How to Maintain Stainless Steel Perforated Sheets

Source:www.cn-psp.cnAuthor:河北森驰公司 Last updated:2025-03-04 10:39:01 Browse:

Stainless steel perforated sheets are versatile materials used in a wide range of applications, from functional screens and ventilation grilles to decorative panels. Proper maintenance is essential to ensure these sheets continue to perform well and retain their aesthetic appeal over time. Here are some practical maintenance tips for stainless steel perforated sheets to help extend their lifespan and maintain their quality:

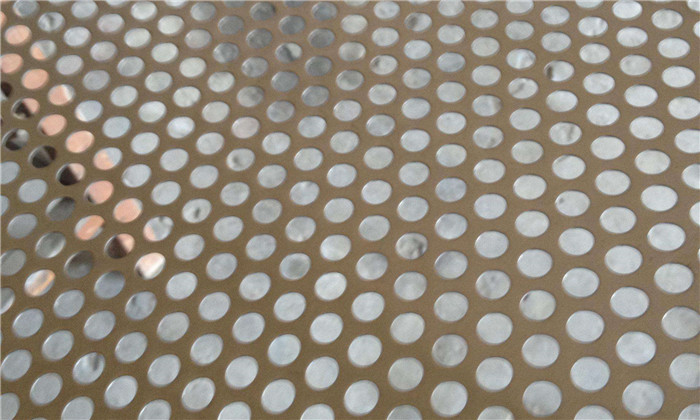

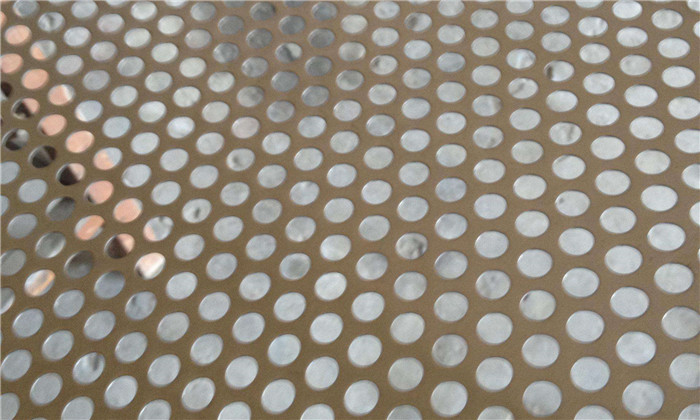

Stainless Steel Perforated Sheet

Regularly Clean the Perforations

When stainless steel perforated sheets are used for functional purposes, such as filtration or ventilation, it is crucial to prevent debris buildup in the holes. Over time, dust, dirt, grease, and other contaminants can accumulate inside the perforations, leading to blockages that may affect airflow or filtering efficiency. Regular cleaning is essential to ensure optimal performance. Using compressed air or a soft brush can help remove particles from the perforations without damaging the surface.

Protect from Physical Damage

If the stainless steel perforated sheet is used in decorative applications, extra care should be taken to protect it from physical damage. Avoid exposure to heavy impacts, sharp objects, or abrasives that could cause dents, scratches, or deformation. Even minor damage can detract from the sheet's visual appeal and, in some cases, compromise its structural integrity. Handling the sheet with care during installation and maintenance is key to preserving its look and function.

Prevent Corrosion and Rusting

While stainless steel is known for its resistance to rust due to the presence of chromium, it is not entirely immune to corrosion. In coastal areas with high salt content in the air, or in environments where the sheet comes into contact with acidic or alkaline substances (such as food juices, cleaning chemicals, or lime water), the protective oxide layer on the surface can be damaged. Once this layer is compromised, the material becomes vulnerable to rust and corrosion.

To prevent this, regularly inspect the stainless steel perforated sheet for signs of rust or discoloration. If the sheet is installed in a harsh environment, consider additional protective measures, such as coating or sealing the surface, to enhance its durability against environmental factors.

Safe Cleaning Methods

For routine cleaning, avoid harsh chemicals, abrasive tools (like steel wool), or bleach, as they can scratch or tarnish the surface. Instead, use mild soap water, a soft cloth, or a gentle cleaning brush. For stubborn stains or corrosion, you can use a specialized stainless steel cleaner that is safe for the material. After cleaning, always rinse the sheet thoroughly with clean water to remove any cleaning residues.

Addressing Minor Corrosion

If minor corrosion or stains occur, use a non-abrasive cleaner and a soft cloth to gently remove the marks. For more significant rust spots, a rust remover specifically designed for stainless steel can help restore the sheet’s surface. In some cases, a light polishing with a stainless steel polish may be needed to bring back the sheet’s shine and appearance.