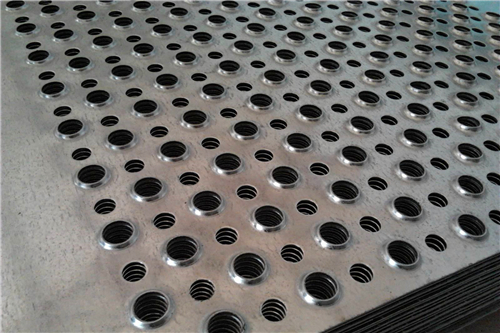

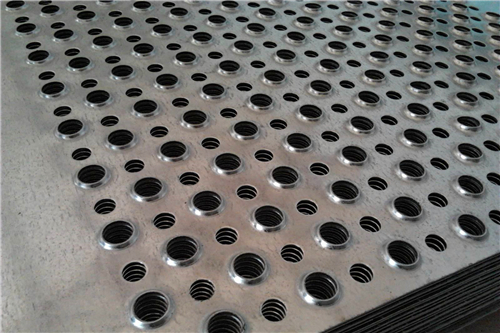

Aluminum Perforated Plate Processing Methods

Source:www.cn-psp.cnAuthor:河北森驰公司 Last updated:2025-03-03 13:53:00 Browse:

Aluminum perforated plates are metal sheets made by perforating aluminum plates at specific intervals and hole patterns. The production process typically involves multiple processing techniques, allowing customization of various shapes and sizes based on customer requirements. These plates are widely used in fields such as construction, decoration, furniture, industry, and machinery. Below are some common processing methods for aluminum perforated plates:

1. CNC Punching Machine Processing

A CNC punching machine is a high-efficiency metal processing tool that uses computer programs to precisely punch holes into aluminum plates according to preset patterns and hole spacing. This method is suitable for mass production, as it can quickly and accurately create perforated aluminum plates with specific hole diameters and patterns. The advantage of CNC punching is its high precision, high efficiency, and the ability to adjust punching parameters based on different aluminum plate thicknesses, meeting various production needs.

2. Cutting

Once the aluminum perforated plates are produced, they often need to be cut into different shapes and sizes according to customer requirements. Cutting is usually done using a CNC shearing machine, which can precisely cut the aluminum plates to the required dimensions. Common cutting shapes include rectangles, squares, triangles, and trapezoids. The cut aluminum plates can then undergo further processing, such as laser cutting or bending.

3. Laser Cutting

Laser cutting is another common method for processing aluminum plates. It uses a high-power laser beam to precisely cut aluminum plates, allowing for complex shapes to be created according to customer requirements. Compared to traditional mechanical cutting, laser cutting offers advantages such as high precision, minimal heat-affected zones, and smooth edges, making it ideal for producing intricate patterns. Laser cutting is widely used for custom designs, signage, and artistic decorations.

4. Bending

Bending is a common process in aluminum perforated plate fabrication, typically done using a CNC bending machine. The aluminum plate is bent at a specific angle using mechanical force, resulting in various curved shapes. Bending is often used for producing decorative or functional components, such as aluminum alloy window frames and decorative panels. The advantage of bending is that it allows the shape of the aluminum plate to be altered without changing its basic properties, meeting different design requirements.

5. Coiling

The coiling process involves rolling aluminum plates into cylindrical or tubular shapes, which is commonly used for applications such as chimneys, ventilation ducts, and air conditioning systems. This method is suitable for thin aluminum plates that need to be bent into specific shapes. Coiling provides a unique appearance for aluminum perforated plates while also enhancing their structural strength.

6. Welding

In many applications, aluminum perforated plates may need to be joined with other metal components. Welding techniques are often used to connect aluminum perforated plates to other parts. Methods such as TIG (Tungsten Inert Gas) welding or MIG (Metal Inert Gas) welding are used to ensure strong and durable connections. Welding not only increases the structural stability but also provides a seamless and aesthetically pleasing finish.

7. Surface Treatment

In addition to the primary processing methods mentioned above, surface treatment of aluminum perforated plates is equally important. Common surface treatments include anodizing, electroplating, and spraying. These processes improve the corrosion resistance, oxidation resistance, and aesthetic appearance of the aluminum plate. Different surface treatment methods can meet various customer needs for both performance and aesthetics.

Conclusion

The processing methods for aluminum perforated plates are diverse, with each method offering unique advantages for different production needs. By selecting the appropriate processing technique based on customer requirements, manufacturers can improve production efficiency while ensuring the quality of the final product. In modern industry, aluminum perforated plates are widely used across various sectors due to their excellent workability, durability, and visual appeal. Understanding and mastering the different processing methods can help customers make more informed decisions when choosing the right aluminum perforated plates for their applications.