Service Life of Galvanized Perforated Sheets

Source:www.cn-psp.cnAuthor:河北森驰公司 Last updated:2025-04-11 10:36:29 Browse:

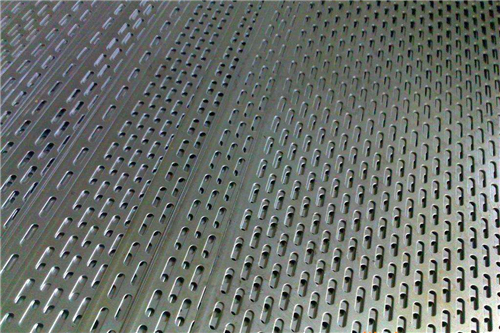

Galvanized perforated sheets, known for their excellent corrosion resistance, are widely used in construction, decoration, and industrial fields. Made from galvanized steel sheets processed by a CNC punching machine, these sheets have a zinc coating on the surface. This zinc layer not only effectively prevents oxygen and moisture from directly contacting the steel sheet but also protects it from corrosion caused by acidic, alkaline, or atmospheric pollution. As a result, galvanized perforated sheets have a much longer service life than regular steel perforated sheets, typically lasting more than 20 times longer.

Factors Affecting the Service Life of Galvanized Perforated Sheets

The service life of galvanized perforated sheets is influenced by several factors, including:

Zinc Layer Thickness: The thickness of the zinc layer directly impacts the corrosion resistance of the perforated sheet. The thicker the zinc layer, the longer the protection lasts, resulting in a longer service life.

Environmental Conditions: Prolonged exposure to humid or corrosive environments can reduce the effectiveness of the zinc layer's protection, shortening the service life of the galvanized perforated sheet.

Mechanical Wear: In high-friction or impact-prone environments, the zinc layer may suffer damage or wear, exposing the steel underneath and shortening its lifespan.

Regular Maintenance: While the zinc layer provides strong corrosion resistance, regular inspections and cleaning can prevent damage to the zinc coating and further extend the service life of the galvanized perforated sheet.

Recommendations for Extending Service Life

To ensure the long-term use of galvanized perforated sheets, the following measures are recommended:

Avoid direct contact with corrosive chemicals.

Regularly clean the surface to remove dirt and moisture, maintaining the integrity of the zinc layer.

Add protective measures in areas prone to wear and tear to reduce mechanical damage.

Ensure proper installation to avoid surface damage and compromising the protective zinc layer.

By following these simple maintenance practices, galvanized perforated sheets can be reliably used in various harsh environments, extending their service life.