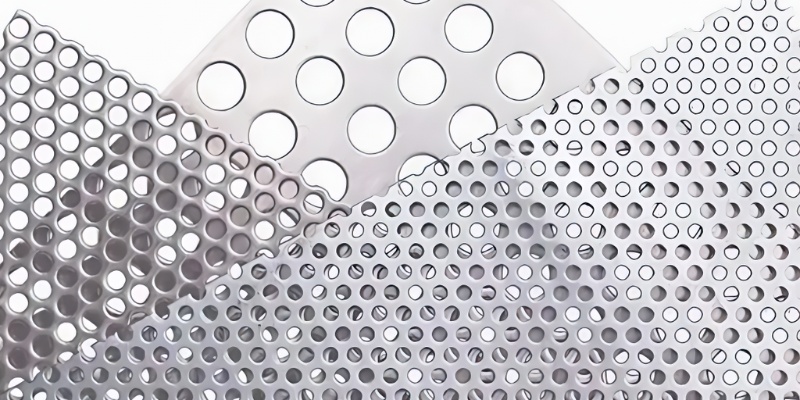

Hole diameter and open area ratio (percentage of open space) are key performance indicators that directly affect price.

Larger Hole Sizes

Reduce material usage and simplify production, making the mesh more affordable, though potentially at the expense of strength.

Smaller Hole Sizes / Higher Open Area Ratios

Require more complex processing and precision, increasing cost. However, they offer excellent airflow, light transmission, and filtration—sought after in industries like construction, decoration, and environmental engineering.

The right hole size should balance cost with functionality based on your project needs.

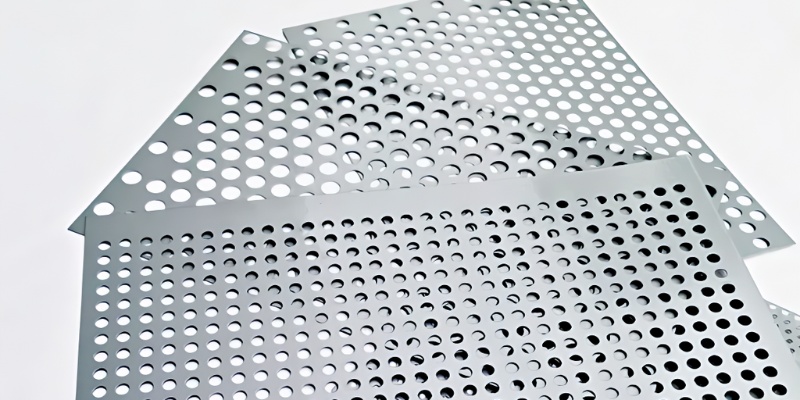

4. Manufacturing Process – Standard vs. Precision Production

Different manufacturing methods result in varying quality and cost.

Standard Perforation

Uses conventional punching machines for mass production. It is cost-effective and widely used in industrial and construction settings.

Precision Perforation

Utilizes advanced machinery to ensure strict tolerances and accurate spacing. Commonly applied in aerospace, medical devices, and high-end architectural elements. This method increases costs due to higher technical demands.

If your application requires high accuracy, precision perforation is a worthwhile investment.

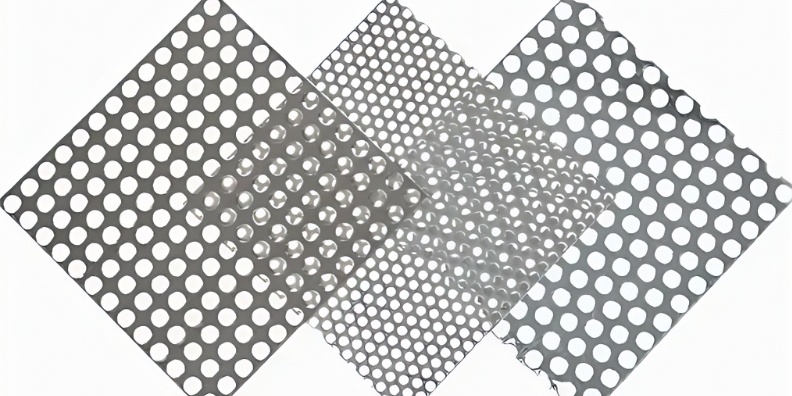

5. Customization – The More You Customize, The Higher the Price

Custom orders involving unique shapes, patterns, or finishes will increase the overall cost of perforated round hole mesh.

Non-Standard Hole Patterns

Shapes such as hexagons, diamonds, or fish-scale patterns require specialized tooling and complex programming, increasing production costs.

Surface Treatments

Options like powder coating, anti-rust plating, or brushed finishes enhance durability and aesthetics but come at an additional cost.

The more customization involved, the higher the final price.

6. Market Demand and Order Quantity – External Price Influencers

Supply and demand dynamics, as well as the size of your order, significantly affect pricing.

Bulk Purchases

Larger orders often come with volume discounts due to economies of scale, reducing cost per unit.

Market Fluctuations

High demand for specific types or specifications may lead to price surges. Conversely, when demand is low or supply exceeds demand, prices may drop.

Staying informed about market conditions and negotiating with suppliers can help you get better deals.

7. Transportation Costs – A Hidden Expense Not to Be Overlooked

As a metal product, perforated mesh can be heavy and bulky, making logistics a notable cost factor.

Long-Distance Shipping

Shipping across states or countries adds significant cost, especially for full-size sheets. The type of transportation (truck, sea, or air) also impacts expense.

Bulk Shipping Advantage

Consolidating orders into fewer shipments reduces per-unit transportation costs.

Consider sourcing from local suppliers whenever possible and consult with your provider for optimized shipping solutions.

Conclusion: Evaluate Needs, Control Costs Wisely

The pricing of perforated round hole mesh is influenced by multiple interrelated factors—from raw materials and sheet thickness to customization, manufacturing techniques, and market dynamics. For procurement professionals, a deep understanding of these elements allows for better cost control and smarter buying decisions.

If you need help selecting the right perforated round hole mesh for your application, feel free to contact our experienced team. We’re here to offer tailored solutions that meet your functional needs and budget expectations.