Specifications of Perforated Round Hole Sheets

Source:www.cn-psp.cnAuthor:河北森驰公司 Last updated:2025-03-08 14:38:03 Browse:

In industrial production and architectural decoration, perforated round hole sheets are widely used due to their unique performance and diverse designs. As a professional metal perforated sheet manufacturer, we provide you with a detailed introduction to the specifications and application features of perforated round hole sheets.

1. Hole Diameter: The hole diameter of perforated round hole sheets ranges from **0.2 mm to several hundred millimeters.

Minimum diameter (0.2 mm): Suitable for precision filtration devices.

Small to medium diameters: Commonly used for noise reduction, ventilation, and heat dissipation.

Larger diameters: Widely applied in decorative panels and acoustic absorption.

Custom sizes: Non-standard hole diameters can be customized as per specific requirements.

2. Sheet Thickness: Material thickness ranges from 0.1 mm to 30 mm.

Thin sheets (0.2–1 mm): Ideal for lightweight designs.

Medium thickness (1–5 mm): A balanced choice between strength and cost.

Thick sheets (5–30 mm): Offers excellent load-bearing capacity and durability.

Special specifications: Customization for ultra-thin or extra-thick sheets is available.

3. Hole Spacing: The spacing between holes directly affects grid density and transparency.

Standard spacing: Designed according to industry norms.

Custom spacing: Tailored to meet special engineering needs.

Calculation method: Optimal spacing can be determined based on application scenarios.

4. Material Types: A variety of materials are available.

Stainless steel: Offers the best corrosion resistance.

Aluminum alloy: Lightweight with good thermal conductivity.

Carbon steel: An economical and practical choice.

Other materials: Such as galvanized steel, titanium alloy, etc.

5. Sheet Dimensions: Various size specifications are available.

Standard sizes: 1m × 2m, 1.22m × 2.44m, etc.

Custom sizes: Cutting to specific dimensions based on customer requirements.

Maximum size: Limited by production equipment capacity.

Small-size processing: Available for precision instruments.

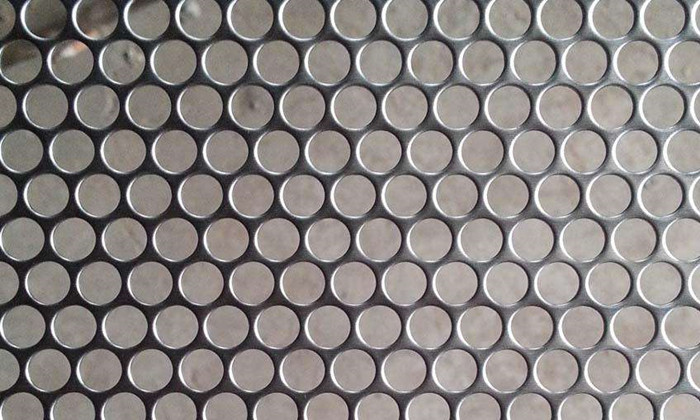

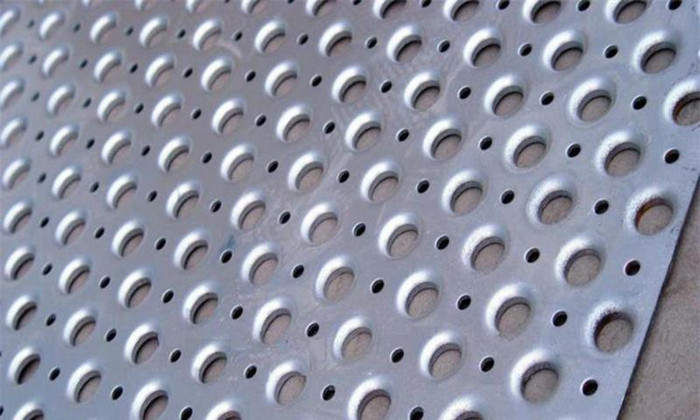

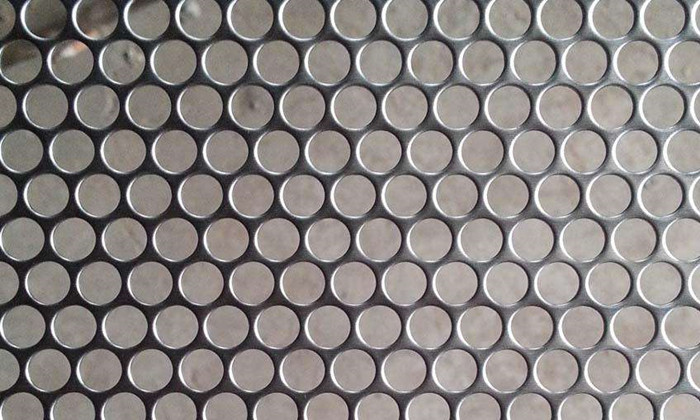

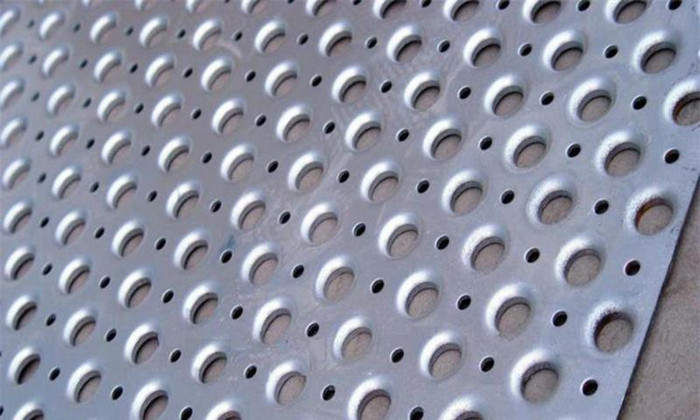

6. Hole Distribution Patterns: Common hole arrangements include.

Straight-line arrangement: Offers a clean and aesthetic look, often used in decorative panels and acoustic absorption.

Staggered arrangement: Enhances mechanical strength and is more widely applicable.

Other patterns: Concentric circle arrangements, irregular arrangements, etc.

7. Surface Treatment Options

Electroplating: Enhances corrosion resistance.

Spray coating: Improves appearance.

Polishing: Increases surface smoothness.

Anti-corrosion coating: Extends product lifespan.

8. Compliance with International Standards

GB/T national standards

ISO international standards

Industry-specific standards

9. Industry Applications

Perforated round hole sheets are used in multiple industries, including: Architectural decoration,Industrial filtration, Acoustic engineering, Mechanical equipment protection, etc.

10. Purchasing Recommendations

When selecting perforated round hole sheets, consider factors such as:

Application scenarios

Material properties

Budget constraints

After-sales service

This concludes the detailed introduction to the specifications of perforated round hole sheets. As a professional manufacturer, we offer customized solutions to meet specific customer needs. Feel free to contact us anytime!