Production Process and Features of Stainless Steel Perforated Sheets

Source:www.cn-psp.cnAuthor:河北森驰公司 Last updated:2025-03-04 10:25:54 Browse:

Stainless steel perforated sheets are materials produced through high-precision CNC punching machines and specific molds for continuous punching. They are widely used in various industries. The raw materials used in the production process are various grades of stainless steel, including common materials such as 201 stainless steel, 304 stainless steel, and 316 stainless steel. Other grades of stainless steel can also be used according to customer requirements. This diverse material selection meets the needs of different environments for stainless steel, making it suitable for various special application scenarios.

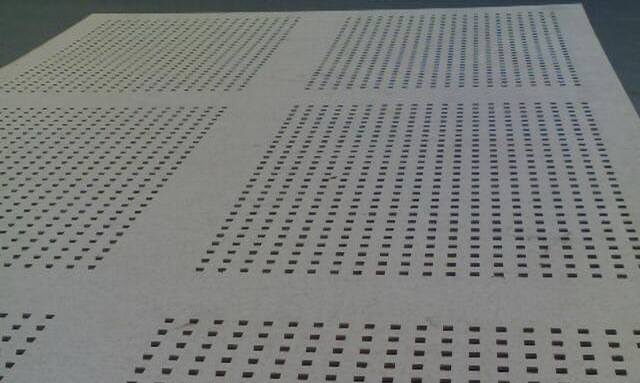

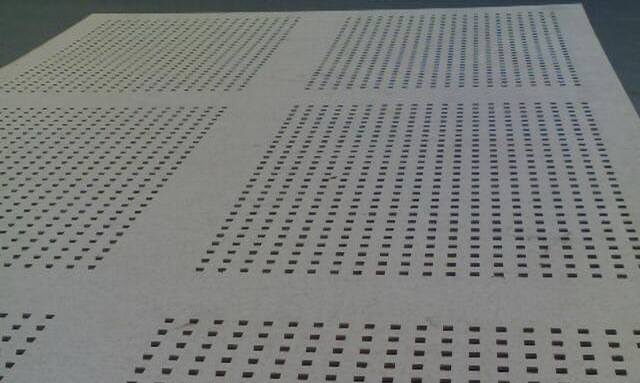

Stainless Steel Perforated Sheets

Material Selection:The material options for stainless steel perforated sheets are extensive. Not only can common grades such as 304 and 316 stainless steel be used, but customers can also choose different grades of stainless steel according to their specific requirements. This ensures that the perforated sheets perform excellently in various working environments, especially in conditions requiring corrosion resistance or high-temperature durability.

Hole Patterns:Stainless steel perforated sheets come in a wide variety of hole patterns, satisfying the demands of different industries. Common hole patterns include round holes, oval holes, elongated round holes, square holes, rectangular holes, triangular holes, star-shaped holes, hexagonal holes, diamond holes, cross-shaped holes, plum blossom holes, rhombic holes, fish-scale holes, louver holes, raised round holes, crocodile-mouth holes, and more. These hole patterns can be customized according to needs, and the hole size and spacing can also be tailored to specific requirements.

Sheet Thickness:Stainless steel perforated sheets come in a wide range of thicknesses, from 0.1mm to 20mm. This variety allows the perforated sheets to be used in different applications, accommodating scenarios that require anything from thin to thick sheets.

Production Process and Advantages:The production process uses precision CNC punching machines for continuous punching, eliminating the need for traditional semi-automatic punching methods. This modern production technique significantly improves production efficiency, shortens lead times, and reduces labor and production costs. As a result, stainless steel perforated sheets are more cost-effective, providing excellent value for money.