2025-06-14

2025-06-07

2025-05-19

2025-05-13

2025-04-11

2025-06-14

2025-01-10

2025-05-19

2025-03-04

2025-05-21

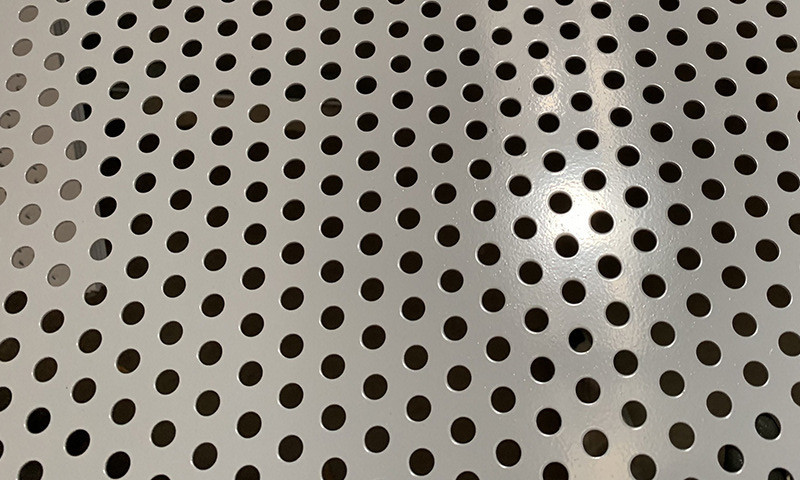

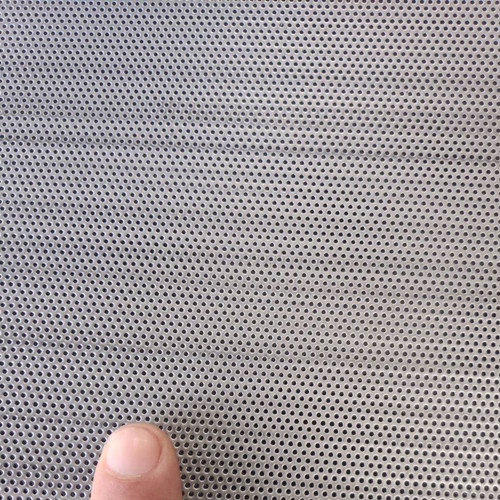

Small Hole Sieve Sheet

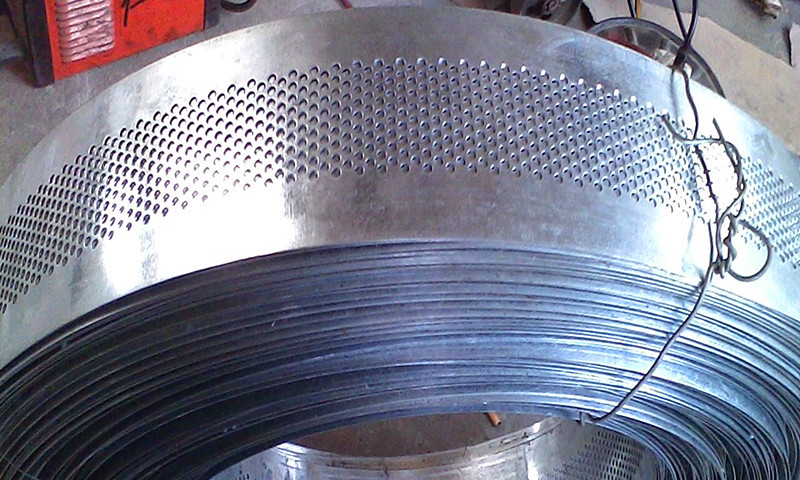

Concentric circular sieve plate

Metal Safety Grating

Grain Sorting Screen Plate

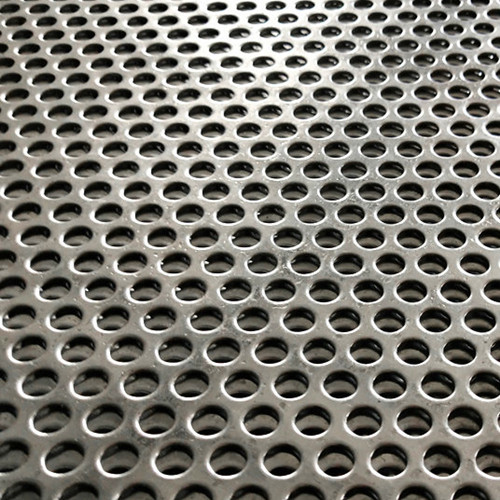

Stainless Steel Sieve Sheet

Stainless Steel Grip Strut Safety Grating

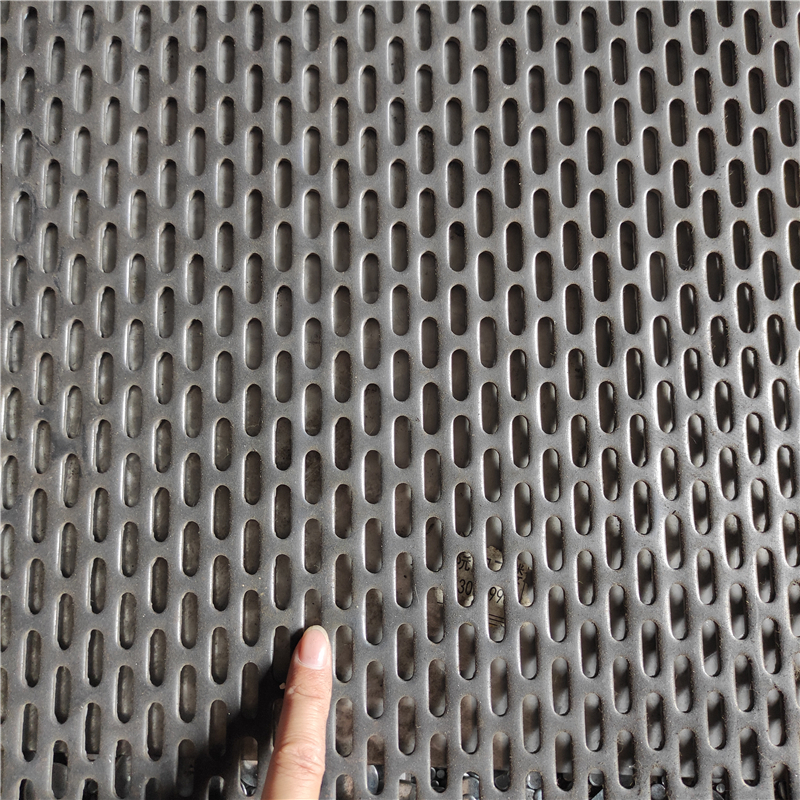

Obround Hole Sieve Sheet

Aluminium Grip Strut Safety Grating

Anti-skid Stair tread plate

Grip Strut Safety Grating

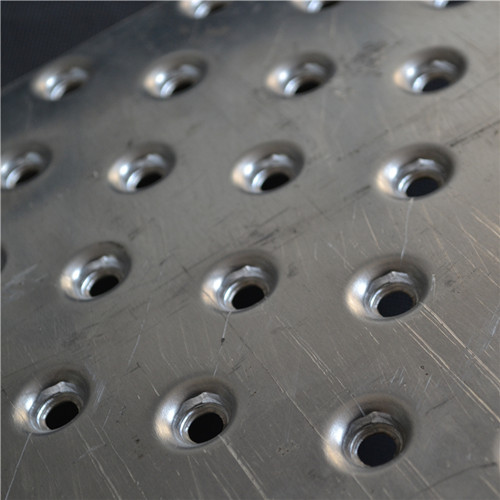

Convex Hole Anti-skid Plate

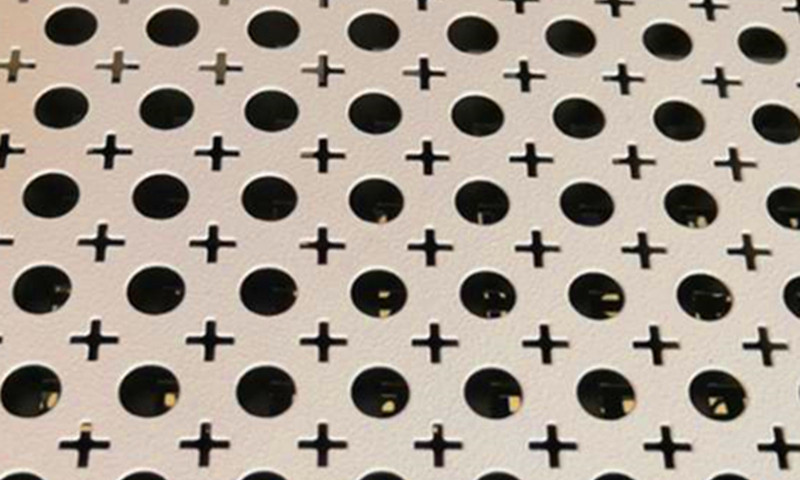

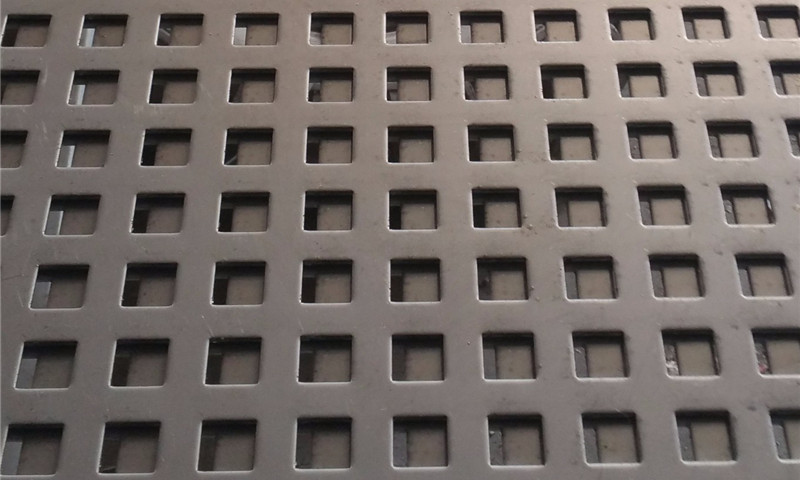

Carbon Steel Punched Metal Plate

Steel Grip Strut Safety Grating

Convex Hole Grip Strut Safety Grating

Carbon Steel Perforated Sheet