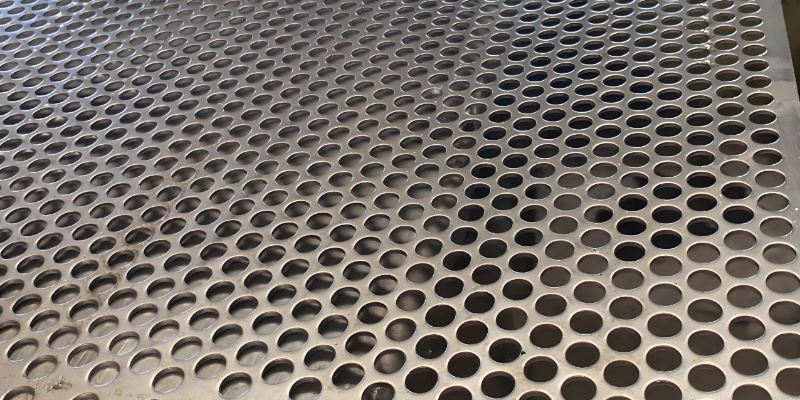

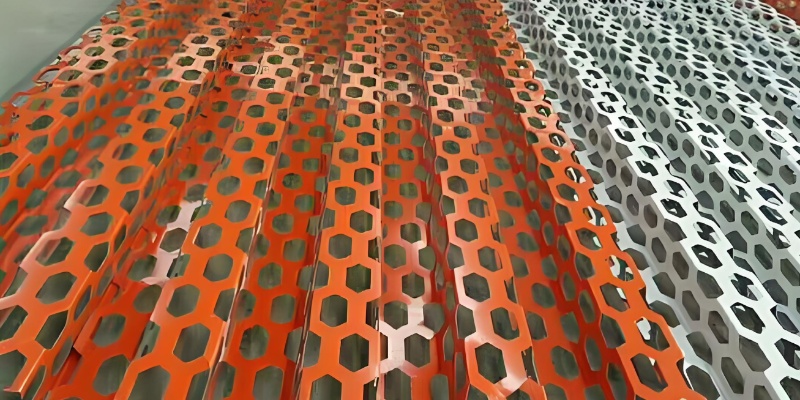

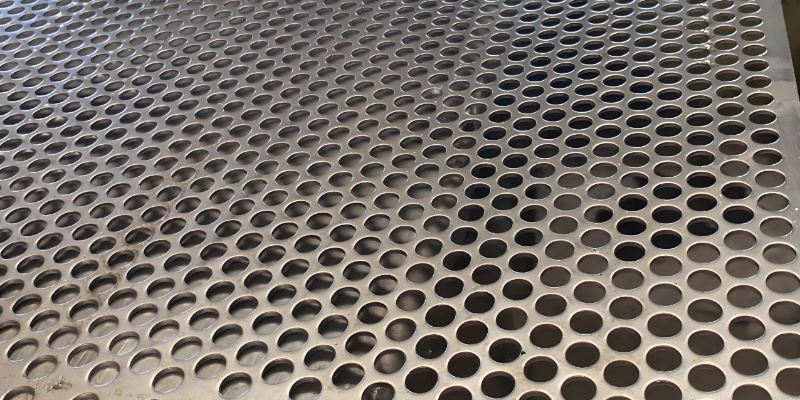

Analysis of Common Materials and Characteristics of Perforated Metal Sheets

Source:www.cn-psp.cnAuthor:河北森驰公司 Last updated:2025-03-08 16:07:36 Browse:

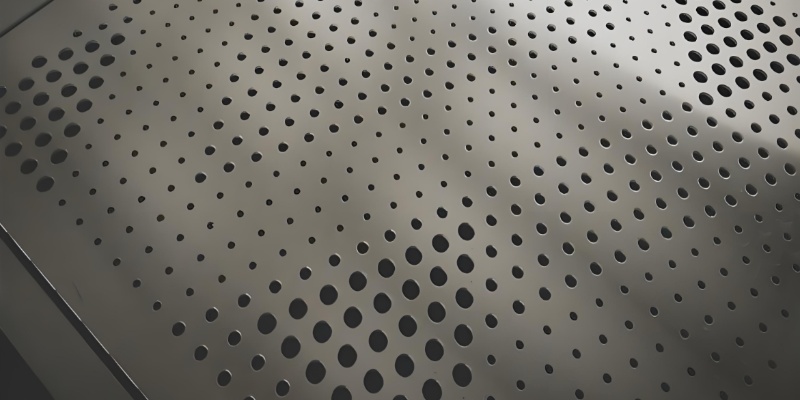

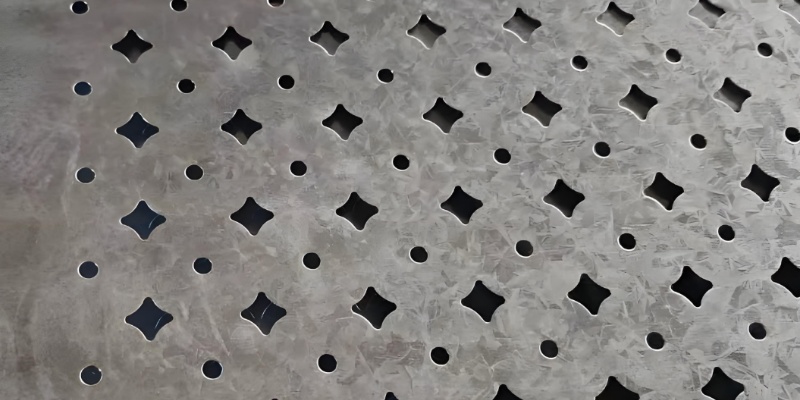

Perforated metal sheets are available in a variety of materials, with the most common ones including stainless steel, aluminum sheets, galvanized steel, hot-rolled steel, manganese steel, cold-rolled steel, and copper sheets. Depending on the material used, perforated metal sheets find widespread application in architectural decoration, industrial screening, mechanical protection, soundproof ceilings, ventilation noise reduction, and other fields. Below we provide an in-depth introduction to the characteristics of several commonly used materials, helping you select the most suitable product based on your needs.

Features: Excellent corrosion resistance, high strength, strong decorative appeal

Capable of withstanding dampness and acidity/alkalinity, making it particularly suitable for outdoor environments, high humidity areas, or chemical industries with strong corrosivity.

Supports surface treatments like electropolishing, brushing, and coating, widely used in decoration to enhance aesthetic appeal while offering high hardness and impact resistance.

Food-grade stainless steel sheets are also available for use in food processing environments.

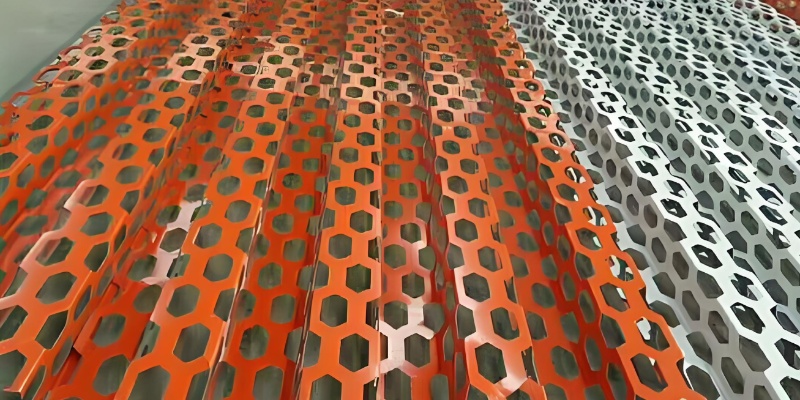

Features: Lightweight yet strong, corrosion resistant with good formability

Advantages:

Weight savings: Lower density than stainless steel and ordinary steel, facilitating handling and installation, ideal for high-rise buildings or ceilings.

Superior oxidation resistance: A natural oxide layer on the surface provides excellent corrosion protection; can undergo anodizing, painting, or electrophoresis for better aesthetics and durability.

Excellent processability: Good ductility allows easy stamping, bending, and welding; customizable into various shapes and patterns.

Applications: Curtain wall decoration, ceiling panels, ventilation systems, advertising signs, window decoration, etc.

Recommendation: Ideal choice when lightweight and high decorative value are needed for building facades, ceilings, or interior decoration.

Features: Economical yet durable with strong rust prevention

Advantages:

Cost-effective: More competitive pricing compared to stainless steel, suitable for large-scale industrial applications.

Strong rust resistance: Zinc coating effectively prevents rust formation, extending service life especially in moist conditions.

High tensile strength: Offers greater load-bearing capacity compared to aluminum alloys.

Applications: Industrial protection, machinery guards, sieving screens, fencing, ventilation equipment, etc.

Recommendation: Excellent option for economical and long-lasting solutions in industrial protection, fencing, and machinery applications.

Features: High strength, excellent impact resistance at low cost

Advantages:

Superior strength and toughness: Heat-treated structure provides outstanding impact absorption and deformation resistance.

Rough surface finish: Facilitates paint adhesion; requires anti-corrosion coating.

Good processability: Suitable for cutting, stamping, and bending operations.

Applications: Machinery manufacturing, bridge construction, building steel structures, industrial equipment, etc.

Recommendation: Best suited for heavy-duty industrial and construction applications requiring high load-bearing capacity but not demanding smooth surface finish, such as bridges and machinery production.

Features: Abrasion resistant, impact resistant, and pressure resistant

Advantages:

Extraordinary wear resistance: 11-14% manganese content causes "work hardening" under impact, enhancing surface hardness.

Strong impact resistance: Absorbs energy through deformation instead of breaking.

Moderate corrosion resistance: Requires additional paint or coating for enhanced protection.

Applications: Mining equipment, screening meshes, wear-resistant lining plates, construction machinery, etc.

Recommendation: Ideal for high-impact, high-friction, and heavy-load applications in mining, construction machinery, and heavy equipment.

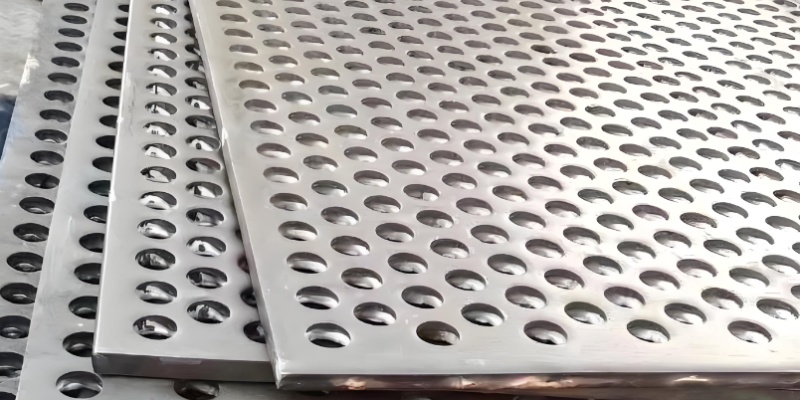

Features: Smooth surface, high precision, and good processability

Advantages:

High surface quality: Smooth finish from the cold rolling process with precise dimensions.

Good strength and ductility: Facilitates subsequent processes like stamping and welding.

Requires anti-corrosion treatment: Needs galvanizing or painting to prevent rusting.

Applications: Automobile manufacturing, appliance casings, industrial components, electronic equipment, etc.

Recommendation: Suitable for applications requiring high surface quality and ease of processing, such as home appliances, automotive parts, and electronics.

7.Copper Perforated Sheets

Features: Excellent electrical conductivity, strong antimicrobial properties, and superior decorative appeal

Advantages:

Outstanding conductivity: Second only to silver, widely used in electronics and electrical industries.

Antimicrobial effect: Copper ions kill bacteria, suitable for medical and food processing environments.

High-end decorative effect: Unique metallic luster makes it popular in luxurious architecture and classical decoration.

Applications: Electromagnetic shielding devices, high-end architectural decoration, medical equipment, food processing, etc.

Recommendation: Perfect choice when electrical conductivity, antimicrobial properties, or premium decoration are required.

Summary: How to Choose the Right Perforated Metal Sheet?

Each material has its unique advantages. Selection should consider factors like corrosion resistance, strength, weight, decorative requirements, and cost. For example:

Stainless steel sheets are suitable for high corrosion resistance and upscale decoration.

Aluminum sheets are ideal for lightweight and highly decorative applications.

Manganese steel sheets are best for abrasive and impact-intensive industrial uses.

Copper sheets are recommended for electrical/electronic applications and premium decoration.

If you need customized perforated sheets of different materials and specifications, please feel free to contact us for professional tailor-made services!