Key Factors Affecting the Price of Stainless Steel Perforated Mesh

Source:www.cn-psp.cnAuthor:河北森驰公司 Last updated:2025-04-17 10:15:30 Browse:

In modern industrial production and architectural decoration, stainless steel perforated mesh (also known as perforated stainless steel panels) is highly favored for its corrosion resistance, high strength, and wide range of applications. However, the market price of stainless steel perforated mesh is far from fixed, being influenced by multiple interrelated factors. This article dives deep into ten major dimensions that impact the pricing of stainless steel perforated mesh, helping you make informed procurement decisions, select the right specifications, and reduce costs effectively.

1. Fluctuations in Raw Material Prices

Stainless steel raw materials (such as 304, 316, 201, etc.) are closely tied to international commodity markets. Price trends both domestically and globally directly affect product pricing.

Tight supply chains or excess inventory can cause base prices to rise or fall.

Suggestion: Monitor price adjustment notifications from steel mills before bulk purchases, and consider locking in material costs via monthly or quarterly contracts.

Stainless Steel Perforated Mesh

2. Specification Dimensions and Cutting Methods

Common mesh widths: 1.0m, 1.2m, 1.5m; recommended length ≤2.5m to ease transportation and processing.

Non-standard widths or extra-long cuts require secondary processing, leading to material waste and higher labor costs.

Choosing standard sizes can effectively reduce order costs and shorten lead times.

3. Material Grades and Performance Differences

430 Stainless Steel: Mainly decorative, lower cost.

Select the appropriate grade based on usage environment and corrosion requirements to avoid subpar materials.

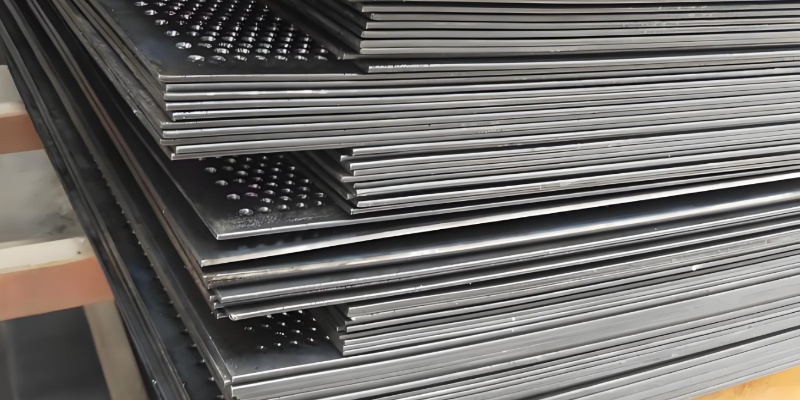

Stainless Steel Perforated Mesh Thickness Display

4. Mesh Thickness and Processing Costs

Typical thickness range: 0.5mm–5.0mm. Thicker mesh offers greater strength but also increases material and punching costs.

Too thin may deform; too thick is harder to process. Consult with manufacturers to choose the optimal thickness.

5. Hole Design and Production Efficiency

More complex holes demand higher machine precision and mold investment, reducing production speed and raising unit cost.

Balance aesthetics with economy by prioritizing standard hole patterns.

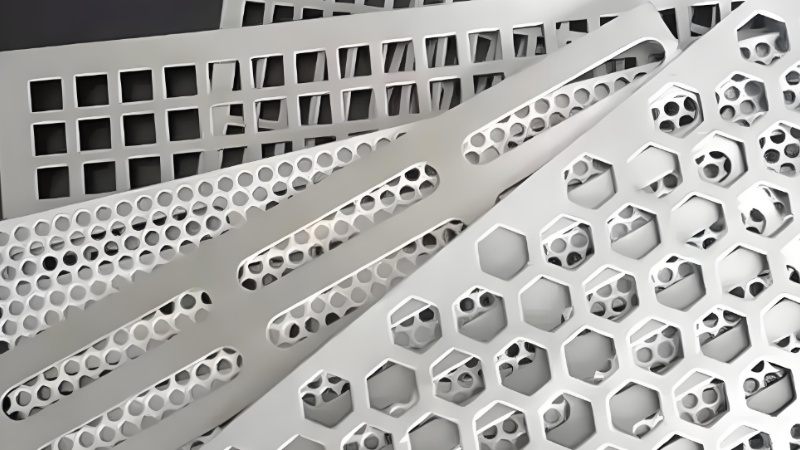

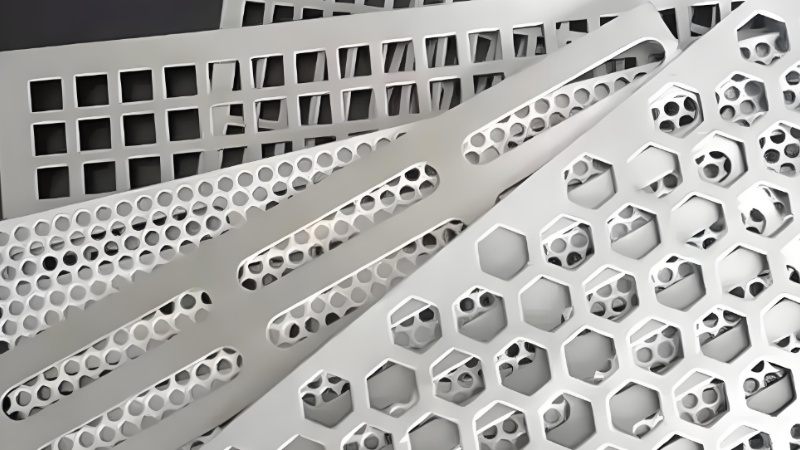

Stainless Steel Perforated Mesh Hole Patterns Display

Open area ratio = Hole area ÷ Total area. The higher the ratio, the more scrap material generated, reducing material utilization.

Larger holes and shorter spacing improve ventilation and light transmission but increase difficulty and cost.

Adjust the open area based on functional needs to maintain cost efficiency.

7. Surface Finishing Techniques

Sandblasting/Brushed: Fingerprint-resistant, stylish, moderately priced.

Mirror Polishing: High gloss, attractive finish, but time-consuming.

Electropolishing: Enhances corrosion resistance and brightness, highest processing cost.

Different finishes affect surface smoothness and corrosion performance—match with design goals and budget.

Stainless Steel Perforated Mesh Equipment Display

8. Secondary Processing and Additional Procedures

Processes like bending, stamping, rolling, and laser cutting require extra equipment and mold investment.

Welding, assembly, or splicing also add labor and inspection costs.

9. Bulk Orders and Customization Requirements

Bulk purchases usually offer lower unit prices.

Small or custom orders involve frequent machine adjustments and high scrap rates, leading to higher pricing.

Plan procurement smartly—opt for unified sizes and hole types for bulk manufacturing.

10. Logistics, Location, and Brand Influence

Transportation: Costs rise with distance; remote deliveries are more expensive.

Brand & Certification: Manufacturers with ISO9001, CE, SGS certifications may offer higher quality but come with a pricing premium.

Delivery Time: Rush orders may require overnight or extra production shifts, adding to costs.

Conclusion

The pricing of stainless steel perforated mesh is affected by various intertwined factors: raw material trends, mesh size, material grade, thickness, hole design, surface treatment, processing complexity, order volume, logistics, and brand reputation. As a buyer, you should:

Understand your needs: Know your application scenarios and corrosion resistance requirements.

Prioritize standard specs: Save on cutting and machine adjustment costs.

Plan bulk orders: Leverage economies of scale for better pricing.

Compare quotes: Focus on manufacturer qualifications, reputation, and after-sales support.

Lock material costs: Use framework agreements or hedging tools to manage market volatility.

By mastering these points, you can achieve optimal cost-performance without compromising quality. We hope this guide supports your procurement and project budgeting!