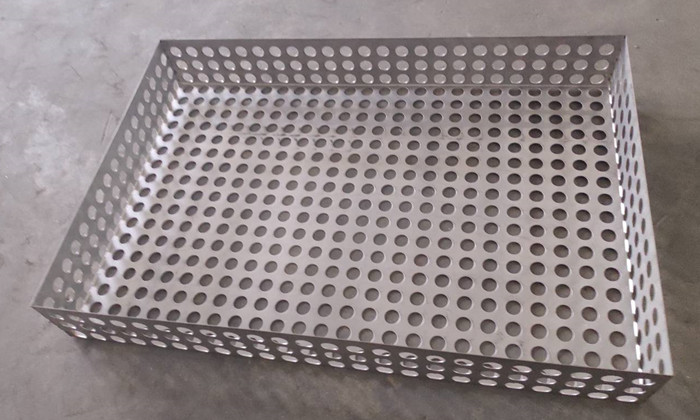

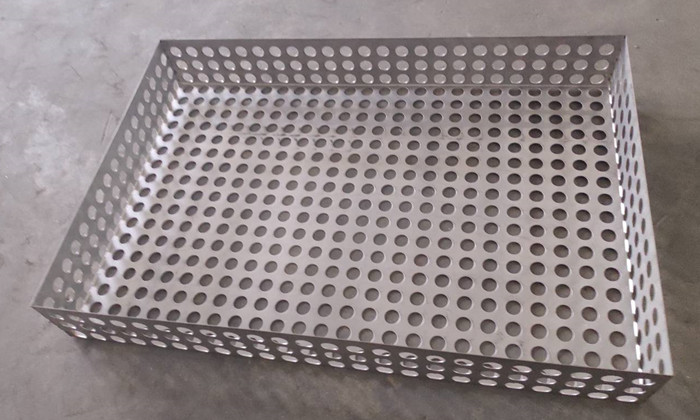

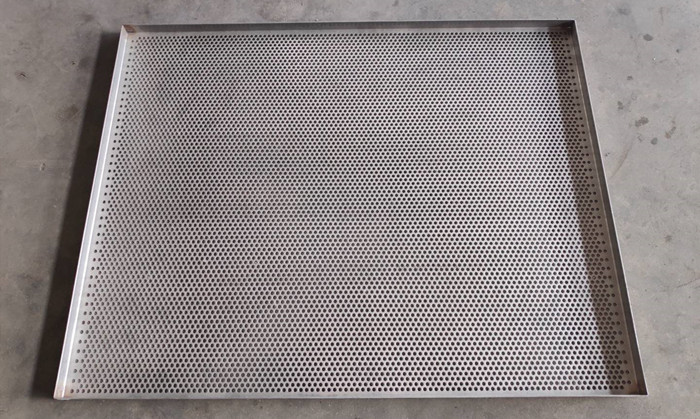

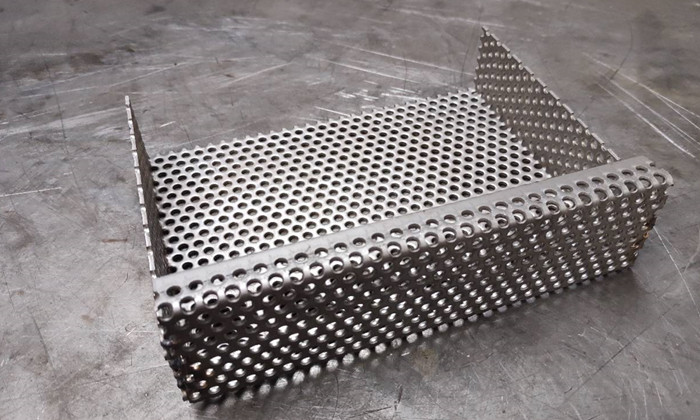

The Round Hole Perforated Drying Tray is a specialized drying accessory made from high-quality perforated plates. It is custom-manufactured based on customer requirements, offering more flexibility compared to standard trays available in the market. The trays can be customized in various sizes, heights, mesh patterns, hole diameters, material thicknesses, and materials to meet the specific needs of different industries. Whether for particular processes or specialized equipment, we provide tailored solutions to ensure optimal performance.

Our Round Hole Perforated Drying Trays are widely used in industries such as food processing, pharmaceuticals, chemicals, and electronics. They are ideal for applications involving drying, filtering, baking, and other processes. With their unique design and superior performance, they significantly enhance drying efficiency, reduce production time, and minimize maintenance costs.

Round Hole Perforated Drying Tray Specifications

Material Options:

We offer a variety of materials for the Round Hole Perforated Drying Tray to meet different environmental and operational needs. Common materials include:

Iron Plate: Ideal for standard drying applications, providing good load-bearing capacity at a cost-effective price.

Aluminum Plate: Lightweight, corrosion-resistant, and suitable for drying applications where weight is a concern.

Stainless Steel: Best suited for high-humidity, high-temperature, or corrosive environments. Stainless steel trays are durable, corrosion-resistant, and widely used in industries such as food processing and chemicals.

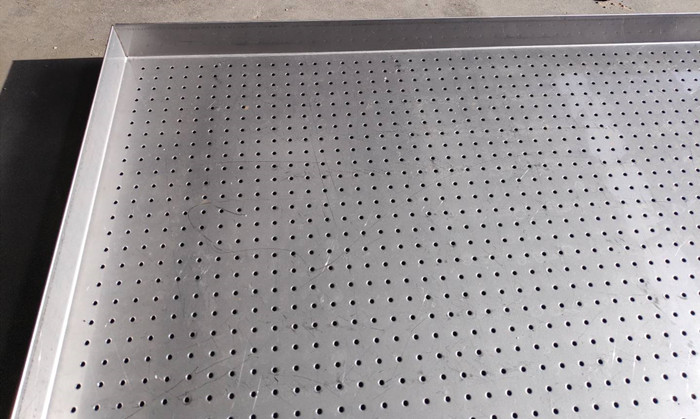

Thickness Customization:

The thickness of the Round Hole Perforated Drying Tray can be tailored to your specific requirements, with common thickness options ranging from 0.5mm to 3mm. Thicker trays are suitable for heavy-duty applications or harsh environments, while thinner ones are appropriate for light-duty drying tasks.

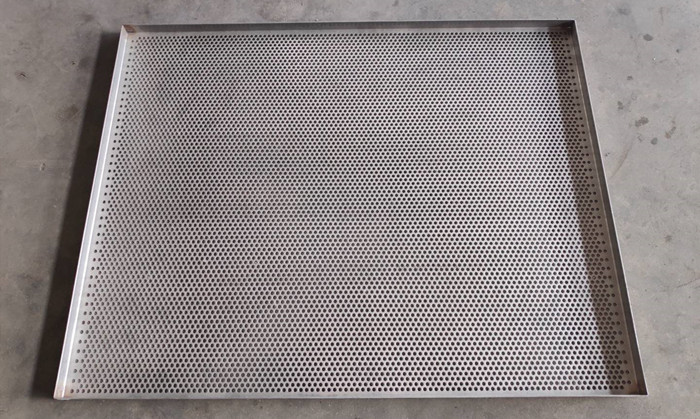

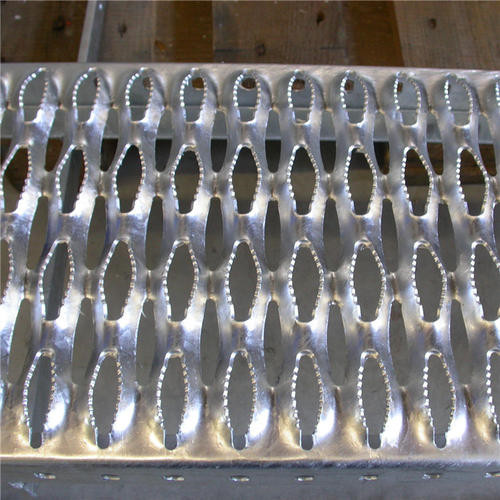

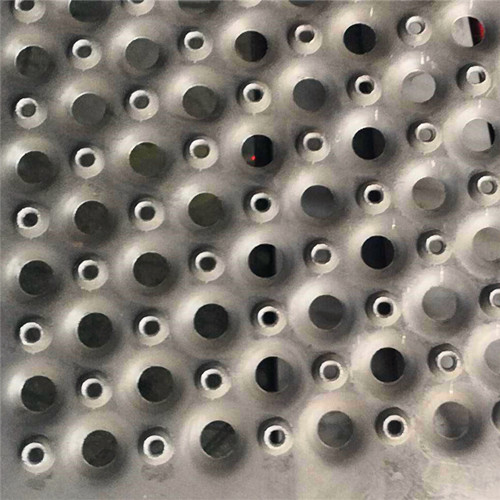

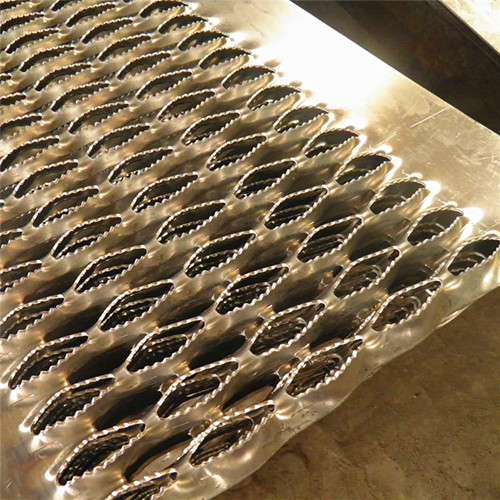

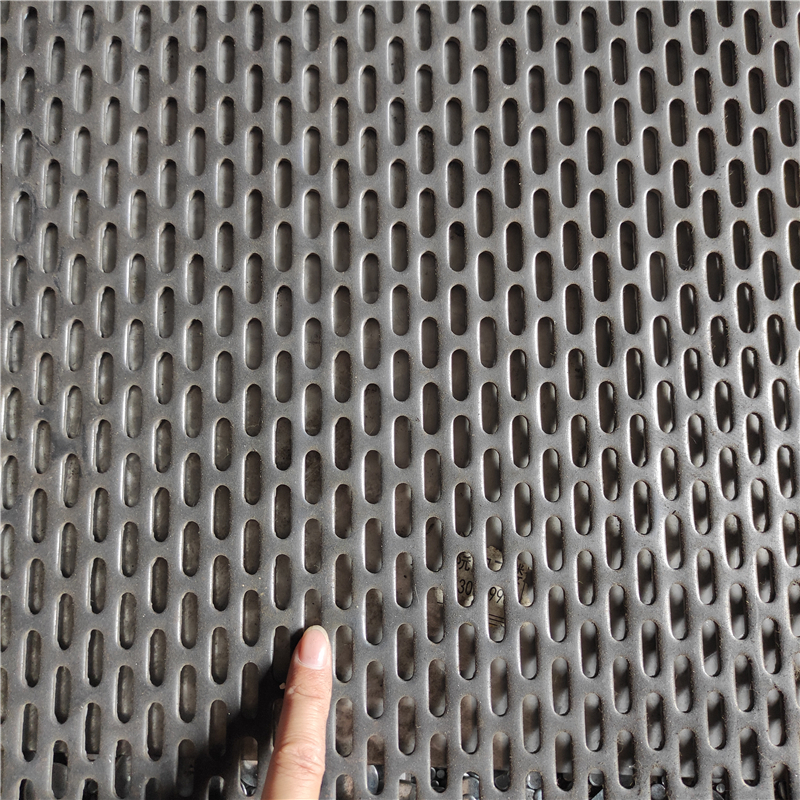

Hole Pattern Options:

The trays can be customized with various hole patterns to enhance airflow and drying efficiency. Some of the common hole patterns include:

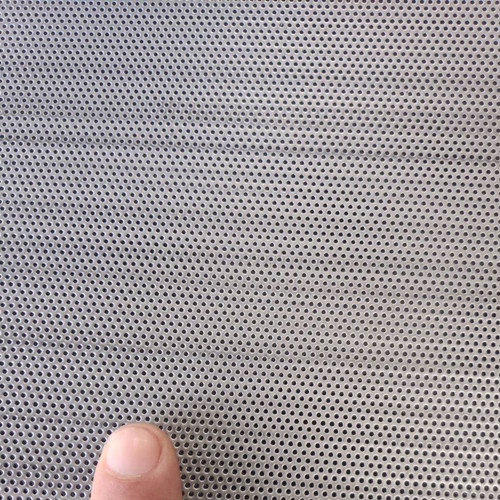

Round Holes: A versatile pattern that ensures smooth airflow and is suitable for most drying applications.

Oval Holes, Square Holes: Ideal for applications requiring specific airflow patterns or unique aesthetics.

Triangular Holes, Star-Shaped Holes, Hexagonal Holes: These specialized patterns can be customized for applications requiring unique fluid dynamics or appearance.

Zigzag Holes, Cross-Shaped Holes, Diamond-Shaped Holes: Custom-designed patterns to improve ventilation and airflow in specific drying processes.

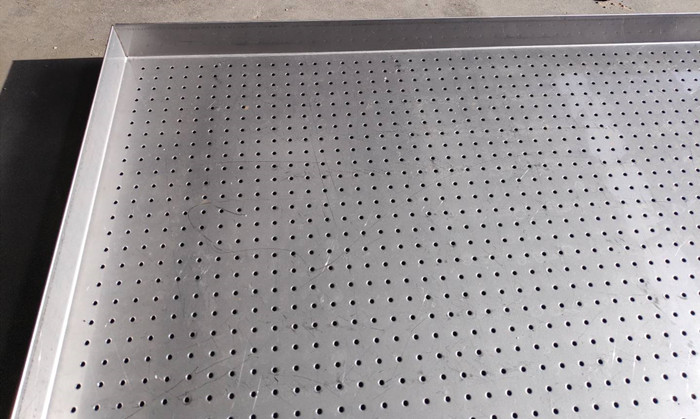

Hole Diameter and Spacing:

The diameter and spacing of the holes can be customized to match the needs of different materials and drying processes. Hole diameters typically range from 1mm to 30mm, and hole spacing and arrangement can be adjusted according to your specific requirements, ensuring optimal airflow and drying performance.

Advantages of Round Hole Perforated Drying Tray

High Customizability:

The Round Hole Perforated Drying Tray offers exceptional flexibility in customization. Users can adjust the tray's size, material, thickness, hole pattern, hole diameter, and spacing based on their production needs. This high degree of customization makes our trays ideal for various drying applications, providing flexibility and efficiency in your operations.

Enhanced Drying Efficiency:

The precise hole design of the tray improves airflow, ensuring that hot air circulates evenly across the tray surface and the materials being dried. This results in faster and more efficient drying. Whether in high-humidity or high-temperature environments, our trays maximize drying efficiency, saving both time and energy.

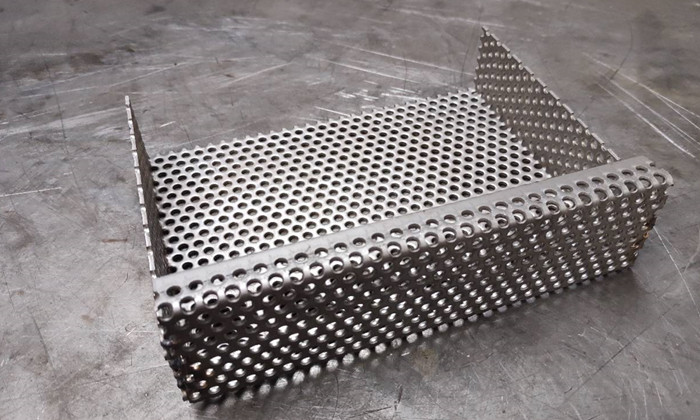

Durability and Longevity:

Made from high-quality materials, such as stainless steel and aluminum, our trays are designed to withstand harsh environments, including high temperatures, moisture, and chemical exposure. This makes them durable and long-lasting, reducing maintenance costs and ensuring reliable performance over time.

Minimized Post-Processing:

Many of our Round Hole Perforated Drying Trays are available in stock with standard specifications, allowing customers to use the trays directly without the need for secondary processing. This not only saves time but also reduces additional labor costs, allowing you to focus on your core production processes.

Cost Optimization:

The custom design of the trays ensures that you only pay for the features you need, helping to optimize production costs. By adjusting hole size and spacing to match the drying requirements, you can improve drying efficiency, reduce energy consumption, and lower overall production costs.

Round Hole Perforated Drying Tray Pricing

The price of the Round Hole Perforated Drying Tray is determined by its specifications and customization requirements. As each order may vary depending on material, size, hole pattern, and thickness, we recommend contacting us via email with your specific requirements. Our professional customer service team will provide you with a detailed quote based on your needs.

Why Choose Us?

As a leading manufacturer of Round Hole Perforated Drying Trays, we are committed to providing high-quality, customized solutions for our global customers. We offer not only standard trays but also tailor-made solutions for unique drying applications. Our advantages include:

Global Supply Chain Support: We have branches and partners in multiple countries, enabling us to provide timely delivery and excellent after-sales support worldwide.

Experienced Team: Our design and production team has years of experience in the field, allowing us to offer comprehensive solutions from design to production and after-sales service.

Quality Assurance and After-Sales Service: We provide complete after-sales support to ensure that your equipment continues to perform optimally throughout its life cycle.

Client Success Stories

We have provided Round Hole Perforated Drying Trays to many well-known international companies across industries such as food processing, pharmaceuticals, and chemicals. Our products have earned the trust and satisfaction of customers for their reliability, performance, and quality.