What is a Metal Perforated Sheet? What Are the Common Types?

Source:www.cn-psp.cnAuthor:河北森驰公司 Last updated:2025-03-04 13:16:18 Browse:

What is a Metal Perforated Sheet?

A metal perforated sheet is a type of metal sheet processed using CNC punching or laser cutting technology, featuring regularly or irregularly arranged small holes on its surface. The hole size, spacing, shape, sheet thickness, dimensions, and shape can all be customized according to specific requirements. Due to its unique physical properties and aesthetic appeal, metal perforated sheets are widely used in architecture, decoration, industrial equipment, mechanical manufacturing, and environmental protection.

Main Functions and Advantages of Metal Perforated Sheets

Sound Absorption and Noise Reduction: The porous structure effectively absorbs sound, making it ideal for sound systems, conference rooms, theaters, and more.

Ventilation and Light Transmission: It helps regulate airflow and lighting, commonly used in ventilation systems and building facades.

Filtration and Protection: Widely applied in industrial filtration, food processing equipment, and safety protection nets.

Aesthetic Appeal: Various materials and hole patterns cater to personalized design needs for indoor and outdoor decoration.

Based on the material used, metal perforated sheets can be classified into aluminum perforated sheets, stainless steel perforated sheets, galvanized steel perforated sheets, carbon steel perforated sheets, and copper perforated sheets. Each type has its specific properties and applications. For example, aluminum perforated sheets are lightweight and corrosion-resistant, making them popular for architectural decoration, while stainless steel perforated sheets offer high strength and heat resistance, suitable for industrial equipment.

Common Types of Metal Perforated Sheets

Classification by Material

Aluminum Perforated Sheet: Lightweight, corrosion-resistant, and easy to process, widely used in building facades, ceilings, and interior decoration.

Common materials: 1060, 3003, 3004, 5052, 5083, 6061.

Stainless Steel Perforated Sheet: High strength, heat-resistant, and oxidation-resistant, suitable for industrial filtration, kitchen equipment, and outdoor facilities.

Common materials: 201, 304, 310S, 316, 316L, 430, 2205.

Common materials: Q195, Q235, Q355.

Copper Perforated Sheet: Beautiful appearance and excellent conductivity, often used in high-end decoration and electronic devices.

Common types: Brass sheets, red copper sheets.

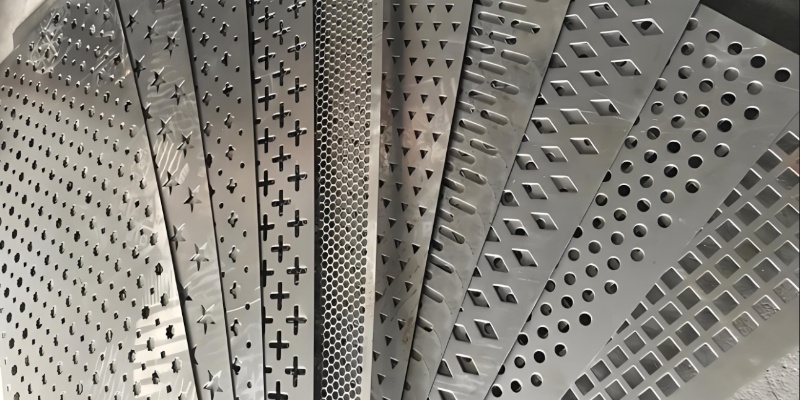

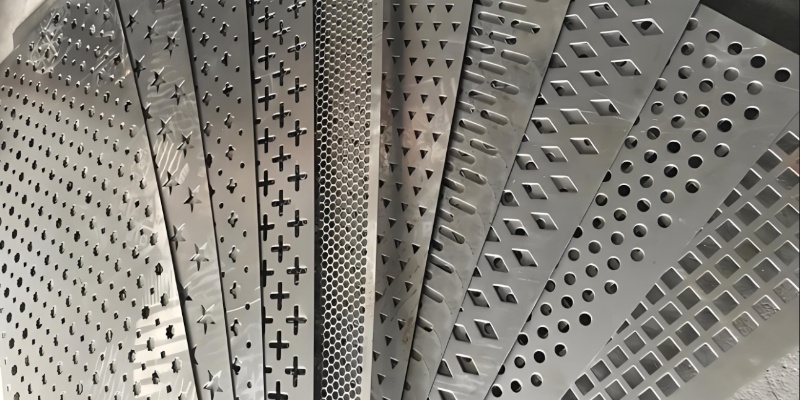

Classification by Hole Type

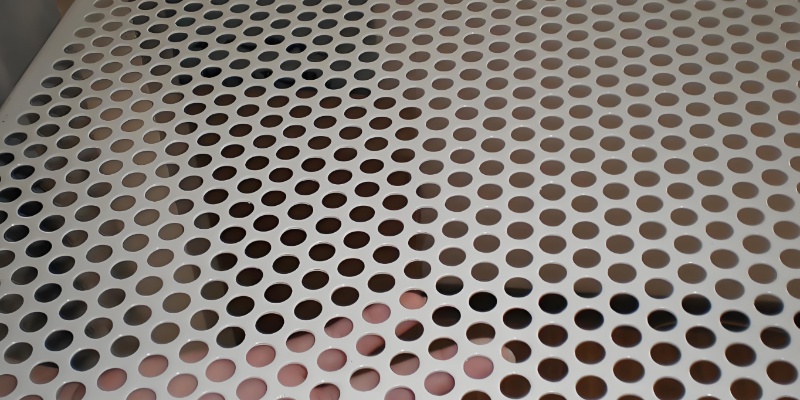

Round Hole Perforated Sheet: The most common type, offering excellent ventilation and acoustic performance, widely used in soundproof walls and speaker covers.

Diamond Hole Perforated Sheet: Aesthetically pleasing and practical, often used in architectural decoration.

Custom-Shaped Perforated Sheet: Tailored to specific designs and applications.

Classification by Application

Decorative Perforated Sheets: Used for facades, partitions, screens, ceilings, and other design projects.

Functional Perforated Sheets: Includes acoustic panels, filter screens, protective covers, emphasizing practical functionality.

Industrial Perforated Sheets: Designed for food processing, pharmaceuticals, and mechanical equipment filtration components.

Environmental Perforated Sheets: Used in air purification and water treatment filtration systems.

How to Choose the Right Metal Perforated Sheet?

When selecting a metal perforated sheet, consider the following factors:

Usage Environment: For outdoor applications, choose corrosion-resistant materials such as aluminum or stainless steel.

Functional Requirements: For sound absorption, opt for perforated sheets with a higher open area.

Strength Requirements: Industrial applications require high-strength materials like stainless steel or carbon steel.

Aesthetic Considerations: Decorative perforated sheets can be customized in color, patterns, and surface treatments.

Conclusion

Metal perforated sheets, with their diverse hole designs, excellent physical properties, and wide range of applications, have become essential materials in modern architecture, industrial manufacturing, and environmental engineering. Whether for aesthetic decorative purposes or functional industrial applications, metal perforated sheets provide ideal solutions. If you need high-quality customized metal perforated sheets, we offer professional manufacturing services to meet your specific requirements.