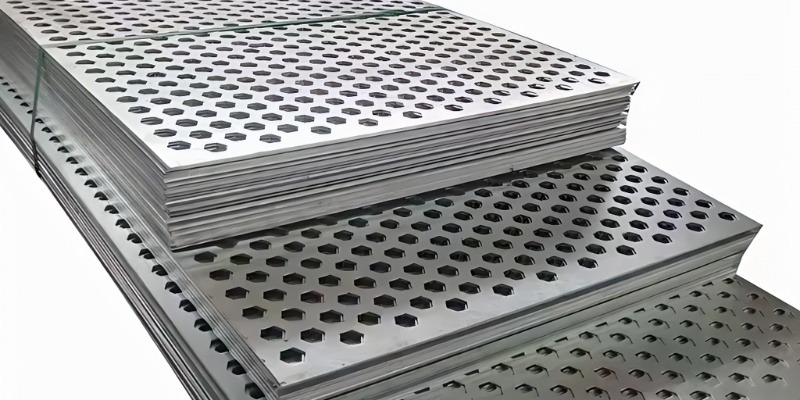

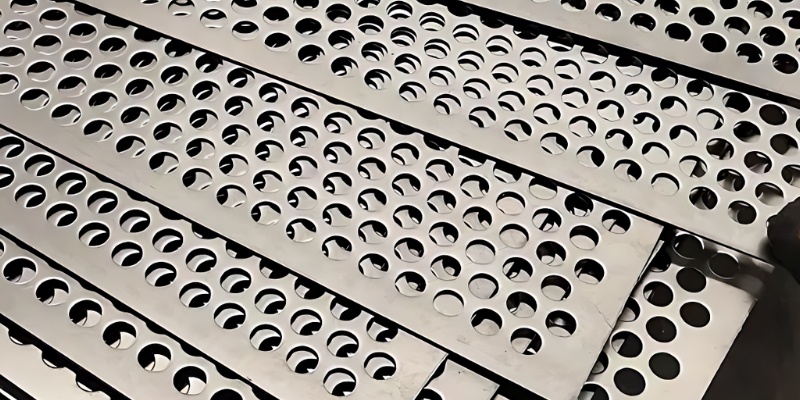

Diverse Perforation Patterns

Perforated aluminum sheets come in a wide variety of hole designs, allowing users to choose the most suitable style for their specific needs. The common perforation patterns include:

Round Holes, Oval Holes, and Slotted Holes (Ideal for ventilation, decoration, and sound insulation)

Square Holes, Rectangular Holes, and Triangular Holes (Commonly used for filtration, screening, and mechanical protection)

Pentagon Holes, Hexagonal Holes, and Figure-Eight Holes (Used for decorative applications, artistic designs, and building facades)

Cross Holes, Plum Blossom Holes, and Diamond Holes (Enhance aesthetic appeal, suitable for modern architectural designs)

Fish Scale Holes, Louvered Holes (Excellent for ventilation, heat dissipation, and noise reduction)

Embossed Round Holes, Crocodile Mouth Holes· (Anti-slip designs, commonly used in flooring and walkways)

Additionally, we offer fully customized perforations based on customer-supplied design drawings or specific requirements. Hole sizes, spacing, and arrangement patterns can be personalized to meet functional and aesthetic demands for particular projects.

Application Fields of Perforated Aluminum Sheets

With its outstanding performance, perforated aluminum sheets play a crucial role in numerous industries. Some specific applications include:

Architectural Decoration: Used in curtain walls, ceilings, railings, and stair handrails

Industrial Protection: Protective covers for machinery, factory ventilation panels, and screening nets

Environmental Soundproofing: Highway noise barriers, subway soundproof walls, and noise reduction equipment

Filtration and Screening: Filtration and screening meshes for food processing and the chemical industry

Transportation Infrastructure: Used in subway stations, airports, and highway guardrails

Why Choose Perforated Aluminum Sheets?

Excellent Corrosion Resistance: Aluminum naturally resists oxidation and has superior weather resistance, making it ideal for outdoor use.

Lightweight with High Strength: Compared to stainless steel and iron, aluminum sheets are lighter in weight, making transportation and installation more convenient.

Aesthetic and Breathable with Strong Design Flexibility: Available in various color coatings and electroplating treatments to enhance decorative effects.

Customizable Production: Meets personalized demands and adapts to diverse application scenarios.