Punching net brief introduction

Source:www.cn-psp.cnAuthor:河北森驰公司 Last updated:2025-03-04 13:13:39 Browse:

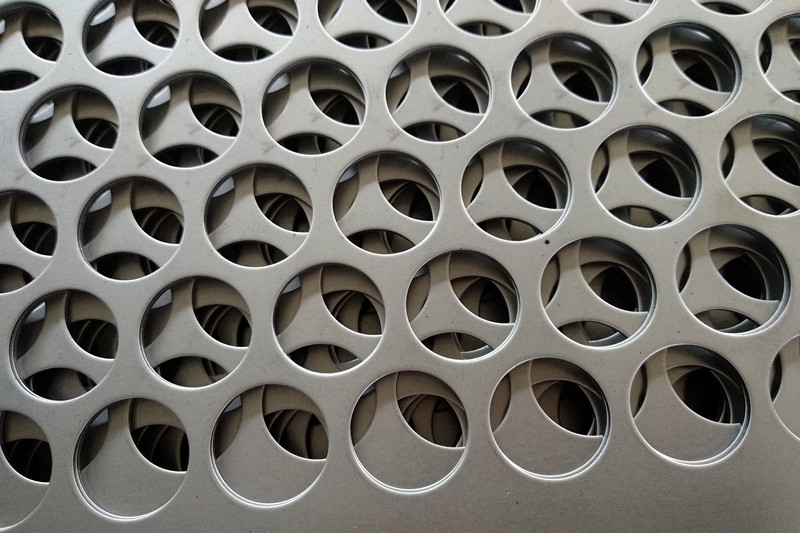

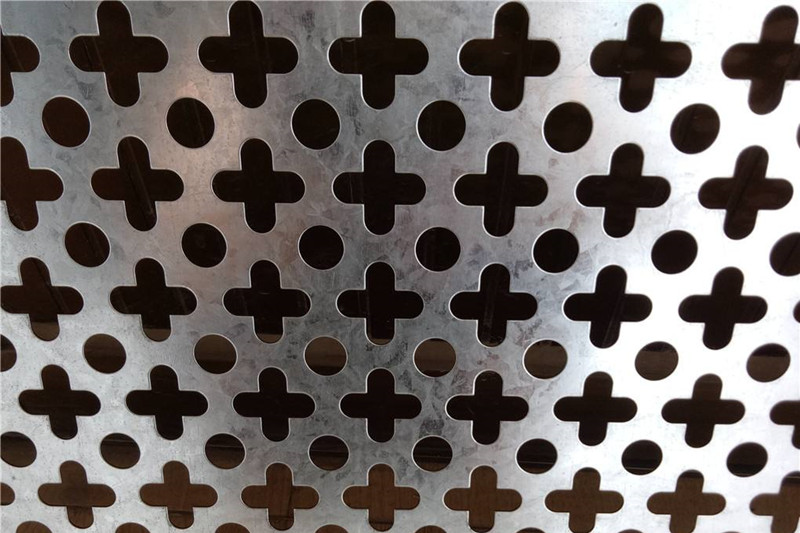

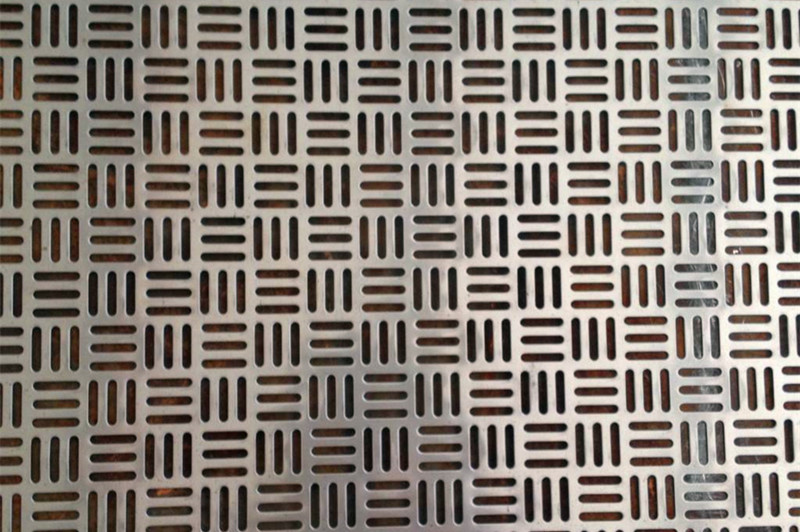

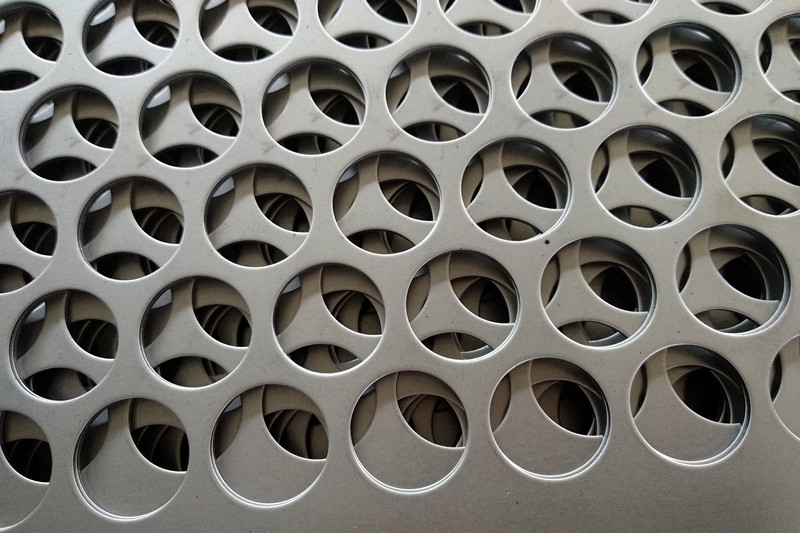

Punching net is also known as perforated plate, perforated sheet, steel plate perforation, etc. It is a process of punching various types of metal sheets with different thicknesses on a CNC punching machine to produce perforated plates with holes arranged in a certain pattern. The finished Punching net product has a smooth and flat surface, good corrosion resistance, and wear resistance.

Punching net

Punching net Specifications and Dimensions

Punching net Material: Different metal sheet materials can be used as raw materials.

Punching net Thickness: 1.0mm, 2.0mm, 3.0mm, etc. Various thicknesses are available, and other thicknesses of metal steel plates can be processed.

Punching net Requirements: The hole diameter can be from 1.0mm to 200mm, and the hole spacing can be processed according to the user's wishes. It can be selected. Special hole spacing can be processed according to the drawing.

Overall Size: 500*1000mm, 600*1000mm, 1000mm*2000mm, 1220*2440mm, etc. Other sizes of Punching net can be customized according to requirements.

Available Surface Treatment Methods: Powder coating, painting, polishing, etc.

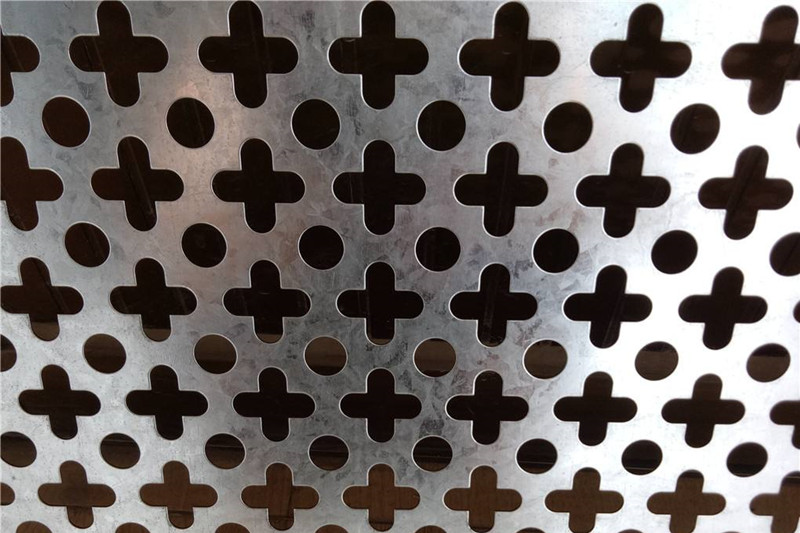

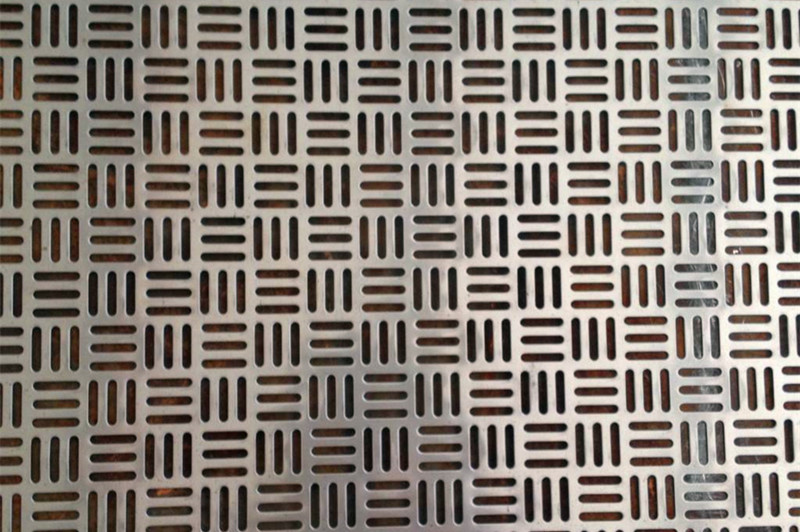

Manufacturer's Processable Hole Shapes: Common hole shapes processed include round holes, long rectangular holes, four-cornered holes, raised holes, five-cornered holes, oval holes, octagonal holes, round holes, fish-eye holes, combination-shaped holes, crocodile-mouth-shaped holes, irregular holes, slat-shaped holes, and peony-shaped holes.

Punching net

Punching net Classification

Punching net can be classified into iron plate perforated plate, galvanized perforated plate, stainless steel perforated plate, aluminum plate perforated plate, copper plate perforated plate, plastic perforated plate, etc., based on material;

Punching net can be classified into circular hole perforated plate, square hole perforated plate, long circular hole perforated plate, crocodile mouth perforated plate, lattice hole perforated plate, hexagonal hole perforated plate, fish eye hole perforated plate, pentagonal hole perforated plate, irregular hole perforated plate, etc., based on hole shape;

Punching net can be classified into thin plate perforated plate, medium plate perforated plate, thick plate perforated plate, extra thick plate perforated plate, based on plate thickness;

Punching net can be classified into laser perforated plate, CNC perforated plate, micro-perforated plate, anti-skid perforated plate, based on process;

Punching net can be classified into decorative perforated plate, perforated foot tread plate, perforated drainage plate, perforated filter mesh, sound-absorbing perforated plate, etc., based on use.

Punching net

Punching net Uses:

1. For architectural decorative panels.

2. For the protection of mechanical equipment.

3. For the manufacture of crafts.

4. For high-end speaker grilles.

5. For ventilation and heat dissipation of grain.

6. For screening in mines, chemical plants, and fruit and grain processing.

7. For filtering water, oil, and other substances.

8. For kitchen utensils.

9. For screening plates for mechanical equipment.

10. For road and factory protection barriers.

Punching net