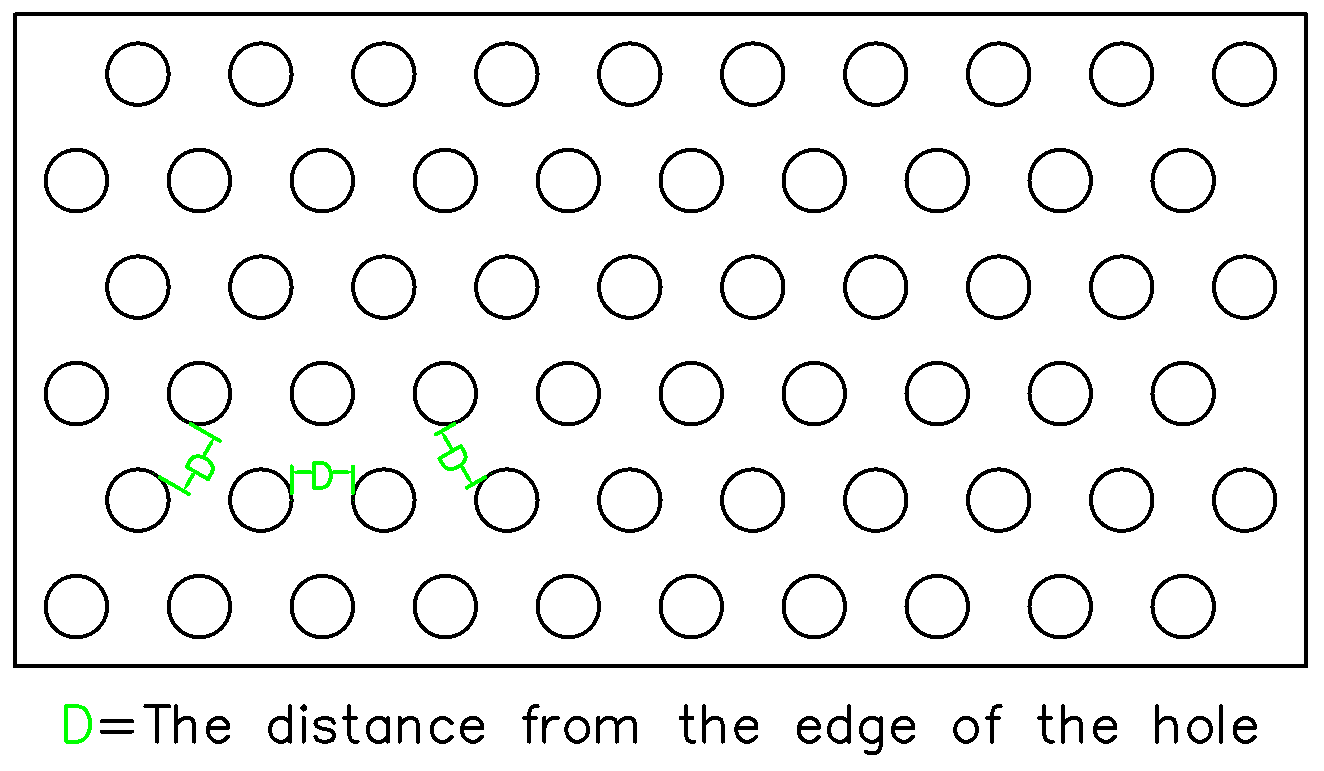

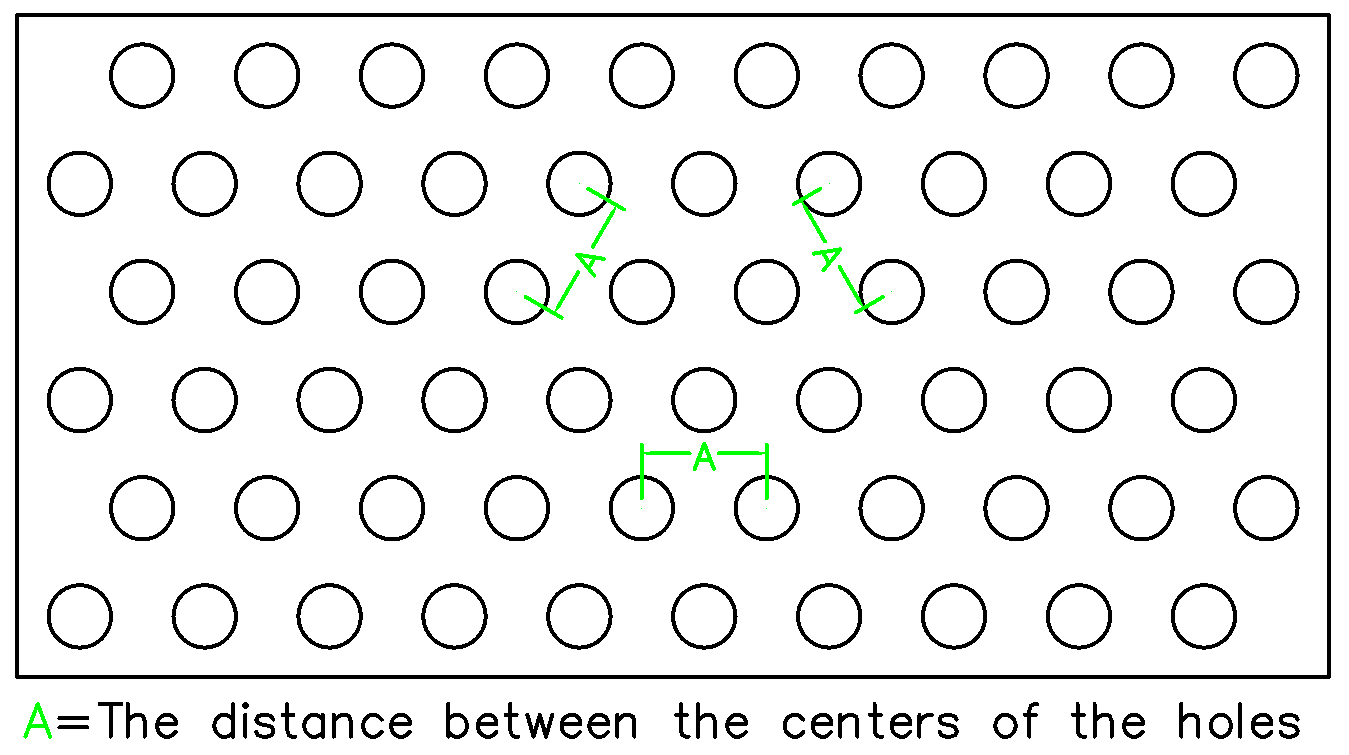

Importance of Pitch Design

1. Structural Strength

Proper pitch design ensures that the perforated sheet resists deformation or cracking under external forces, which is crucial for load-bearing structures.

2. Functionality

Pitch affects airflow, light transmission, and sound propagation. Smaller pitches are suited for high-efficiency filtration, while larger pitches facilitate better ventilation.

3. Aesthetics

In architectural decoration, the uniformity and pattern of pitch directly influence the visual appeal, enhancing overall design aesthetics.

Practical Applications

Architectural Facades

Accurately designed pitch allows perforated sheets to be used as building facades, providing shading, ventilation, and unique visual effects.

Industrial Filtration

In industries such as chemical processing and food production, perforated sheets serve as filtration media, where pitch selection directly impacts filtering precision and efficiency.

Acoustic Control

Perforated sheets with appropriate pitch are used in auditoriums and conference rooms for sound absorption, improving acoustic performance.

Design Recommendations

Define Requirements: Determine hole size, pitch, and pattern based on specific application needs.

Consider Material Properties: Different materials affect processing and performance, which should be factored into design.

Communicate with Manufacturers: Collaborate closely with manufacturers during design to ensure feasibility and cost-effectiveness.

Conclusion

Pitch is a key parameter in perforated metal sheet design, influencing functionality, structural integrity, and aesthetics. Understanding its definition, measurement, and design considerations helps achieve more efficient, economical, and visually appealing solutions.

For more information about perforated metal sheets, please visit our official website or contact our professional team.