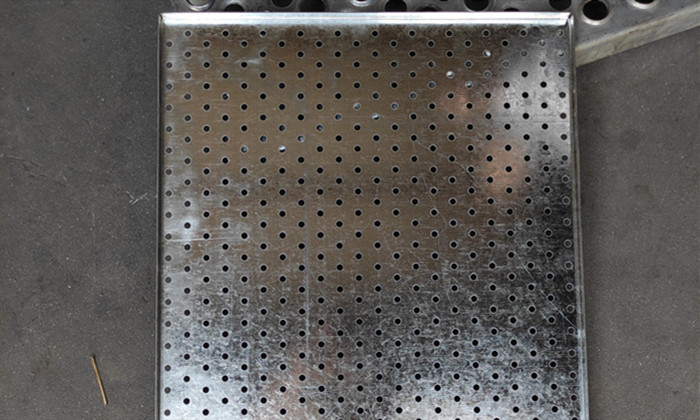

We are a professional perforated tray manufacturer from China, dedicated to providing high-quality custom perforated trays for global customers. Our products use high-quality perforated plates as raw materials and are processed with advanced production technology to offer highly flexible customization services. Compared with traditional pallets, our perforated trays offer significant advantages in terms of functionality, load-bearing capacity, ventilation, and breathability, making them widely used in warehousing, logistics, industrial manufacturing, food processing, and many other fields.

Specifications and Customization

Our perforated trays can be fully customized according to customer needs to ensure that each tray meets your specific application requirements. Customization options include:

Material Choices: We offer perforated trays made from a variety of materials, including:

Iron Plate Perforated Tray: Suitable for general environments, economical and practical.

Aluminum Plate Perforated Tray: Lightweight with excellent corrosion resistance, ideal for chemical storage.

Stainless Steel Perforated Tray: Suitable for high-demand environments, offering high temperature and corrosion resistance, widely used in food, pharmaceutical, and other industries.

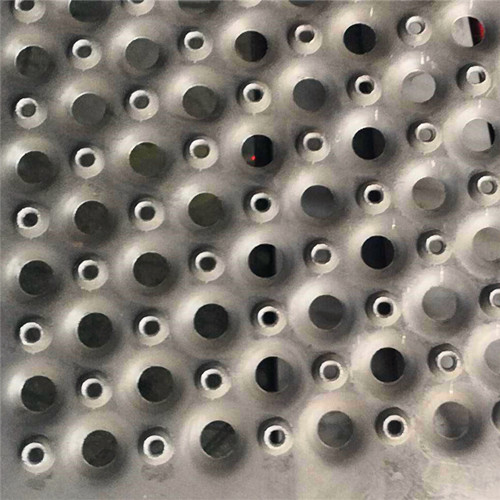

Thickness Customization: The thickness of the perforated tray can be customized according to the load-bearing needs, generally ranging from 0.5mm to 3mm, suitable for light to heavy-duty storage.

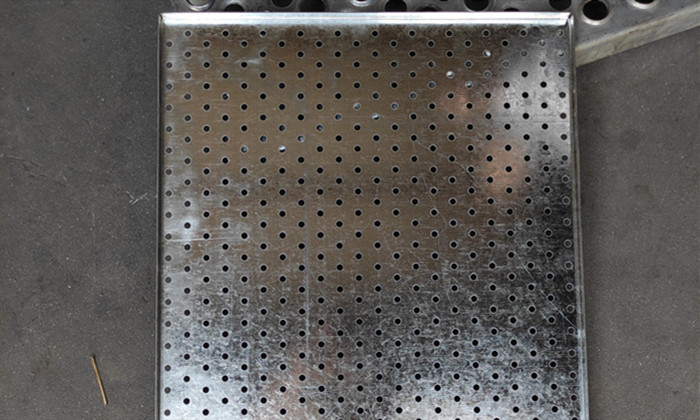

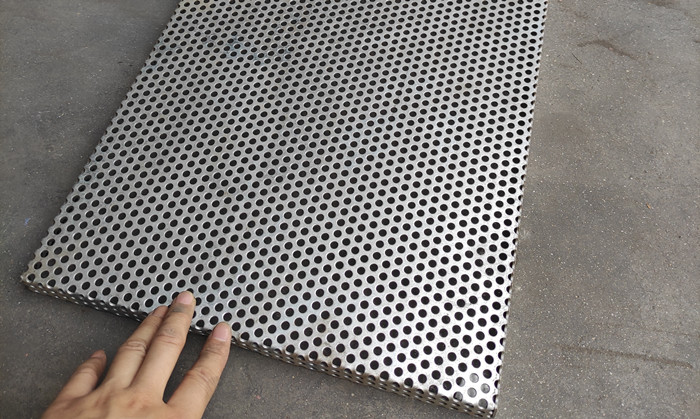

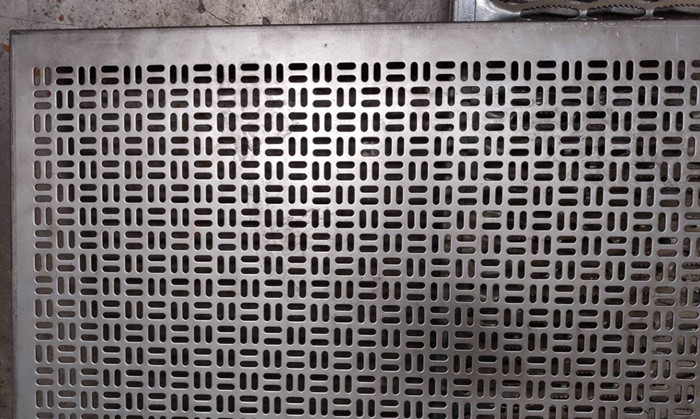

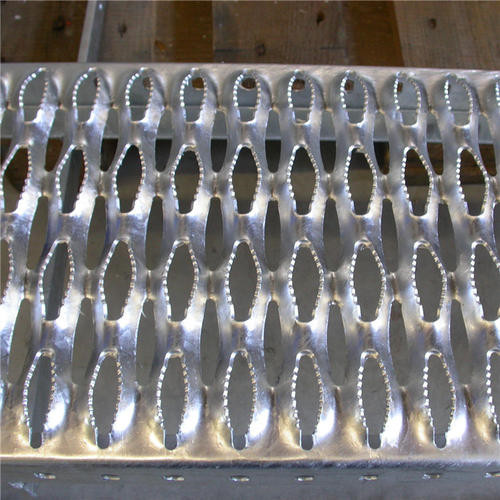

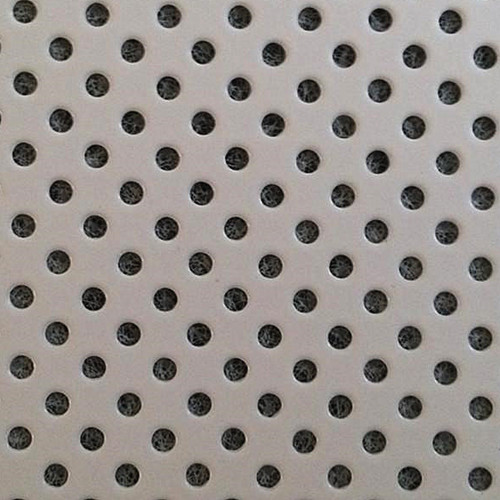

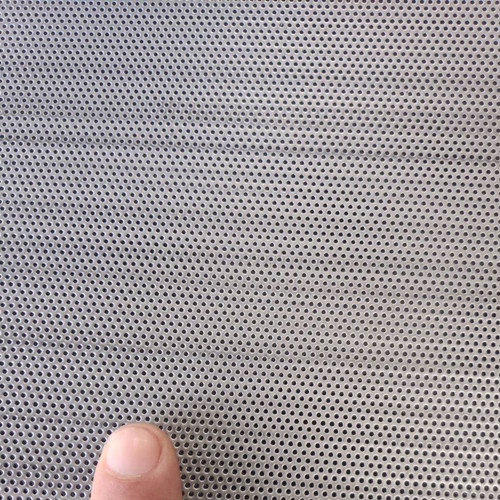

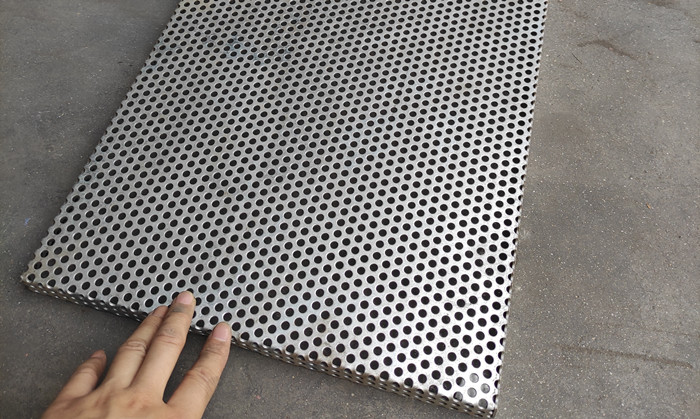

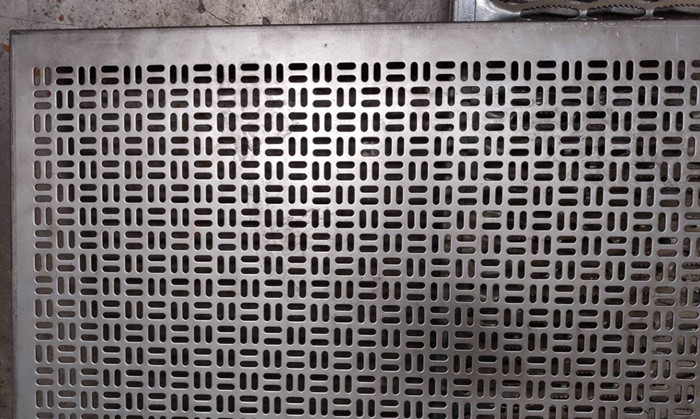

Hole Type and Size: We provide various hole types and sizes to meet your requirements. Common hole types include:

Round holes, oval holes, square holes, triangular holes, five-pointed star holes, hexagonal holes, eight-figure holes, cross holes, zigzag holes, H-shaped holes, diamond-shaped holes, etc.

The hole size can be customized according to needs, generally ranging from 1mm to 30mm, with adjustable hole spacing and arrangement.

Custom Features: We also offer customization for hole spacing and arrangement, providing the best ventilation or anti-slip design to ensure the tray’s performance.

Advantages of Perforated Trays

High Load-Bearing Capacity: Our trays are made from high-quality steel plates, stainless steel, or aluminum plates, ensuring strong load-bearing capacity. Whether for heavy-duty items or long-term use, they maintain stability and durability.

Corrosion Resistance: Through surface coating treatment, our perforated trays have excellent corrosion resistance, making them ideal for use in damp or chemical environments.

Excellent Ventilation: The perforated design allows air to circulate freely, effectively preventing items from getting damp, moldy, or deteriorating. This feature is especially useful in the food, pharmaceutical, and other industries with strict storage conditions.

Aesthetic and Durability: In addition to their functionality, our perforated trays also have an attractive appearance, with smooth surfaces and even coloring, making them suitable for modern warehousing environments. They also have a long service life, reducing the need for frequent replacements.

Customizable Design: We understand that every customer has unique requirements, which is why we offer fully customized services. Whether it's the size, thickness, material, hole type, or hole spacing, we can tailor the tray to perfectly meet your needs.

Environmental Friendliness and Recyclability: Our perforated trays are lightweight and recyclable, meeting green environmental standards and helping reduce resource waste, in line with sustainable development trends.

Wide Applications of Perforated Trays

Our perforated trays are widely used in various industries, offering exceptional versatility. Here are some of the main application areas:

Warehousing and Logistics: The ventilation and breathability of perforated trays help maintain the dryness of stored items, reducing moisture-related issues. They are suitable for bulk storage and transportation, improving space utilization in warehouses.

Food Industry: In food storage, the perforated design helps maintain air circulation, preventing spoilage and ensuring compliance with hygiene and safety standards.

Chemical Industry: Perforated trays are resistant to chemical corrosion, making them ideal for storing and transporting chemical products, particularly corrosive raw materials.

Pharmaceutical Industry: The ventilation of perforated trays ensures a dry storage environment, preventing pharmaceutical products from degrading, and complying with industry standards and hygiene requirements.

Electronics Industry: Perforated trays are lightweight and feature anti-static designs, making them suitable for storing and transporting electronic components, reducing the risk of moisture damage and static discharge.

Pricing of Perforated Trays

The price of perforated trays is calculated comprehensively based on specifications, materials, and customization options. Different specifications and models may result in different prices. If you have specific requirements, feel free to contact our professional customer service team, and we will provide a precise quote based on your needs.

Contact Information

If you have any inquiries or require more detailed information about our perforated trays, please contact us via email at: 342096438@qq.com.