Standard Size Chart and Custom Size Introduction for Perforated Metal Panels

Source:www.cn-psp.cnAuthor:河北森驰公司 Last updated:2025-02-13 09:19:26 Browse:

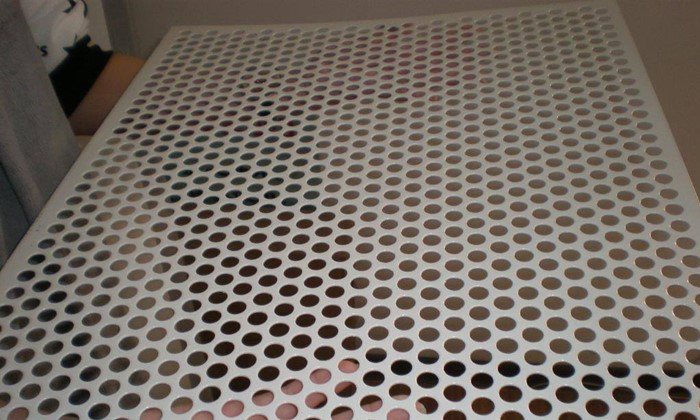

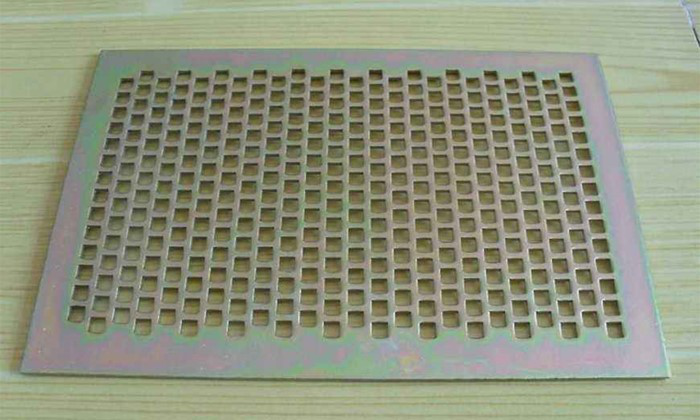

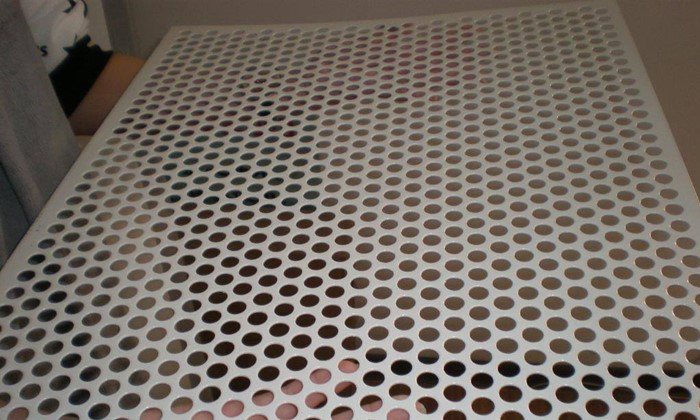

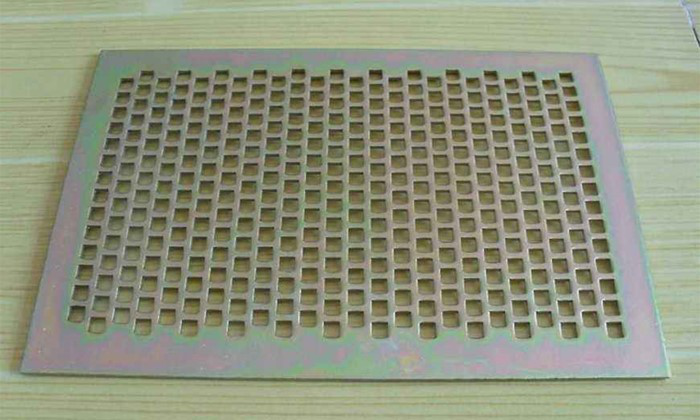

Overview of Perforated Metal Panels

Perforated metal panels are metal sheets with small holes arranged in a regular pattern. They are widely used in architectural decoration, acoustic engineering, industrial equipment, and other fields. Their main features include aesthetics, functionality, and excellent processing performance. This article will provide detailed information about the standard sizes and custom sizes of perforated metal panels.

Standard Size Chart for Perforated Metal Panels

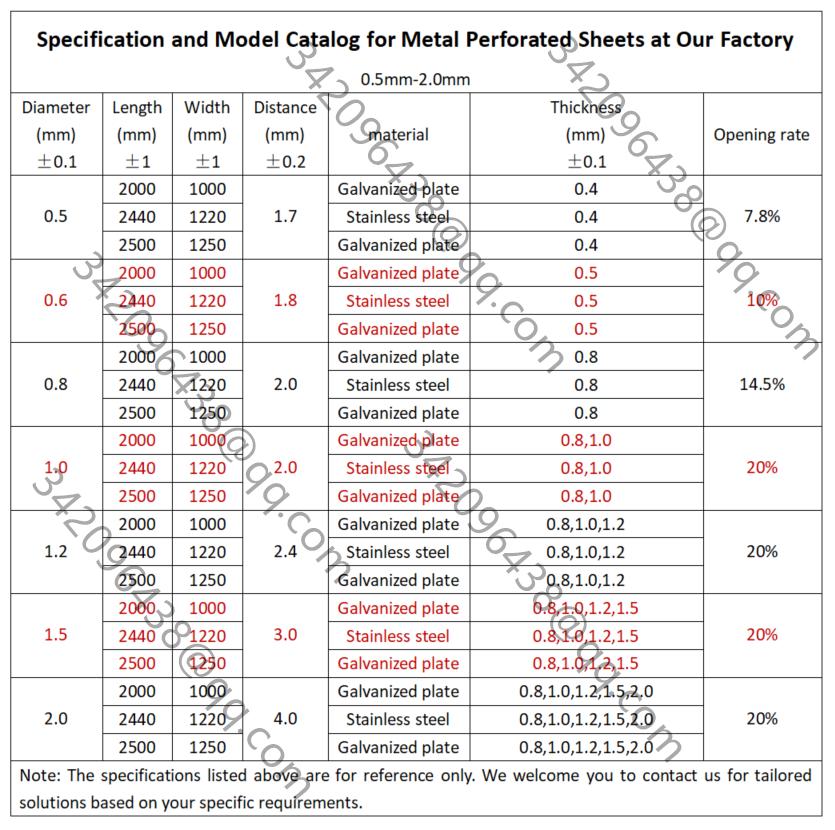

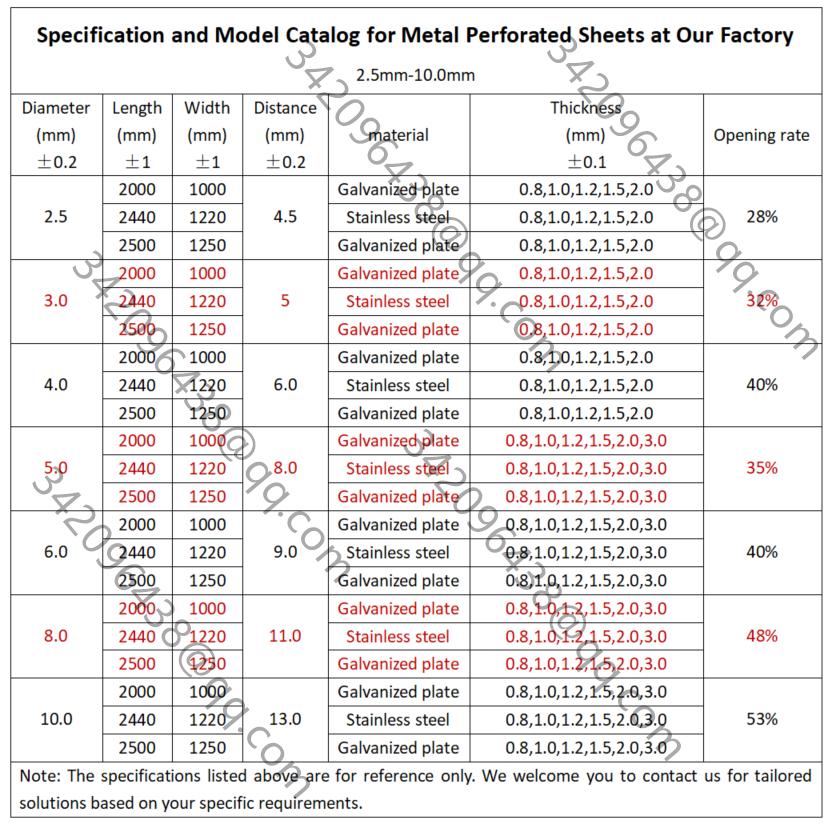

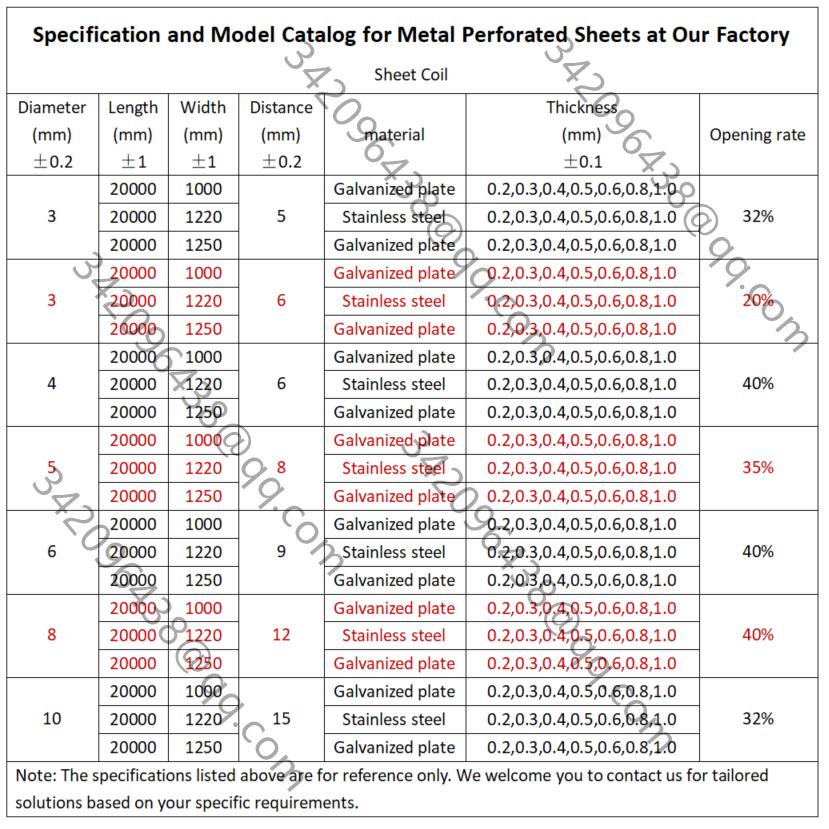

Below is a reference table of the standard sizes of perforated metal panels commonly available from our factory:

Explanation:

Thickness: Depending on the application scenario, the choice of thickness varies. For example, architectural decoration typically uses 0.8mm to 1.2mm thickness, while industrial equipment may require thicker sheets. However, we must adhere to the processing limit where the hole diameter must not be smaller than the sheet thickness (e.g., for a metal perforated panel with a round hole diameter of 3.5mm, the sheet thickness should not exceed 3.5mm).

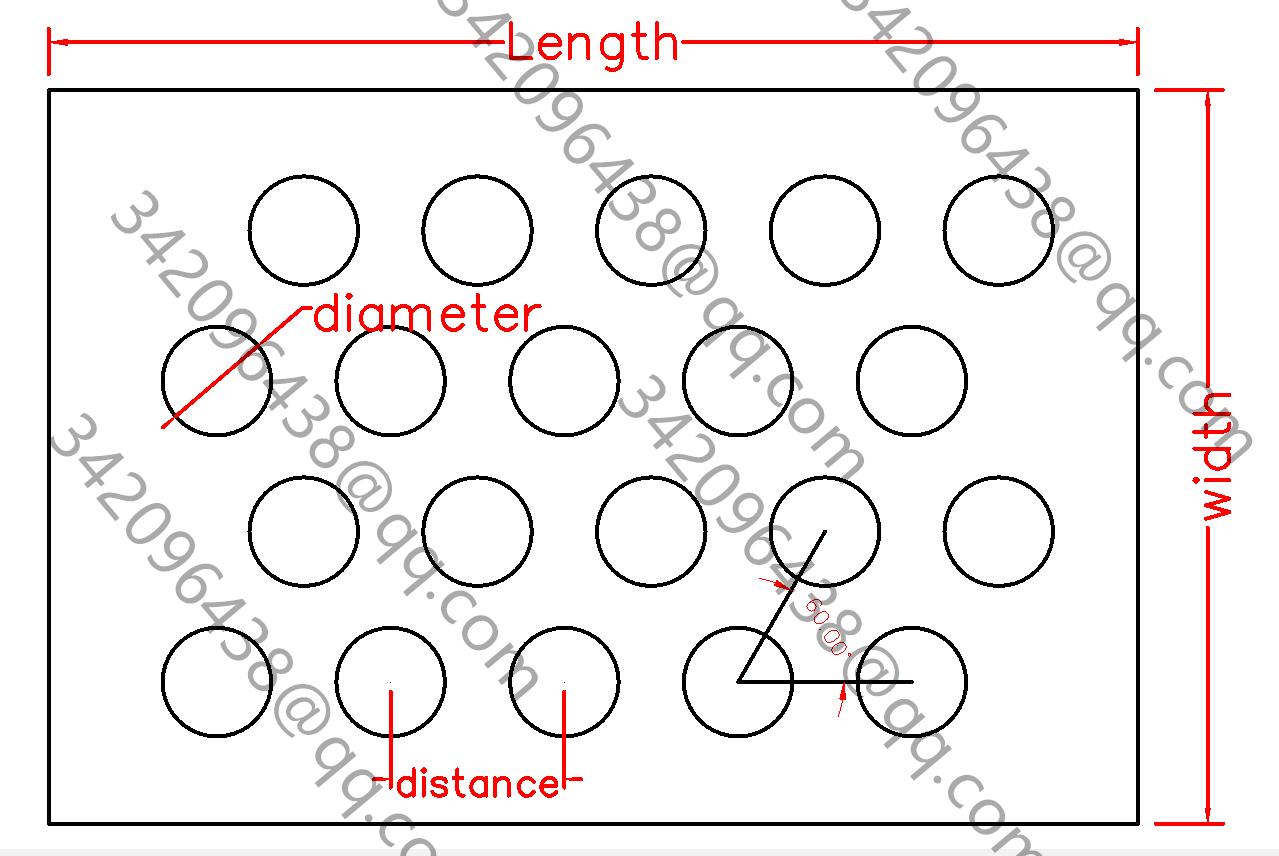

Hole Diameter and Pitch: The hole diameter and pitch directly affect the functional characteristics of the perforated metal panel (the edge thickness between two adjacent holes must not be less than the sheet thickness).

Panel Length and Width: Standard dimensions are usually set based on production efficiency and transportation convenience. However, our factory can adjust the dimensions according to customer needs. Generally, panels with widths less than 1500mm and lengths less than 4000mm can be customized.

Material and Hole Shape: We can process and customize most types of metal sheets available in the market, such as carbon steel sheets, galvanized sheets, manganese steel sheets, aluminum alloy sheets, stainless steel sheets, and copper sheets. Common hole shapes include round holes, slot holes, triangular holes, square holes, rectangular holes, louver holes, and anti-slip holes.

Surface Treatment: We can perform different surface treatments on metal perforated panels according to customer needs, such as painting, galvanizing, electropolishing, and anodizing.

Application Scenarios of Perforated Metal Panels:

Architectural Decoration: Commonly used for ceilings, wall decorations, etc., combining aesthetics and functionality.

Acoustic Engineering: Used as sound-absorbing or diffusing materials in recording studios, meeting rooms, etc.

Industrial Equipment: Used in the manufacture of ventilation systems, soundproof enclosures, etc.

Artistic Design: Custom shapes and surface treatments can be used to create unique artistic installations.

Suggestions for Selecting Perforated Metal Panels:

Based on Functional Requirements:

For sound absorption, focus on the design of hole diameter and pitch.

For decoration, prioritize appearance and surface treatment.

Considering Environmental Conditions:

Outdoor use requires materials with better weather resistance (e.g., galvanized sheets or stainless steel sheets).

In high humidity or corrosive environments, additional surface protection is needed.

Combining Budget and Schedule:

Standard sizes generally have lower costs and faster delivery times.

Custom sizes require more time and budget allocation.

Perforated metal panels are versatile materials with wide-ranging applications across multiple industries. Whether for standard sizes or custom dimensions, our factory can meet customer needs based on actual requirements. We hope this article provides valuable information to help you better understand and utilize perforated metal panels.

For further technical support or customized solutions, please feel free to contact our professional team at any time!