High Flow Rate per Unit Area:

With a design that promotes efficient fluid or air passage, these sheets achieve a high flow rate, which is crucial in filtration and ventilation systems.

Adaptability to Temperature Extremes:

Whether used in low or high temperature conditions, stainless steel perforated sheets maintain their structural integrity and performance.

Ease of Maintenance and Reusability:

One of the major advantages is that they can be easily cleaned and reused. This not only extends their lifespan but also reduces the overall cost by eliminating frequent replacements.

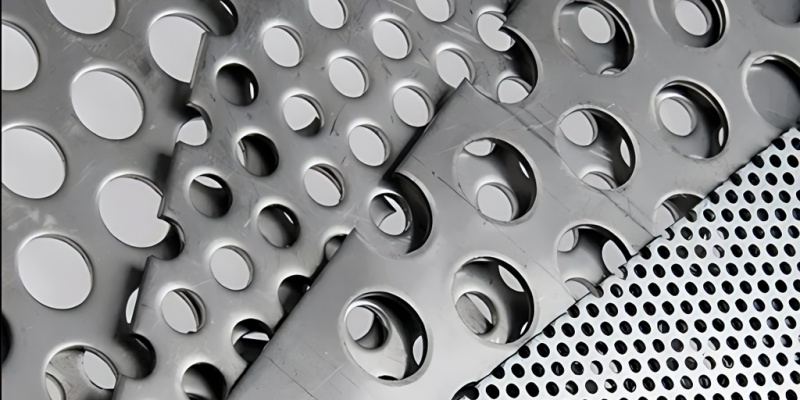

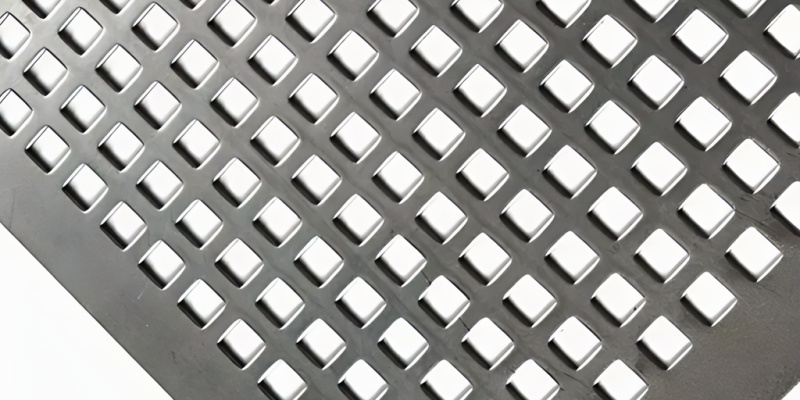

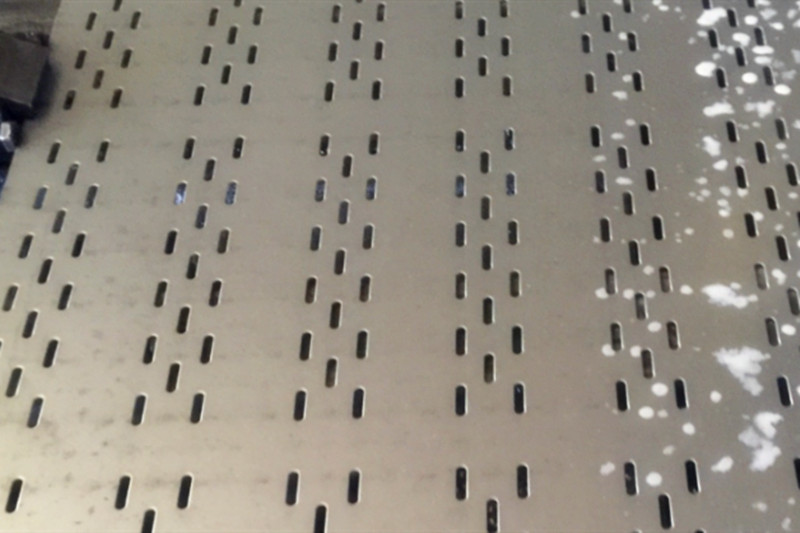

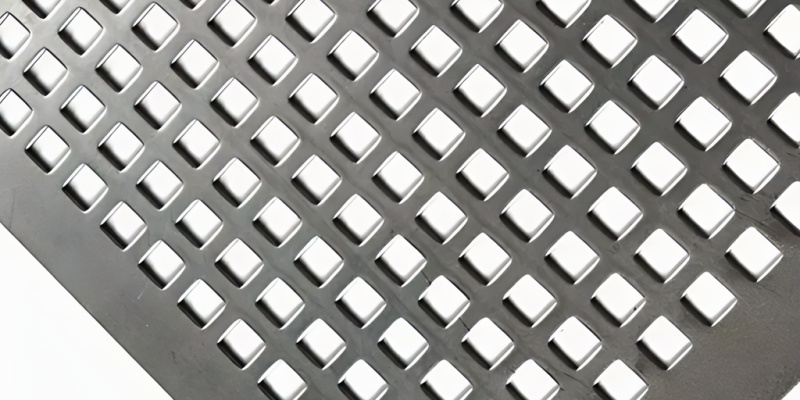

Customization and Precision:

Available in various patterns and hole configurations, these sheets can be customized to meet specific requirements, ensuring uniform precision in manufacturing and design processes.

Diverse Applications of Stainless Steel Perforated Sheets

The unique properties of stainless steel perforated sheets have led to their adoption in a variety of fields. Here are some of the most common applications:

Architectural Decorative Panels:

They are widely used in building facades and interior design due to their modern look and ability to allow light and ventilation.

Mechanical Equipment Protection:

Their robust nature makes them ideal for protective screens in machinery and industrial equipment, ensuring safety and longevity.

Craft and Industrial Manufacturing:

Perforated sheets serve as a key material in various craft and manufacturing processes, where precision and durability are paramount.

Speaker Grilles:

The aesthetic and functional design of these sheets makes them popular for speaker covers, ensuring both sound quality and durability.

Grain Ventilation and Cooling:

In agricultural and storage applications, perforated sheets facilitate proper air circulation to keep grains cool and dry.

Screening in Mining, Chemical, and Food Industries:

They are essential for screening and separation processes, from mining operations to chemical processing and food grading.

Water and Oil Filtration:

Thanks to their excellent filtration properties, these sheets are used in systems that require effective separation of contaminants from fluids.

Kitchen Utensils and Equipment:

Their corrosion resistance and ease of cleaning make them suitable for everyday kitchen applications and professional food processing equipment.

Mechanical Equipment Screen Mesh Panels:

Used as protective mesh panels, these sheets enhance safety and functionality in industrial settings.

Road and Factory Protection Barriers:

Their strength and durability also lend themselves to use in protective barriers, providing both security and a modern aesthetic in infrastructure projects.

Additional Benefits and Considerations

Beyond their primary characteristics and uses, stainless steel perforated sheets offer several additional benefits:

Environmental Sustainability:

Their reusability and long service life contribute to reduced waste, making them a more sustainable option compared to disposable materials.