Common Causes and Control of Burrs on the Back of Stainless Steel Perforated Sheets

Source:www.cn-psp.cnAuthor:河北森驰公司 Last updated:2025-06-07 15:07:57 Browse:

Burrs appearing on the back of stainless steel perforated sheets during production are a common and normal occurrence. These burrs primarily result from the shearing action of dies during the punching process. Due to the toughness and ductility of stainless steel, when subjected to high pressure, tearing effects occur during shearing, creating burrs on the reverse side. The size and shape of these burrs can vary depending on the production process, die condition, and material characteristics.

Causes of Burr Formation

During the punching process, factors such as die clearance, punching speed, material thickness, and die wear can significantly influence burr formation. For instance, excessive die clearance or heavily worn dies can lead to rough shear surfaces, resulting in larger burrs. Additionally, the hardness and ductility of stainless steel itself also play a critical role in burr formation on stainless steel perforated sheets.

How to Determine If Burrs Are Within Normal Limits

Generally, slight burrs are acceptable, especially when they do not affect product functionality or safety. A common way to assess this is by touch: if you lightly run your fingers over the back of the stainless steel perforated sheet and feel minor protrusions—typically between 0.1mm and 0.2mm in height—these burrs are considered normal. However, if the burrs are excessively large or sharp enough to cut skin, that indicates an abnormal condition, possibly due to improper punching parameters or severe die wear.

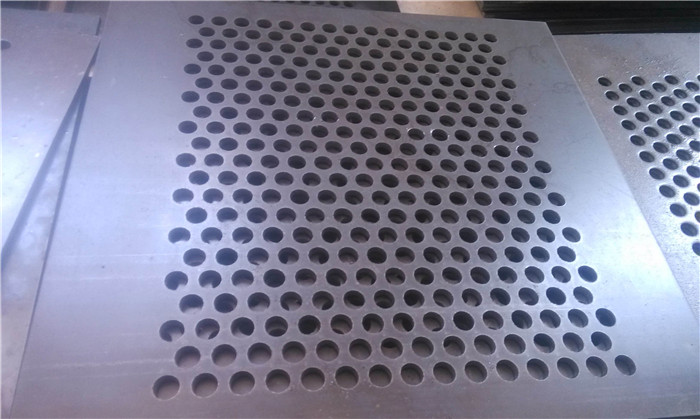

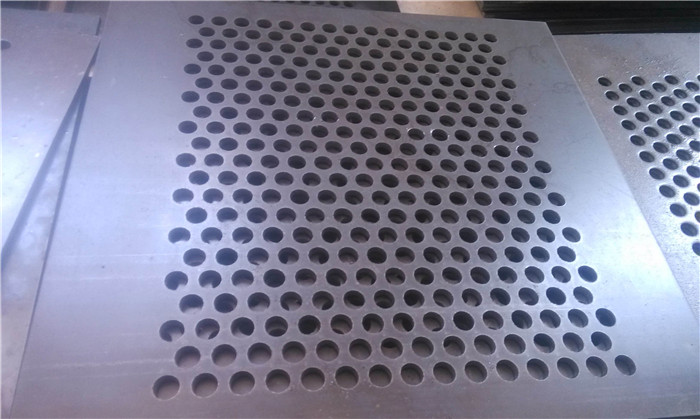

Stainless Steel Perforated Sheet

Methods to Control Burrs

To ensure product quality, manufacturers can adopt the following burr control measures:

Regular Die Inspection and Maintenance

Die wear is a major cause of increased burrs. Routine checks and timely regrinding or replacement can significantly reduce burr formation.

Optimize Punching Parameters

Adjusting punching speed and pressure to match the material properties can reduce tearing and thereby minimize burrs.

Post-Processing Deburring Techniques

For high-precision applications, adding deburring processes such as grinding, polishing, or chemical treatments can effectively remove burrs and enhance surface quality.

Choose Appropriate Materials

Different stainless steel grades respond differently during punching. Selecting the right material for perforation helps lower burr generation and improve overall sheet quality.

Conclusion

Slight burrs on the back of stainless steel perforated sheets are a natural byproduct of the punching process. As long as these burrs are within acceptable limits and do not compromise the product's functionality or safety, they are considered normal. However, excessive burrs can affect appearance, safety, and subsequent processing, so they must be addressed through proper burr control methods, die maintenance, and optimized manufacturing processes. For applications with strict quality requirements, communicating with your manufacturer to ensure compliance with specific standards is strongly recommended.