What is Galvanized Perforated Sheet and How Does It Achieve Corrosion Resistance?

Source:www.cn-psp.cnAuthor:河北森驰公司 Last updated:2025-03-03 13:51:47 Browse:

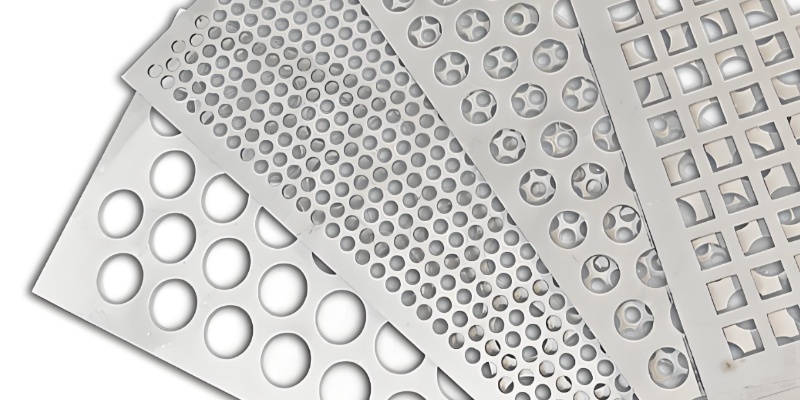

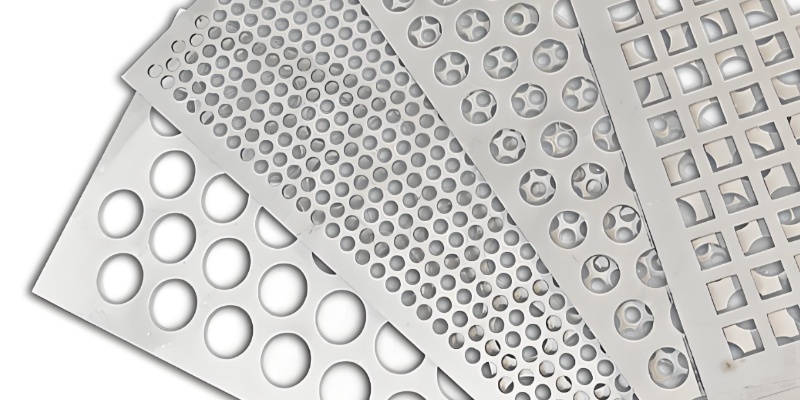

In the industrial and construction fields, galvanized perforated sheets are widely used materials. They are favored not only for their aesthetics and practicality but also because of their excellent corrosion resistance. This article will delve into the definition of galvanized perforated sheets and their principle of corrosion resistance.

1. Definition of Galvanized Perforated Sheet

A galvanized perforated sheet refers to a metal plate that undergoes galvanization on its surface and is then processed with perforations according to specific patterns or requirements. This type of plate combines the corrosion-resistant characteristics of the galvanized layer with the functionality of the perforated structure, finding wide application in architectural decoration, acoustic treatment, machinery equipment, and other fields.

Galvanization: Galvanization is a metal surface treatment technology where steel products are immersed in molten zinc to form a protective zinc layer on their surface, thereby enhancing the corrosion resistance of the steel.

Perforation: According to design requirements, holes of various shapes and sizes are punched into the steel plate. These holes can be used for ventilation, sound insulation, filtration, and other purposes.

2. Corrosion Resistance Principle of Galvanized Perforated Sheets

The reason why galvanized perforated sheets can effectively resist corrosion mainly lies in the following aspects:

Sacrificial Anode Protection of Zinc Layer: Zinc has higher electrochemical activity than iron (steel). When the galvanized layer is exposed to a corrosive environment, zinc will preferentially undergo an oxidation reaction, thereby protecting the underlying steel from corrosion. This phenomenon is called "sacrificial anode protection."

Physical Barrier Role of Zinc Layer: The zinc layer itself also serves as a physical barrier, preventing oxygen and water from directly contacting the surface of the steel plate, thus reducing the occurrence of corrosion.

Self-repairing Capability of Zinc Layer: Zinc forms a dense zinc oxide film in the air, which further prevents the intrusion of corrosive media. Moreover, under minor damage conditions, a new oxide film will reform, providing continuous protection.

3. Application Scenarios

Due to its unique properties, galvanized perforated sheets have extensive applications in multiple fields:

Architectural Decoration: Used for exterior wall decoration, ceilings, partitions, etc., combining aesthetics with functionality.

Acoustic Treatment: Utilizing the perforated structure to absorb noise and improve the indoor acoustic environment.

Machinery Equipment: Used to manufacture equipment housings requiring good ventilation and corrosion resistance.

Conclusion

With its superior corrosion resistance and multifunctionality, the galvanized perforated sheet has become an ideal choice in modern industry and construction fields. By understanding its definition and corrosion resistance principle, we can better utilize this material to meet the needs of different application scenarios.