Differences Between Perforated Metal Sheets of Various Materials

Source:www.cn-psp.cnAuthor:河北森驰公司 Last updated:2025-03-03 13:50:34 Browse:

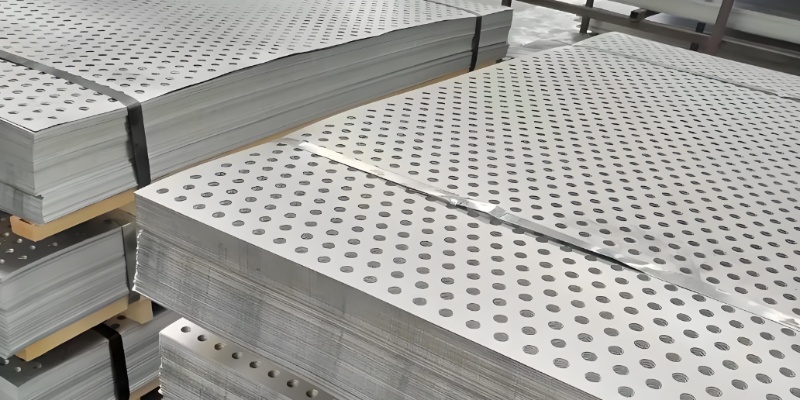

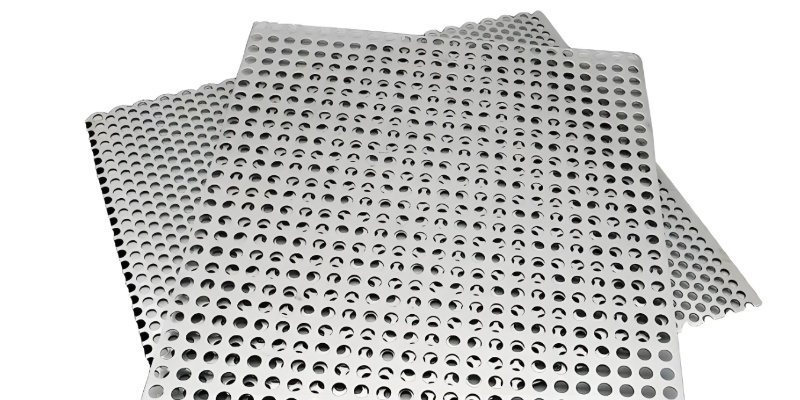

In modern industrial and architectural fields, perforated metal sheets are widely used due to their multifunctionality, aesthetics, and practicality. Perforated metal sheets made from different materials possess unique physical properties, chemical characteristics, and application scenarios. Below is a detailed comparative analysis of several common types of perforated metal sheets:

1. Stainless Steel Perforated Sheet

Corrosion Resistance: Stainless steel perforated sheets are renowned for their excellent corrosion resistance, primarily due to the dense chromium oxide protective layer formed on their surface. Even in humid or acidic environments, stainless steel can maintain good stability.

Strength and Hardness: Stainless steel has high mechanical strength and hardness, capable of maintaining its shape under significant pressure or impact. Depending on the alloy composition, stainless steel can be divided into different models such as 304, 316, each with slightly varying properties.

High-Temperature Performance: Some stainless steels (such as 310S) can maintain good oxidation resistance and structural stability at high temperatures, making them ideal for high-temperature equipment.

Application Areas: Food processing, pharmaceuticals, chemicals, medical devices, architectural decoration, etc. Especially in places requiring high cleanliness and hygiene standards, stainless steel perforated sheets are the preferred material.

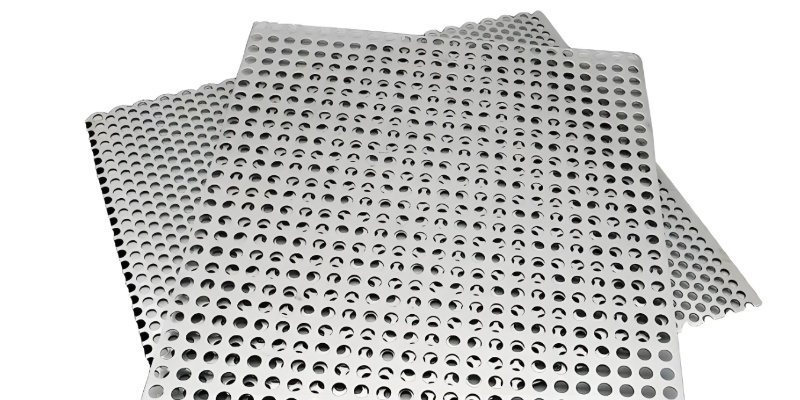

2.Aluminum Perforated Sheet

Lightweight: The biggest advantage of aluminum perforated sheets is their extremely low density, only about one-third that of steel. This characteristic makes it an ideal choice for reducing weight in transportation vehicles (such as cars, airplanes).

Corrosion Resistance: Aluminum naturally forms a dense layer of aluminum oxide when exposed to air, providing a certain level of corrosion resistance. However, in some strong acid or alkaline environments, aluminum may undergo chemical reactions.

Thermal and Electrical Conductivity: Aluminum has excellent thermal and electrical conductivity, suitable for heat exchangers, air conditioning systems, and other equipment requiring efficient heat conduction.

Malleability: Aluminum is easy to process into various complex shapes, making it suitable for architectural decoration, furniture manufacturing, etc.

Application Areas: Building facades, ceilings, air conditioning ventilation systems, electronic device housings, etc.

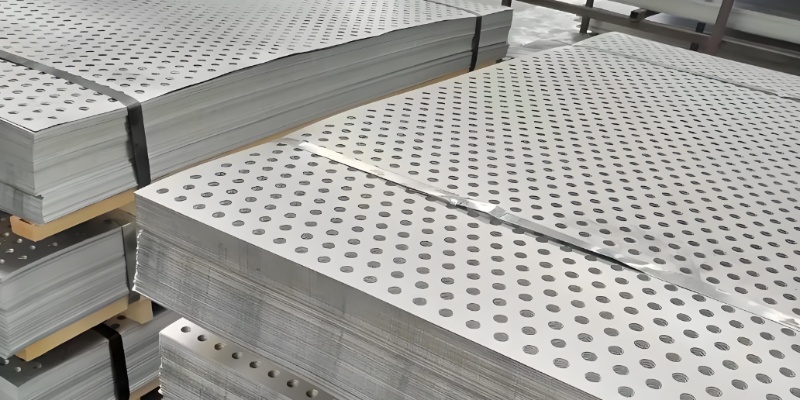

3. Galvanized Steel Perforated Sheet

Corrosion Resistance: Galvanized steel perforated sheets significantly enhance their corrosion resistance by plating a layer of zinc on the surface of ordinary steel plates. The zinc layer dissolves first when exposed to external erosion, protecting the base material from damage.

Cost-effectiveness: Compared to stainless steel, galvanized steel perforated sheets are more cost-effective, offering a highly economical choice.

Processing Performance: Galvanized steel has good processing performance and can undergo various processing methods such as stamping, bending, welding, etc.

Application Areas: Building facades, roofs, fences, ventilation ducts, agricultural facilities, etc.

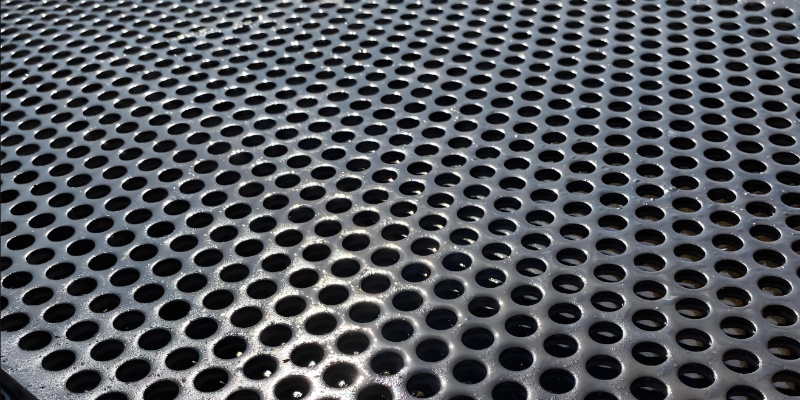

4. Carbon Steel Perforated Sheet

High Strength: Carbon steel perforated sheets have very high mechanical strength and toughness, capable of withstanding significant loads and impacts. Depending on the carbon content, carbon steel can be divided into low-carbon steel, medium-carbon steel, and high-carbon steel, each with different properties.

Price Advantage: Carbon steel perforated sheets are relatively inexpensive, making them an economically practical choice.

Prone to Rust: Untreated carbon steel is prone to oxidation and rusting in humid environments; therefore, rust prevention treatments such as painting or galvanizing are usually required before use.

Application Areas: Machine equipment protective covers, industrial filtration equipment, building structural components, etc.

5. Manganese Steel Perforated Sheet

Wear Resistance: Manganese steel perforated sheets are famous for their excellent wear resistance, particularly suitable for use in high-wear environments. The manganese element in manganese steel can significantly improve the material's wear resistance and impact resistance.

Toughness: Manganese steel maintains good toughness and ductility even at low temperatures, resisting brittle fractures.

Processing Performance: Manganese steel's processing performance is relatively poor, requiring special processing techniques to achieve ideal results.

Application Areas: Mineral processing equipment, concrete mixer liner plates, bulldozer bucket liners, crusher hammers, etc., in high-intensity wear environments.

6. Other Special Material Perforated Sheets

In addition to the above common materials, there are some special-purpose metal perforated sheets:

Copper Perforated Sheet: Has excellent electrical and thermal conductivity, commonly used in electrical equipment and radiators.

Titanium Perforated Sheet: Possesses extremely high strength and corrosion resistance, widely used in aerospace and marine engineering fields.

Composite Material Perforated Sheet: Made by combining two or more materials, possessing the advantages of each material, suitable for specific high-end applications.

Summary

Perforated metal sheets made from different materials each have their unique advantages and limitations. In practical applications, the most suitable material should be chosen based on specific usage environments, functional requirements, and budget factors comprehensively. For example:

- If high corrosion resistance is needed, stainless steel perforated sheets can be selected;

- If lightweight design is required, aluminum perforated sheets can be chosen;

- If cost-effectiveness is pursued, galvanized steel or carbon steel perforated sheets can be selected;

- If in a high-wear environment, manganese steel perforated sheets are the best choice.

By gaining a deep understanding of the characteristics of these different materials, you can better meet project needs, ensuring that product performance and service life reach optimal conditions.