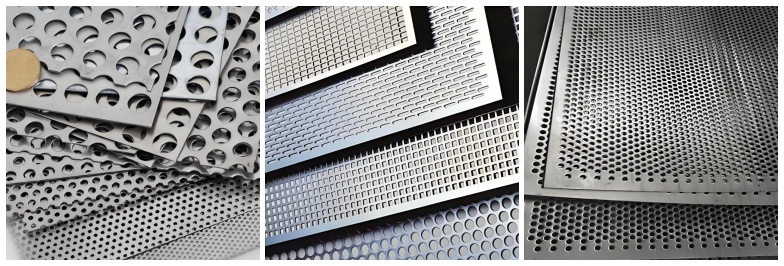

Metal perforated sheets are widely used materials, generally categorized into custom-made and stock perforated sheets. Stock perforated sheets are suitable for applications with less stringent requirements and come in limited standard specifications, offering fewer choices. Custom-made perforated sheets, on the other hand, can be tailored to meet specific user needs, making them more versatile and flexible in application.

Our factory specializes in the customized production of metal perforated sheets based on user requirements. Below is a detailed introduction to the available specifications and parameters for customization.

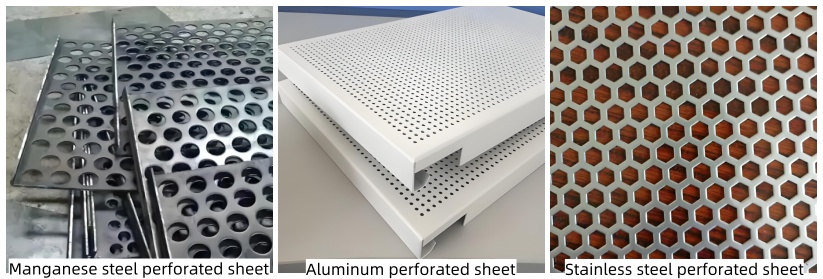

1. Material Selection

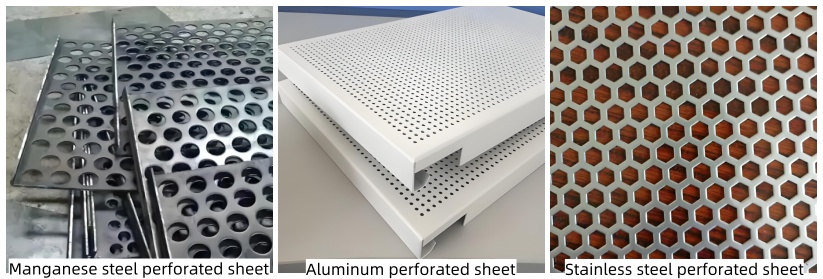

Metal perforated sheets come in a variety of materials, including:

Stainless Steel: Common stainless steel perforated sheet materials include 201, 2205, 304, 310S, 316, 316L, and 430. Stainless steel perforated sheets are highly resistant to corrosion, making them suitable for humid or corrosive environments. Surface finishes include cold-rolled 2B finish, brushed finish, electrolytic polishing, and mirror polishing.

Aluminum Sheet: Common aluminum perforated sheet materials include 1060, 3003, 3004, 5052, 5083, and 6061. Aluminum perforated sheets are lightweight and resistant to oxidation, making them ideal for decorative and lightweight structures. They can be treated with anodizing or electrostatic powder coating for enhanced corrosion resistance and various color options.

Galvanized Steel Sheet: Common galvanized perforated sheet zinc coating thicknesses include Z40, Z60, Z80, Z120, Z180, and Z275. These sheets offer excellent rust resistance, making them suitable for outdoor applications. Electrostatic powder coating can be applied to change colors with a variety of options.

Hot-Rolled Steel Sheet: Economical and wear-resistant, these sheets can be treated with hot-dip galvanization for corrosion protection, with a zinc coating thickness of up to 80μm.

Copper and Titanium Sheets: Used for specialized applications such as high-end decoration or high-temperature environments.

2. Thickness Range

The thickness of metal perforated sheets generally ranges from 0.3mm to 30mm. Common thickness specifications for different materials include:

Stainless Steel: 0.1mm - 30mm

Aluminum: 0.5mm - 30mm

Galvanized Steel: 0.2mm - 6mm

Manganese Steel: 3mm - 30mm

Cold-Rolled Steel: 0.5mm - 3mm

Hot-Rolled Steel: 1.5mm - 30mm

Perforated sheets must adhere to the minimum hole principle: for round holes, the hole diameter must not be smaller than the sheet thickness, while for other shapes, the minimum side length must not be less than the sheet thickness.

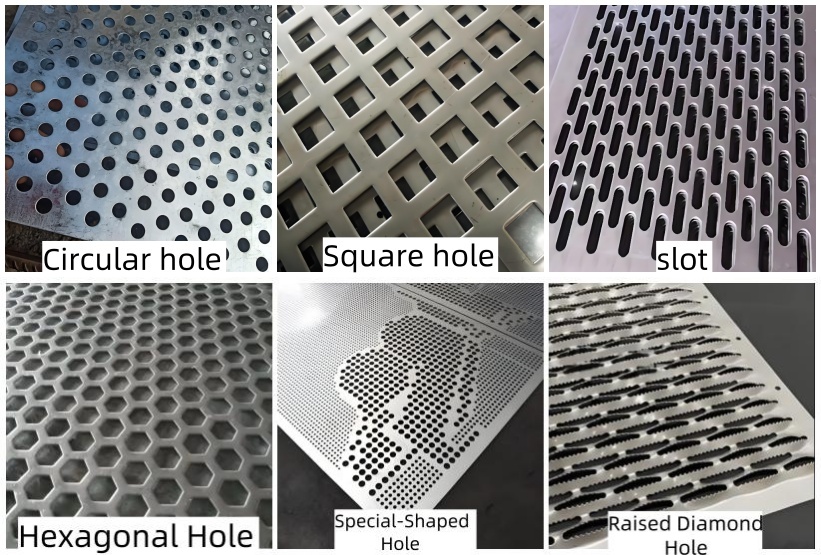

3. Hole Types and Diameters

Metal perforated sheets come in various hole patterns, including:

Round Holes (most common, diameter range: 0.5mm - 100mm)

Square Holes (commonly used for decoration or protective panels)

Slotted Holes (ideal for ventilation and drainage)

Hexagonal Holes (providing both aesthetic appeal and functionality)

Special-Shaped Holes (e.g., star-shaped, plum blossom-shaped, primarily for decorative use)

Raised Diamond Holes (commonly used in anti-slip stair treads)

The hole diameter is related to the open area ratio, which affects the permeability and strength of the perforated sheet. Typical open area ratios range from 10% to 50%.

4. Hole Spacing and Arrangement

Hole Spacing: The distance between the centers of adjacent holes, usually equal to or greater than the hole diameter.

Arrangement Methods:

60°Staggered (Hexagonal Pattern): Increases open area ratio and enhances strength.

90°Straight (Square Pattern): Common in decorative and industrial applications.

Custom Arrangement: Unique designs based on specific requirements.

5. Sheet Dimensions

Standard dimensions of metal perforated sheets vary by material:

Stainless Steel Perforated Sheets: 1000mm x 2000mm, 1220mm x 2440mm, 1500mm x 3000mm. Custom sizes are typically available for widths below 1500mm and lengths below 5000mm.

Aluminum Perforated Sheets: 1000mm x 2000mm, 1220mm x 2440mm, 1250mm x 2500mm, 1500mm x 3000mm. Custom sizes can be tailored within 1500mm in width and 5000mm in length.

Galvanized, Manganese, Cold-Rolled, and Hot-Rolled Steel Perforated Sheets: 1000mm x 2000mm, 1250mm x 2500mm, 1500mm x 3000mm. Custom sizes are also available with widths up to 1500mm and lengths up to 5000mm.

Conclusion

The specifications and parameters of metal perforated sheets include material selection, thickness, hole type, hole diameter, hole spacing, arrangement patterns, dimensions, and surface treatment options. When choosing a metal perforated sheet, it is essential to determine the appropriate parameters based on specific application needs to achieve the best functionality and aesthetics. We hope this information helps you select and utilize metal perforated sheets more effectively!