Features and Applications of Perforated Aluminum Sheets

Source:www.cn-psp.cnAuthor:河北森驰公司 Last updated:2025-03-03 14:37:40 Browse:

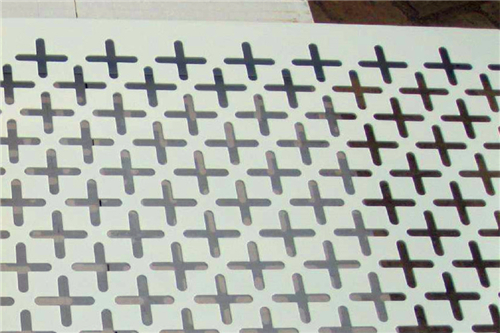

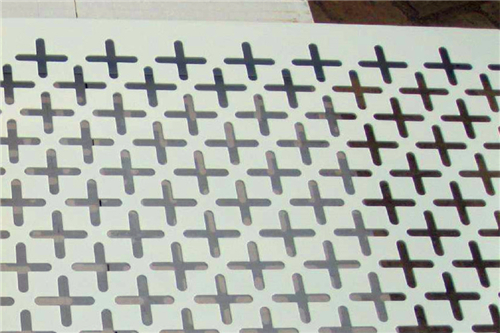

Perforated aluminum sheets are made by punching aluminum plates (typically with a thickness ranging from 0.5mm to 20mm) using specialized molds. These perforated sheets come in a wide variety of hole shapes, including round holes, oval holes, elongated round holes, square holes, rectangular holes, triangular holes, pentagon holes, hexagonal holes, octagonal holes, cross-shaped holes, plum blossom holes, diamond-shaped holes, fish-scale holes, louvered holes, round raised holes, crocodile mouth holes, and more. Custom hole shapes can also be made to order, and both hole size and spacing can be tailored to meet the specific needs of customers.

1. Lightweight, High Strength, and Excellent Corrosion Resistance

One of the most notable features of perforated aluminum sheets is their lightweight yet high-strength nature. Aluminum itself has excellent mechanical properties, particularly in terms of strength. Additionally, aluminum's natural resistance to corrosion makes perforated aluminum sheets suitable for use in humid, high-temperature, and variable environments. This makes them a popular choice for applications in building facades, signage, ventilation systems, and more. The aluminum surface naturally forms an oxide layer, which further enhances its corrosion resistance.

2. Good Malleability and Processing Performance

In addition to being lightweight and strong, perforated aluminum sheets offer excellent malleability. This means they can undergo a variety of surface treatments (such as spraying, anodizing, and polishing) to meet different aesthetic and functional requirements. The material is also easily cut, bent, and punched, making it versatile for different engineering needs.

3. Rich Surface Treatment Options

Perforated aluminum sheets offer great flexibility in surface treatment. Various spraying techniques, such as electrostatic powder coating, fluorocarbon coating, and painting, can be used. These treatments allow for a wide range of color effects, enhancing both the aesthetic appeal and functionality of the material. Sprayed aluminum sheets not only improve the visual appeal but also enhance their weather resistance and anti-pollution properties.

4. Anodizing and Polishing: Enhancing Durability and Aesthetics

Anodizing is a common surface treatment for perforated aluminum sheets, where an electrochemical reaction forms a thick oxide layer on the surface of the aluminum. This significantly improves the material's corrosion resistance and hardness. Anodized aluminum sheets also provide attractive decorative effects and are available in various colors to meet modern architectural and design requirements.

Polished perforated aluminum sheets have a smooth surface with high gloss. They are not only visually appealing but also easier to clean, making them suitable for environments that require a high level of cleanliness, such as medical, electronic, and food industries. Polished aluminum sheets also improve wear resistance and oxidation resistance, adding to their durability.

5. Excellent Filtration and Ventilation Properties

Due to the diverse hole shapes and the ability to customize hole sizes and spacing, perforated aluminum sheets exhibit excellent filtration and ventilation properties. These sheets are widely used in air purification systems, ventilation systems, and automotive exhaust systems, as they can facilitate airflow and gas filtration while preventing foreign objects from entering.

6. Environmentally Friendly and Sustainable

Aluminum is a recyclable material, which makes perforated aluminum sheets environmentally friendly. The recycling process saves a significant amount of energy, and the recycled aluminum retains much of its original physical properties. Therefore, perforated aluminum sheets not only have a long service life but also align with modern sustainable building and environmental protection practices.

7. Wide Range of Applications

Perforated aluminum sheets are widely used in various fields due to their excellent performance and versatile design. Some common applications include:

Architectural Decoration: Perforated aluminum sheets are commonly used for building facades, curtain walls, ceilings, and partitions. Their lightweight, aesthetic, and corrosion-resistant qualities make them a popular choice in modern architectural design.

Industrial Equipment: In industrial settings, perforated aluminum sheets are used in filters, heat exchangers, and ventilation equipment, meeting the requirements for efficient airflow and filtration.

Advertising and Signage: Due to their striking visual appeal, perforated aluminum sheets are widely used for advertising boards, display stands, and other promotional materials, helping to enhance brand image.

Transportation: Perforated aluminum sheets are also used in components of vehicles such as cars, trains, and airplanes, particularly in exhaust systems and ventilation systems, due to their light weight, durability, and corrosion resistance.

Conclusion

Perforated aluminum sheets are versatile materials that combine the advantages of being lightweight, strong, corrosion-resistant, and highly malleable. These sheets find wide application in architecture, industry, advertising, and other fields. With their diverse hole shapes, rich surface treatment options, and customization capabilities, perforated aluminum sheets not only meet functional requirements but also offer unique aesthetic appeal. As the demand for eco-friendly materials grows, the recyclability of aluminum makes perforated aluminum sheets a sustainable choice for modern construction and industrial applications.