Comprehensive Analysis of Stainless Steel Perforated Plate Production and Leveling Techniques

Source:www.cn-psp.cnAuthor:河北森驰公司 Last updated:2025-03-28 08:54:56 Browse:

As a professional manufacturer of metal perforated plates in various specifications and models, we are committed to providing customers with high-quality stainless steel perforated plate products. This article will thoroughly introduce the production process of stainless steel perforated plates, common hole patterns, causes of deformation, and leveling treatment solutions, aiming to help users fully understand the product features and process details.

Stainless Steel Perforated Plate Production Process

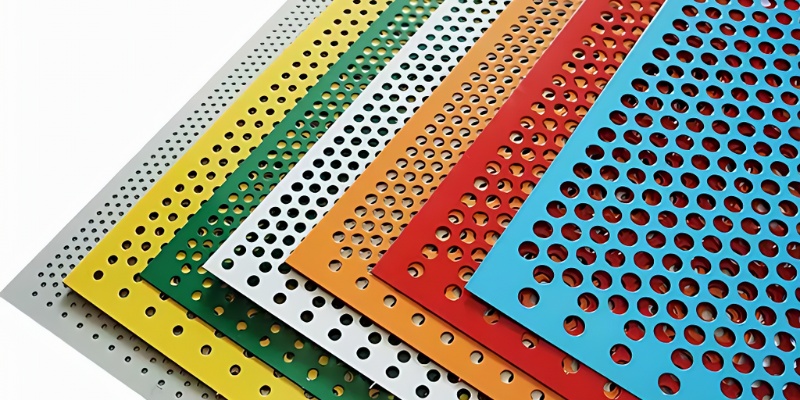

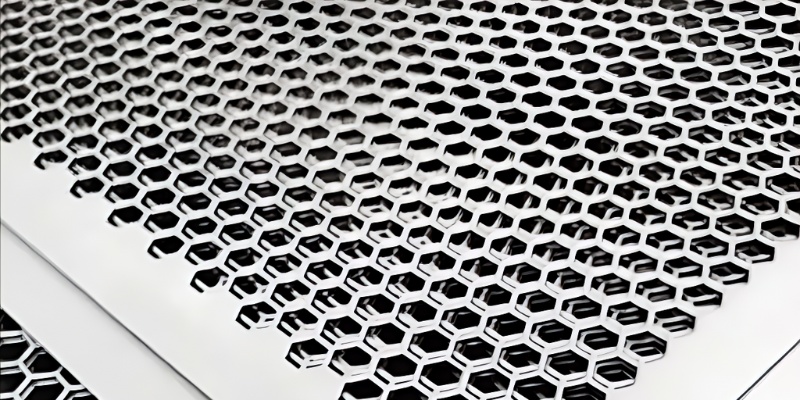

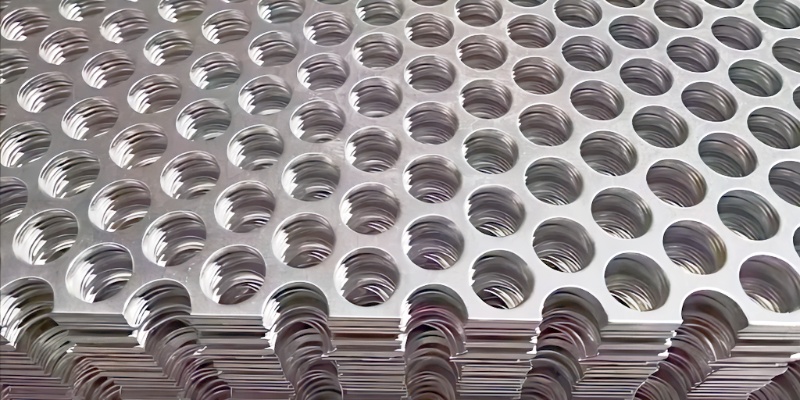

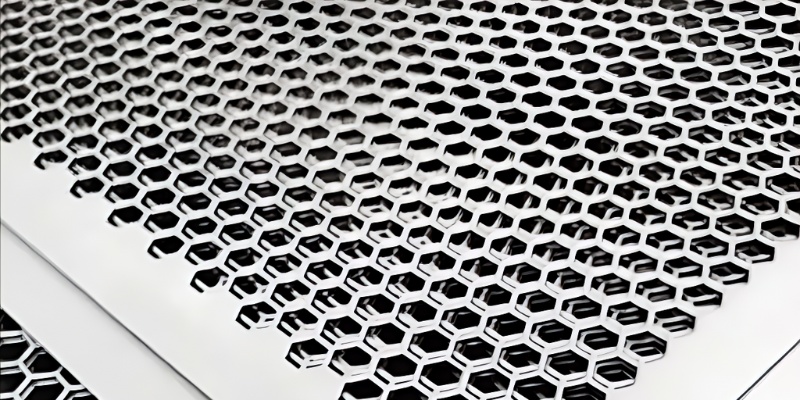

Stainless steel perforated plates are a type of mesh product made by continuously punching holes in stainless steel sheets using CNC punching machines and customized molds. During production, by precisely controlling the punching speed and pressure, various shapes of holes can be punched on the stainless steel sheet, such as:

Circular, oval, and oblong holes

Square and rectangular holes

Triangular, pentagonal, hexagonal, and cross-shaped holes

Other complex patterned holes

This diversified hole design gives stainless steel perforated plates wide applications in architectural decoration, industrial screening, ventilation and sound insulation, as well as protective decoration. Their low cost, reliable quality, strong corrosion resistance, and excellent acid and alkali resistance have made them highly popular among users.

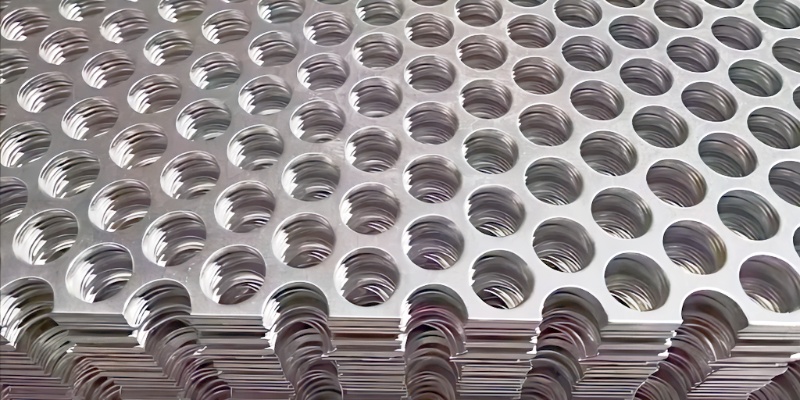

Possible Plate Deformation during Production

In actual production, some users have reported that the flatness of stainless steel perforated plates does not meet expectations and that there is slight deformation. In fact, this is mainly related to the following factors:

Open Area Ratio

The open area ratio of the perforated plate directly affects the stress distribution on the plate. The higher the open area ratio, the more concentrated the stress during punching, and the higher the possibility of plate deformation.

Wear of the Punching Pin

During long-term use of CNC punching machines, mold wear can exacerbate the uneven stress distribution along the hole edges, leading to more obvious deformation. Regular inspection and replacement of worn components is an important measure to control deformation.

Mold Gap Settings

During production, the gap between the upper and lower molds needs to be reasonably adjusted according to the thickness of the plate. If the gap is too large, it will cause uneven stress distribution during punching, resulting in significant deformation. Using precision molds and scientifically set gaps can effectively reduce this risk.

Differences in Plate Material

Different grades of stainless steel sheets (such as 201, 304, 316, 316L, etc.) have varying hardness, and their resistance to deformation also differs. Selecting the appropriate raw material based on specific process requirements will help improve product flatness.

Edge Margin Size

In the production process, to ensure the integrity of the plate edges, an edge margin of 1-2 centimeters is usually retained. If the customer requires a larger edge margin (for example, more than 10 centimeters), it becomes difficult to completely correct during subsequent leveling; the larger the edge margin, the higher the overall risk of deformation.

Leveling Treatment and Quality Improvement Solutions

For most specifications of stainless steel perforated plates, using dedicated leveling machines and advanced correction equipment can effectively rectify the slight deformation caused by the punching process. However, due to design or process limitations, some specifications may not be completely level. In such cases, we recommend that customers discuss product specifications and usage requirements in detail before placing an order to ensure the best solution is provided.

Furthermore, we continuously optimize the process flow and equipment technology, controlling the punching parameters and mold precision from the source, striving to minimize plate deformation while maintaining high production efficiency, and ensuring that our products always meet international quality standards.

Application Areas and Customer Service

Thanks to its excellent physical and chemical properties, stainless steel perforated plates are widely used in:

Architectural decoration and curtain wall design

Ventilation, sound insulation, and protective facilities

Industrial screening and mechanical filtration

Home and office space decoration

As a professional manufacturer of stainless steel perforated plates, we not only offer standard products but also support customized personalized designs. Whether it is the product shape, hole pattern, or special sizes, we can provide customized services based on customer requirements. At the same time, we have a comprehensive after-sales service system to ensure that customers receive timely and professional technical support during the product usage process.

Summary

Through scientific production processes and strict quality control, we fully consider product flatness and overall quality during the manufacturing of stainless steel perforated plates. Whether it is the hole pattern design, deformation control during production, or leveling treatment and customized customer service, we are committed to providing the highest quality product experience. By choosing us, you will enjoy high cost performance, stable performance, and comprehensive technical support.

The above content provides you with a detailed introduction to the entire process of stainless steel perforated plate production and quality control. If you have any further questions or need more detailed information about the product, please feel free to contact us for professional technical support and customized services.