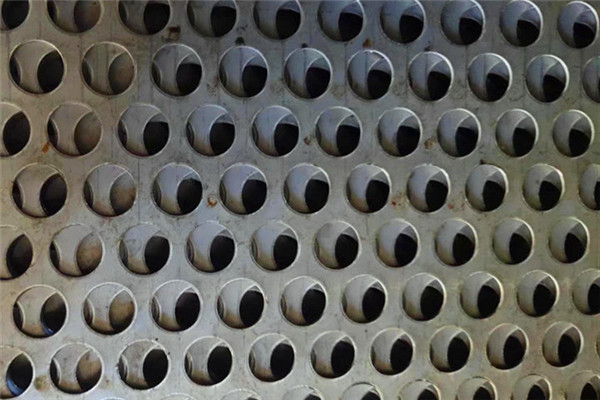

The raw material of Stainless steel perforated sheet is made of stainless steel plate, the material selection is rich, the conventional Stainless steel perforated sheet material has 201 material, 304 material, 316 material, 430 material and so on, then what is the difference between different materials Stainless steel perforated sheet?

201Stainless steel perforated sheet : 201Stainless steel perforated sheet is composed of (C) carbon :≤ 0.15, (Si) Silicon :≤ 1.00, (Mn) manganese :5.5 ~ 7.50, (Cr) Chromium :16.0 ~ 18.0, (N) nitrogen :≤ 0.25, (P) phosphorus :≤ 0.060, (S) sulfur :≤ 0.030, (Ni) nickel: 3.5-5.5, is a Ni steel, 301 steel replacement steel. High manganese content, the surface is very bright with dark bright, high manganese content is easy to rust, and it is magnetic after cold processing.

304Stainless steel perforated sheet : 304Stainless steel perforated sheet is composed of carbon ≤ 0.08, silicon ≤ 1.00, manganese ≤ 2.00, phosphorus ≤ 0.045, sulfur ≤ 0.03, nickel 8.0-10.5, chromium 18-20, high temperature resistance is better, the use of temperature limit is less than 650℃, with good rust corrosion resistance and good resistance to intergranular corrosion performance.

316Stainless steel perforated sheet : 316Stainless steel perforated sheet is composed of carbon C: ≤ 0.08, silicon Si: ≤ 1.00, manganese Mn: ≤ 2.00, sulfur S: ≤ 0.030, phosphorus P: ≤ 0.035, chromium Cr: 16.00 ~ 18.50, nickel Ni: 10.00 ~ 14.00, Mo: 2.00 ~ 3.00. Due to the addition of Mo, its corrosion resistance, atmospheric corrosion resistance and high temperature strength are particularly good, and can be used under harsh conditions; Excellent work hardening (non-magnetic).

430Stainless steel perforated sheet : 430Stainless steel perforated sheet is composed of carbon (C) :≤ 0.12%, Silicon (Si) :≤ 0.75%, Manganese (Mn) :&le 1.00%, Phosphorus (P) :≤ 0.040%, sulfur (S) :≤ 0.030%, nickel (Ni) :≤ 0.60% (can include), chromium (Cr) :16.00~18.00%, general steel with good corrosion resistance, better thermal conductivity than austenite, smaller thermal expansion coefficient than austenite, heat resistance fatigue, adding stabilizing element titanium, good mechanical properties of weld parts.

2025-03-06

2025-03-04

2024-05-26

2025-03-03

2024-06-26

2025-03-03

2025-03-04

2025-03-04

2024-05-26

2024-09-29