How to Ensure the Precision of Stainless Steel Perforated Sheet?

Source:www.cn-psp.cnAuthor:河北森驰公司 Last updated:2025-03-04 10:39:33 Browse:

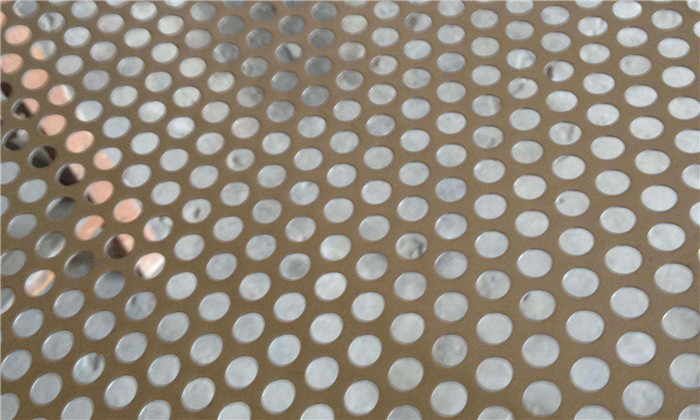

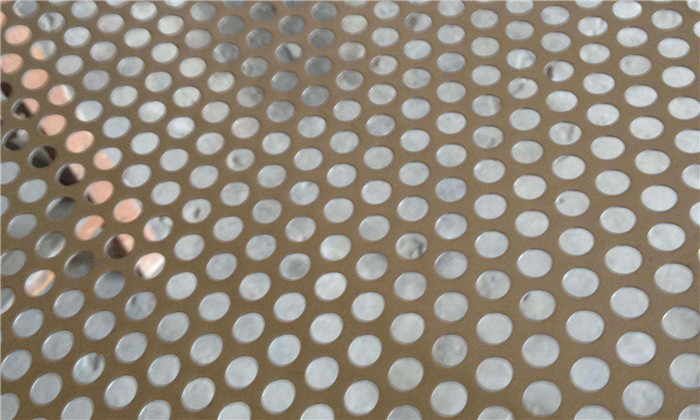

A Stainless steel Perforated sheet is a mesh product produced by continuously punching stainless steel plates using CNC punching technology. It is known for its precise hole patterns, smooth surface, durability, corrosion resistance, and resistance to acid and alkali, making it highly favored across various industries. In order to ensure high precision and quality in our Stainless steel Perforated sheets, we have implemented a series of strict production management measures. Below are the key practices we follow to guarantee the precision of our products during the manufacturing process:

Stainless steel Perforated sheet

Daily Maintenance and Inspection of CNC Punching Machines

Our CNC punching machines undergo comprehensive lubrication before starting each day of production, ensuring the smooth operation of all moving components. During the lubrication process, we specifically inspect critical parts such as the punch, lead screw, and feeder for any gaps. If any gaps are found to be out of specification, immediate adjustments or replacements are made to prevent any issues that could affect the punching accuracy.

Strict Control of Sheet Material Fixing

When securing the stainless steel sheets on the feeder, we perform repeated checks to ensure the sheets are positioned correctly. We also carefully check the pressure and force of the fixing tools to ensure they are sufficient to hold the sheets securely in place. This prevents any shifting of the material during production, which could otherwise affect the hole pattern precision.

Regular Inspection and Maintenance of Molds

After every mold change, the mold is sent to a specialized inspection department for thorough examination. We check that the hole size and gap dimensions meet the required standards. Regular inspections and adjustments to the molds ensure that every punching operation maintains consistent hole patterns and precision.

Sharpening and Regular Replacement of Punching Pins

We use CNC grinding machines to finely sharpen the punching pins, maintaining their sharpness and precision. In addition, we regularly replace the punching pins to prevent issues such as wear or burr buildup, which could affect the surface quality and hole accuracy of the Stainless steel Perforated sheets.

Through these measures, we effectively ensure that every batch of Stainless steel Perforated sheets has precise hole patterns and a smooth surface. Shenchi Perforated Mesh Factory is committed to adhering to the principle of "Quality First" and strives to provide high-quality products and services. We hope to cooperate with more customers for mutual success and growth.