Common Materials for Aluminum Perforated Sheets

Source:www.cn-psp.cnAuthor:河北森驰公司 Last updated:2025-03-03 14:40:06 Browse:

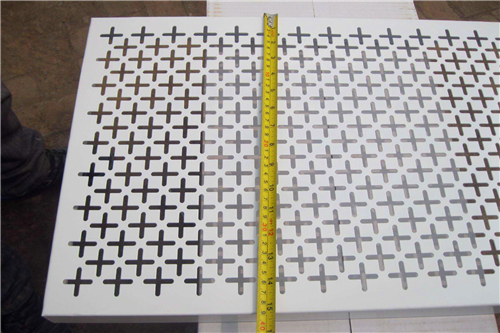

Aluminum Perforated Sheets are widely used in architecture, decoration, and acoustic engineering. Here are the typical material classifications and their characteristics:

1. Basic Aluminum Alloys

1xxx Series (Pure Aluminum):

Models: 1050, 1060.

Features: High purity (≥99.5%), excellent corrosion resistance but low strength. Suitable for indoor decoration or low-load applications (e.g., acoustic ceilings, wall designs).

3xxx Series (Aluminum-Manganese Alloys):

Models: 3003, 3004.

Features: Enhanced strength (tensile strength: 150–200 MPa) with manganese additives, ideal for outdoor façades or sunshades requiring wind resistance.

5xxx Series (Aluminum-Magnesium Alloys):

Models: 5052, 5083.

Features: High strength (tensile strength: 250–350 MPa) and seawater corrosion resistance, suitable for marine or industrial environments.

2. Special-Treated Materials

Anodized Aluminum:

Process: Electrochemical oxidation (10–25 μm thickness).

Advantages: Improved hardness (up to HV300) and wear resistance; customizable colors for architectural exteriors.

Powder-Coated Aluminum:

Process: Electrostatic spraying with high-temperature curing (60–120 μm thickness).

Advantages: UV resistance and diverse color options (RAL standards), ideal for long-term outdoor use (e.g., airport terminals).

Note: Consider load requirements (e.g., wind pressure), acoustic performance (NRC 0.4–0.8), and cost (5xxx series costs ~30–50% more than 1xxx). Finite element analysis is recommended for optimizing hole patterns and thickness.