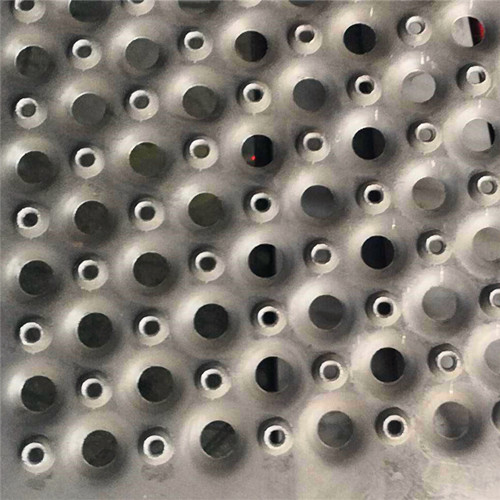

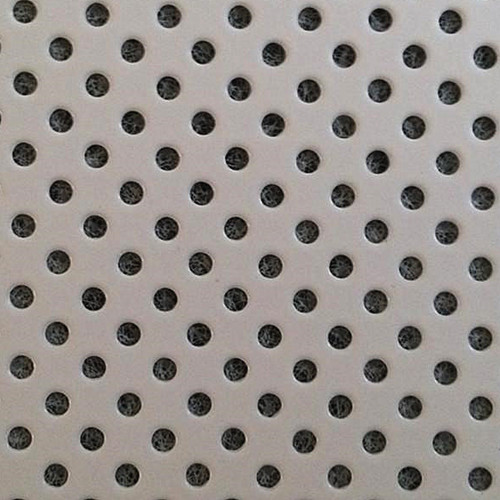

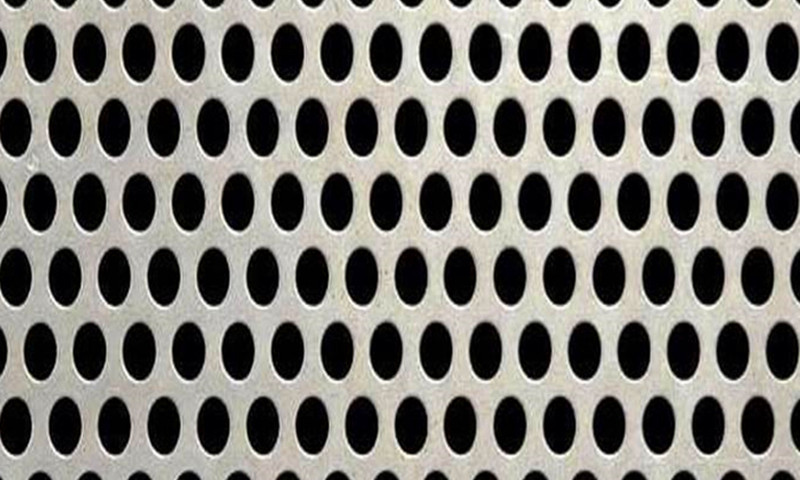

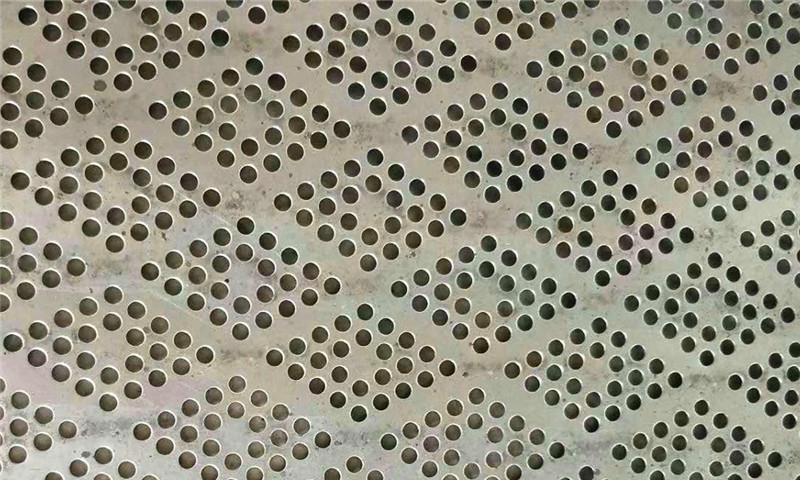

Aluminum alloy perforated panels are made from high-quality aluminum alloy sheets and processed through continuous punching using customized dies on CNC punching machines. These panels not only offer excellent visual appeal but also possess outstanding physical properties, making them an essential material in architectural decoration, industrial applications, and artistic design. Compared to regular aluminum sheets, aluminum alloy panels have significant advantages in terms of strength, corrosion resistance, and processing performance, which makes them suitable for more demanding applications.

Difference Between Aluminum Alloy Sheets and Regular Aluminum Sheets

Material Strength: Aluminum alloy sheets are made by alloying aluminum with other metals (such as silicon, copper, magnesium, etc.), giving them much higher strength than regular aluminum sheets. Aluminum alloy panels are ideal for applications that require load-bearing or resistance to pressure, while regular aluminum sheets are softer and are more suitable for lightweight decorative or non-structural uses.

Corrosion Resistance: Aluminum alloy panels offer superior corrosion resistance compared to regular aluminum sheets. The alloying elements in aluminum alloys form a strong oxide layer on the surface, which helps the panels resist moisture, acids, alkalis, and other corrosive elements, extending their lifespan. Regular aluminum sheets are more prone to corrosion, especially in harsh environments, and have a shorter service life.

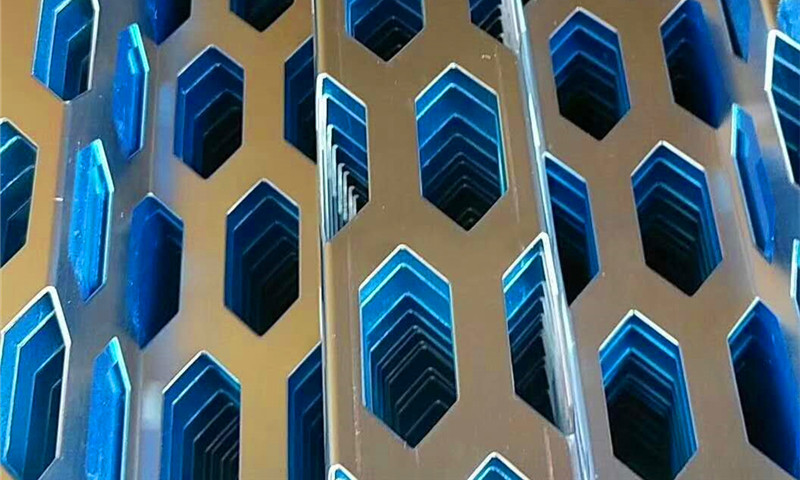

Processing Performance: Due to the optimized alloy composition, aluminum alloy sheets have better processing capabilities. They can be punched, bent, welded, and subjected to various surface treatments such as spraying, fluorocarbon spraying, electrostatic powder coating, and anodizing, ensuring both aesthetic appeal and durability. Regular aluminum sheets are simpler to process but lack the versatility and durability of aluminum alloy panels.

Weight and Load Capacity: Aluminum alloy panels have a higher density and better anti-compression and anti-bending properties compared to regular aluminum sheets. This makes them more suitable for structural applications where higher load-bearing capacity is required, such as in construction and transportation.

Aluminum Alloy Perforated Panels Specifications

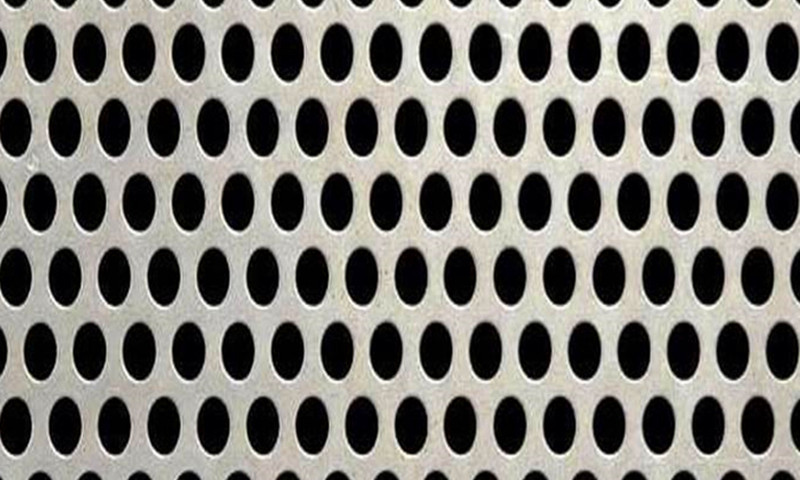

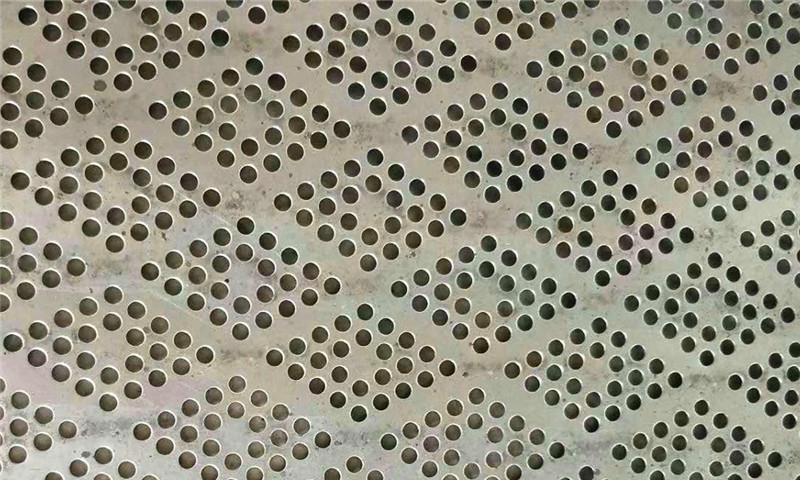

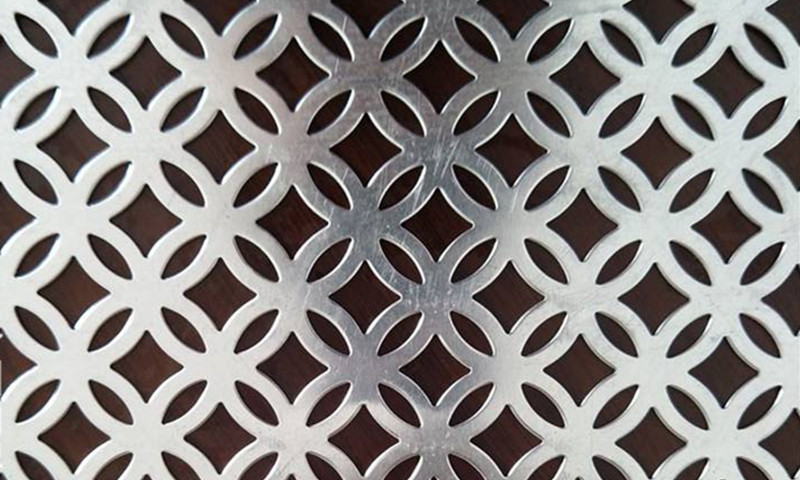

Aluminum alloy perforated panels come in a variety of specifications and models. They can be customized based on plate size, thickness, material, hole type, hole diameter, and other parameters. The available options for aluminum alloy perforated panels include:

Plate Size: Common sizes include 1m x 2m, 1.2m x 2.4m, 1m x 20m, and 1.2m x 20m. Custom sizes (width and length) are also available upon request.

Plate Thickness: The thickness can range from 0.1mm to 30mm.

Material: Aluminum alloy plate, regular aluminum sheet, and other materials are available.

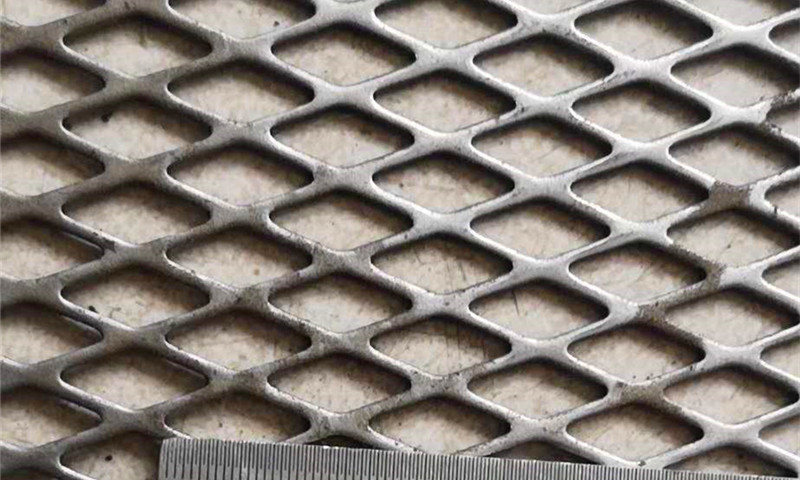

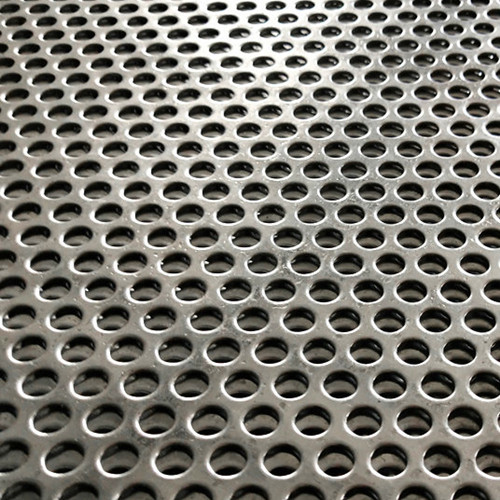

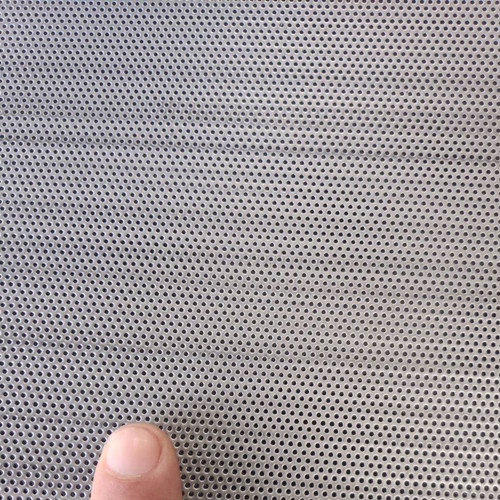

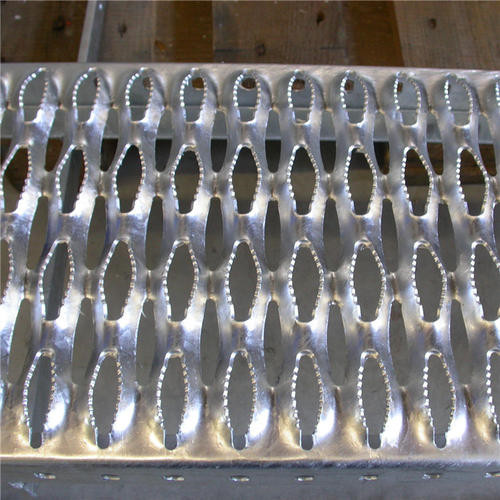

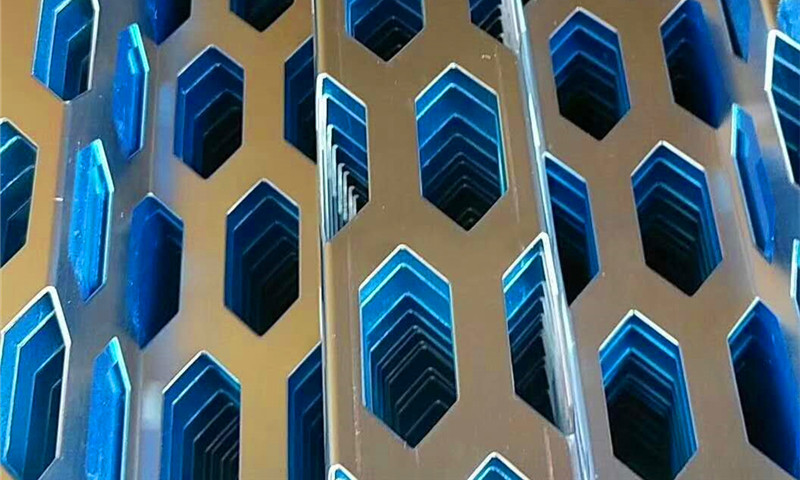

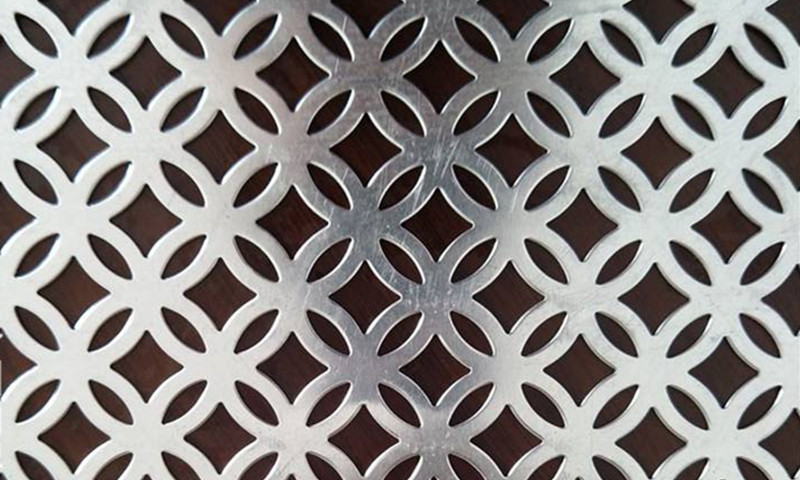

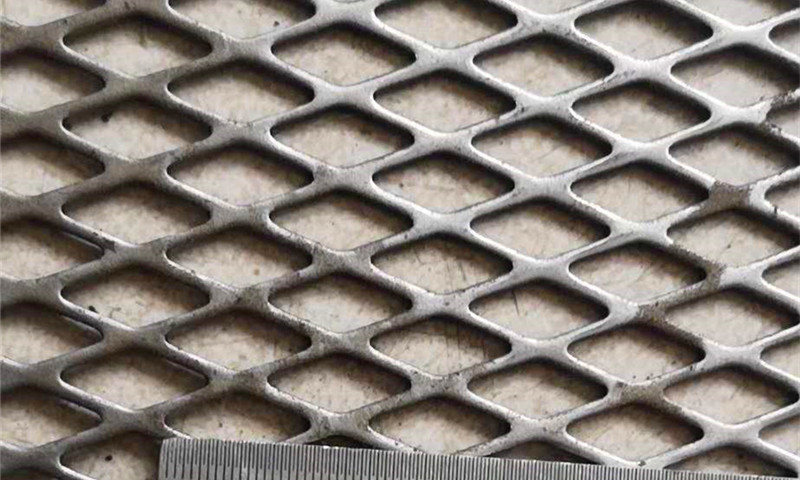

Hole Types: A wide variety of hole types can be customized, including round holes, oval holes, square holes, triangular holes, five-pointed star holes, hexagonal holes, figure-eight holes, cross holes, zigzag holes, diamond holes, fish scale holes, nail holes, bridge holes, louver holes, round drum holes, crocodile mouth holes, and more.

Hole Diameter: The hole size can range from 0.2mm to 300mm.

Surface Treatment: Surface treatments include spraying, fluorocarbon spraying, electrostatic powder coating, anodizing, and other options to enhance appearance, corrosion resistance, and durability.

Applications of Aluminum Alloy Perforated Panels

Due to their strength, corrosion resistance, and aesthetic appeal, aluminum alloy perforated panels are widely used in various industries and fields:

Construction Industry: Aluminum alloy perforated panels are commonly used in exterior wall cladding, curtain walls, ceiling panels, partitions, and decorative mesh, adding aesthetic value to buildings while improving durability.

Industrial Sector: In functional applications such as ventilation, soundproofing, and protection, aluminum alloy perforated panels are ideal due to their high resistance to high temperatures and corrosion.

Artistic Design: The unique hole patterns and surface finishes make aluminum alloy perforated panels a popular choice for artistic installations and creative designs, offering high decorative value.

Aluminum Alloy Perforated Panels Price Introduction

The price of aluminum alloy perforated panels varies depending on the specifications, models, hole types, hole diameter, surface treatment, and other factors. To get an accurate quote, please contact us with your specific requirements. You can send us an email detailing the specifications and quantity you need, and we will provide a precise quotation.

Why Choose Our Aluminum Alloy Perforated Panels?

Highly Customizable: We offer flexible customization services, tailoring aluminum alloy perforated panels to meet specific requirements in terms of size, material, thickness, hole type, hole diameter, and more.

Superior Performance: Compared to regular aluminum sheets, aluminum alloy perforated panels offer higher strength, better corrosion resistance, and a longer service life, making them ideal for more demanding applications.

Global Supply Chain: We are capable of supplying high-quality aluminum alloy perforated panels worldwide, ensuring timely delivery to meet the needs of projects in different regions.

Quality Assurance: We adhere to strict international quality standards, ensuring that every aluminum alloy perforated panel meets customer expectations for durability and aesthetics.

Professional Service: Our team is dedicated to providing comprehensive support, from product customization and technical advice to after-sales service, ensuring the smooth completion of your projects.

Contact Us

If you require customized aluminum alloy perforated panels or would like to learn more about our products, please don't hesitate to contact us. We will provide you with professional technical consultations and accurate quotations, helping you achieve the success of your project.