What are the smooth and rough sides of perforated sheets?

Source:www.cn-psp.cnAuthor:河北森驰公司 Last updated:2025-04-06 10:12:20 Browse:

The smooth and rough sides of perforated metal sheets refer to the surface characteristics produced by the punching process during production. Below is a detailed explanation:

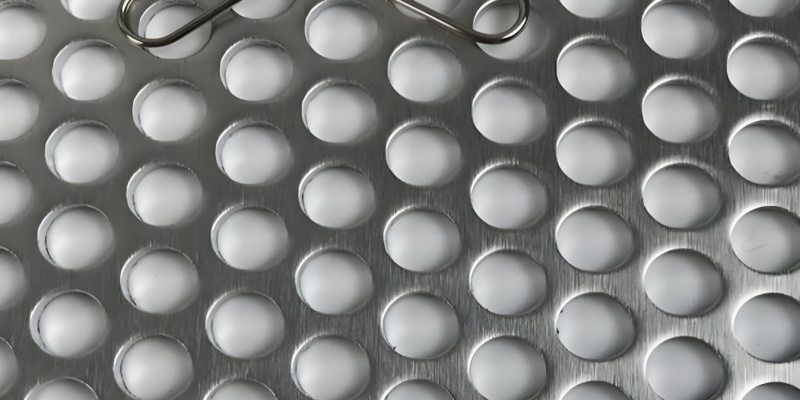

Smooth Side

During the perforation process, the top side of the metal sheet, which comes into direct contact with the surface of the punch press, remains relatively flat and smooth. This side is called the smooth side and is usually preferred in situations where aesthetics are more important.

Perforated sheets with a smooth side

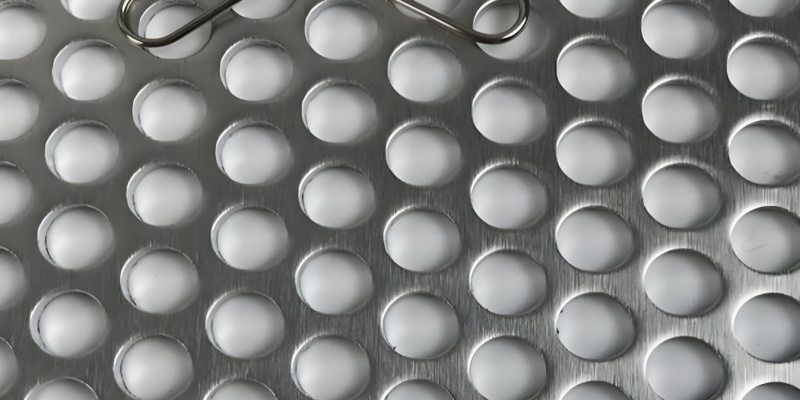

Rough Side

As the punch press applies pressure downward, slight burrs or marks may form around the perforations on the bottom side of the metal sheet. This surface is called the rough side.

Perforated sheets with a rough side

Selection of smooth and rough sides in subsequent processing

It is crucial to identify the smooth and rough sides when performing subsequent processing (such as bending or rolling). Typically, the smooth side faces outward while the rough side faces inward, ensuring that the final product meets higher quality standards, especially in applications where appearance is critical.

Application examples

Facade decoration and ceilings: In decorative applications, the smooth side is displayed outward while the rough side is hidden.

Industrial applications: In situations where functionality is prioritized, the choice between the smooth side or the rough side varies according to specific needs; however, the smooth side is generally used where less friction or a smoother appearance is required.

Key considerations in production

Die installation: Ensure proper alignment of the punch press die to minimize burr formation on the rough side.

Wear of punching tools: Regularly check the wear condition of the punching tools to maintain the quality of the perforated sheets.

Proper differentiation and reasonable utilization of the smooth and rough sides of perforated sheets not only enhance the appearance of the final product but also ensure a simpler processing procedure, further improving overall quality.

Perforated Sheet