Common Hole Types and Hole Size Options for Perforated Metal Sheets

Source:www.cn-psp.cnAuthor:河北森驰公司 Last updated:2025-03-04 13:15:52 Browse:

In the production and application of perforated metal sheets, the selection of hole types and hole sizes is a critical factor. These parameters not only affect aesthetics but also directly impact the functionality and applicability of the product. Below is detailed content about common hole types and hole size options for perforated metal sheets:

1.Common Hole Types

Perforated metal sheets come in a variety of hole types, each with its own specific application scenarios and advantages. Here are some of the most common hole type classifications and their characteristics:

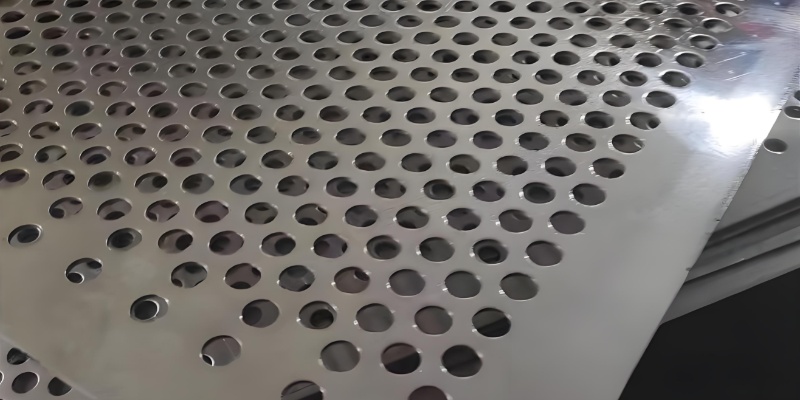

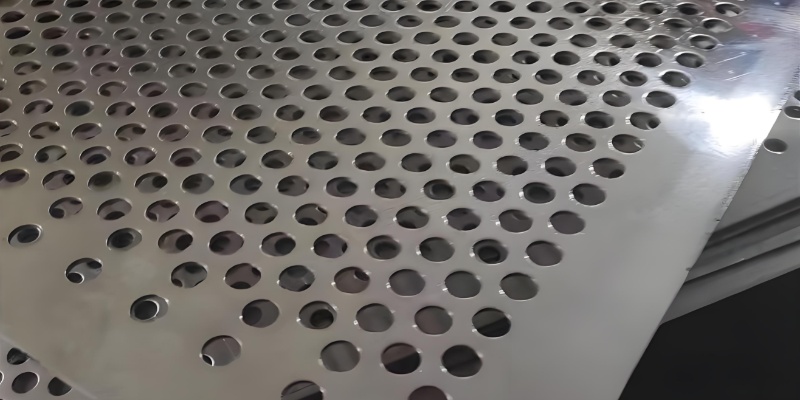

Round Holes

Round holes are the most classic and widely used hole type. They have the characteristic of uniform stress distribution and are suitable for filtration, ventilation, and decoration among other uses. The design of round holes is simple and easy to process, making them very popular in industrial and architectural fields. Additionally, round holes can achieve different visual effects by adjusting the spacing between holes; for example, closely arranged round holes can create a soft light scattering effect, while sparsely arranged ones are better suited for emphasizing structural feel.

Square Holes

Square holes are favored due to their regular geometric shape, especially in applications requiring precise arrangement. Square holes are commonly used in screening, filtration, and decorative panels. Compared to round holes, square holes can provide a larger open area while maintaining high strength and stability. This type of hole is often used in industrial equipment that requires a combination of high throughput and strength.

Rectangular Holes

Rectangular holes provide a larger open area and are often used in situations requiring high throughput, such as ventilation systems or acoustic barriers. Their unique shape can effectively reduce wind resistance and improve air circulation efficiency. The design flexibility of rectangular holes is also high, allowing adjustments to the length-to-width ratio based on actual needs to meet requirements for different application scenarios. For instance, in building design, rectangular holes can be used to make louvers, ensuring good ventilation while also having a certain decorative quality.

Triangular Holes

Triangular holes have strong structural stability and are suitable for environments needing to withstand higher pressure or impact forces. This type of hole performs exceptionally well in certain special industrial applications, such as manufacturing wear-resistant materials or protective covers, where triangular holes can significantly enhance the durability and impact resistance of products. Moreover, the unique shape of triangular holes also provides more creative space for designers, gradually gaining attention in artistic decoration.

Diamond-Shaped Holes

Diamond-shaped holes are uniquely designed, being both aesthetically pleasing and practical. They are often used in decorative panels and scenarios requiring a balance of strength and aesthetics. The symmetry of diamond-shaped holes makes them more visually appealing, while their structural features can also enhance the anti-deformation capability of the sheet to a certain extent. This type of hole is widely applied in high-end architectural decoration and exhibition displays.

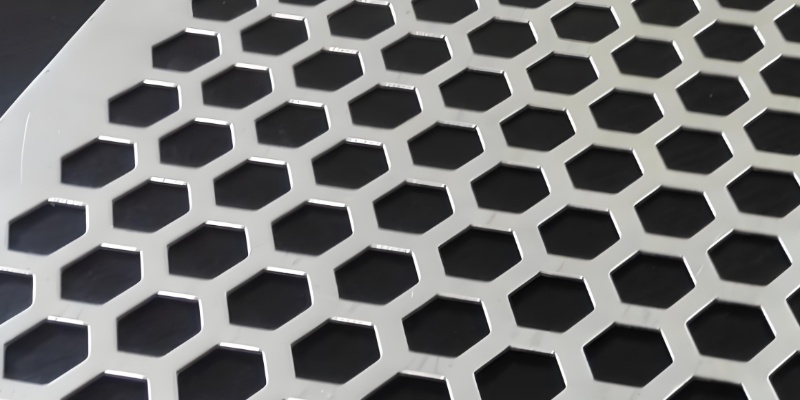

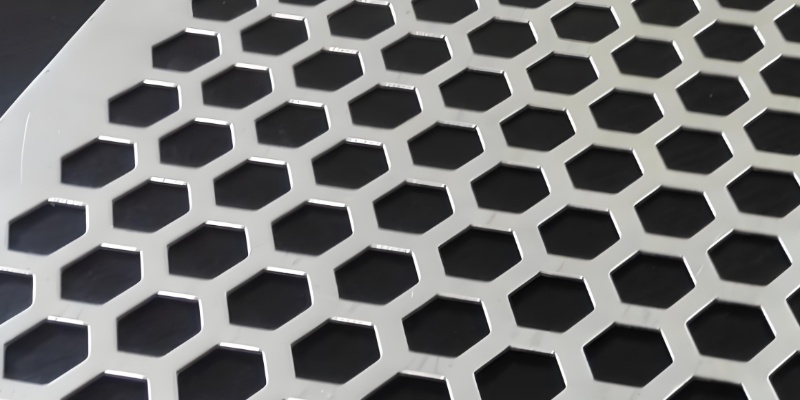

Hexagonal Holes (Honeycomb Style)

Hexagonal holes mimic the structure of natural honeycombs, possessing an extremely high strength-to-weight ratio. This type of hole is widely used in lightweight structural components and high-end decorative materials. The efficient use of space by hexagonal holes makes them ideal choices in aerospace, automotive manufacturing, and other fields. Additionally, the natural beauty of hexagonal holes also makes them highly regarded in modern architectural design.

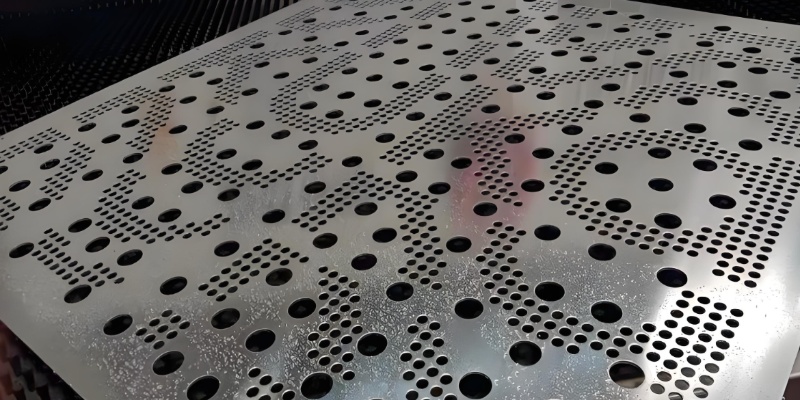

Irregular Holes

Irregular holes can be customized according to customer needs and are suitable for artistic decoration or special functional requirements. This flexibility allows perforated metal sheets to hold an important position in creative designs. Irregular holes can achieve personalized visual effects through complex pattern designs, such as abstract art patterns or brand logos, adding unique added value to the product.

2. Selection of Hole Sizes

The hole size refers to the dimension of the holes, usually expressed as diameter (for round holes) or other related parameters. The selection of hole size depends on specific application needs, and here are several key considerations:

Filtration and Screening

In filtration and screening applications, the hole size must be precisely controlled to ensure effective separation of particles. Smaller hole sizes are suitable for filtering fine particles, while larger ones are better for coarse particle screening. For example, in the food processing industry, using small-hole perforated metal sheets can effectively filter out impurities, ensuring product purity; whereas in mining, large-hole perforated metal sheets can quickly screen out larger ore particles.

Ventilation and Noise Reduction

For ventilation systems or acoustic barriers, the choice of hole size needs to balance air circulation with noise absorption performance. Generally speaking, larger hole sizes help increase airflow, but may reduce sound insulation performance; conversely, smaller hole sizes are better at reducing noise. In architectural design, reasonable hole size design can ensure good ventilation while effectively reducing external noise intrusion. For example, ventilation systems in subway stations often use medium-sized hole perforated metal sheets, which can meet ventilation needs while reducing noise interference.

Decoration and Aesthetics

In decorative applications, the selection of hole size depends more on visual effects. Smaller hole sizes can create a delicate and refined appearance, while larger ones bring a bolder and more modern design style. For example, in hotel lobbies or exhibition halls, using small-hole perforated metal sheets can create an elegant light shadow effect, enhancing the overall quality of the space; whereas in industrial plants, large-hole perforated metal sheets better fit their simple and practical design philosophy.

Load-Bearing and Strength

In situations that need to carry heavy loads or withstand external forces, hole sizes should not be too large to avoid weakening the overall strength of the sheet. At this point, reasonable design should be combined with actual load requirements. For example, when manufacturing mechanical equipment casings, it is necessary to choose appropriate hole sizes for perforated metal sheets to ensure protection of internal components while also meeting heat dissipation and ventilation needs.

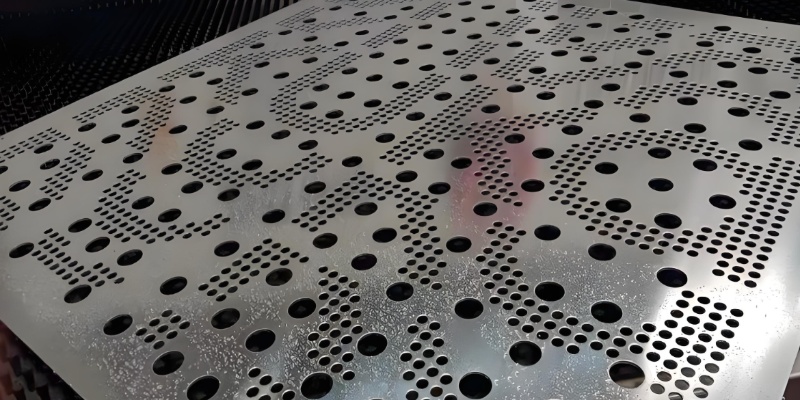

3. Combination Design of Hole Types and Hole Sizes

Besides considering hole types and hole sizes separately, different hole types and hole sizes can also be combined in design to achieve more diverse and multifunctional products. For example, combining round holes with rectangular holes can simultaneously realize filtration and ventilation functions on the same perforated metal sheet; combining hexagonal holes with diamond-shaped holes can enhance product decorativeness while ensuring strength. This method of combination design opens up broader prospects for the application of perforated metal sheets.

4. Summary

The selection of hole types and hole sizes for perforated metal sheets is a comprehensive consideration process involving functionality, aesthetics, and economy among multiple aspects. Whether it's the classic round holes or innovative irregular holes, different design schemes can meet various market demands. Through scientific selection, perforated metal sheets can play their unique value in various fields.