Safety Guidelines for Perforated Metal Sheet Production: Protecting Workers and Enhancing Efficiency

Source:www.cn-psp.cnAuthor:河北森驰公司 Last updated:2025-06-07 18:18:35 Browse:

Safety is a critical factor in the production of perforated metal sheets. It not only safeguards workers' health but also ensures smooth production and high product quality. By establishing a comprehensive safety management system and implementing effective protective measures, manufacturers can prevent accidents and create a secure, efficient working environment.

1. Safety Management of Punching Equipment

Punching machines are the core of perforated sheet manufacturing. Their safe operation directly affects both employee safety and production stability.

Adoption of Automated Equipment:

Traditional manual punching presses pose high operational risks, especially hand injuries. Implementing CNC (Computer Numerical Control) automated punching systems significantly reduces human error, improving safety and boosting productivity.

Regular Maintenance and Inspections:

Scheduled maintenance is essential for preventing mechanical failure and operational hazards. A detailed maintenance plan should be in place, with timely replacement of worn components to keep machinery in optimal working condition.

2. Operator Guidelines and Safety Training

The competence and safety awareness of machine operators are key to maintaining a secure production environment.

Training for New Employees:

All new hires must undergo structured safety training to fully understand machine operations, safety procedures, and emergency response actions before beginning independent work.

Continuous Education for Experienced Staff:

Veteran employees can become complacent due to familiarity with equipment. Regular safety refreshers help maintain alertness and adherence to safety protocols.

3. Preventing Accidents from Fatigue

Extended high-intensity work can cause worker fatigue, leading to a decline in attention and higher accident risk.

Balanced Work Schedules:

Establishing scientific shift rotations and adequate break times ensures employees stay alert and focused during work.

Monitoring Physical and Mental Health:

Supervisors should pay attention to workers’ well-being and adjust tasks as needed to avoid stress- or fatigue-induced incidents.

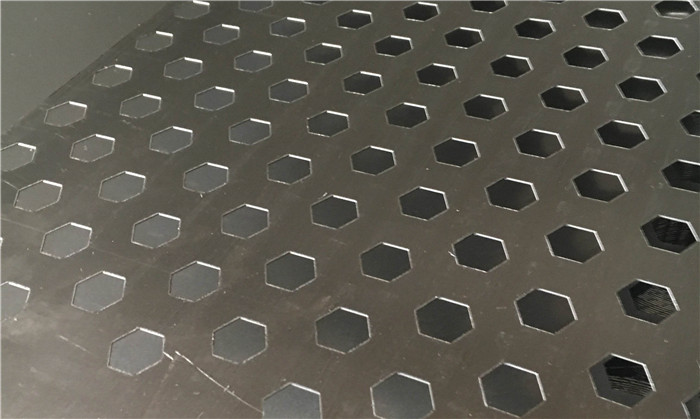

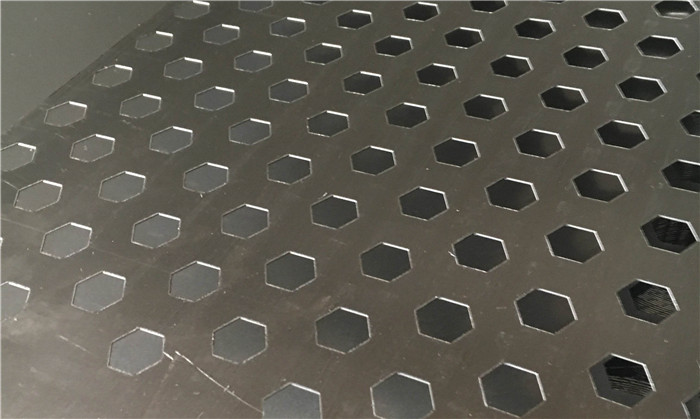

Perforated Sheets

4. Strengthening Safety Awareness and Culture

A strong safety culture encourages employees to proactively follow regulations and creates a workplace where everyone prioritizes safety.

Ongoing Safety Training:

Organizing regular safety sessions, including emergency drills and knowledge workshops, enhances safety awareness and response skills.

Incentive Programs:

Recognizing and rewarding employees for outstanding safety performance motivates others to actively participate in safety practices.

5. Proper Use of Personal Protective Equipment (PPE)

Using appropriate PPE is essential in minimizing risks during punching operations.

Provide Suitable Protective Gear:

Equip workers with job-specific PPE, such as gloves, safety glasses, and noise-reducing earmuffs.

Ensure Correct Usage:

Train workers on how to properly wear and use PPE, inspect gear regularly, and replace damaged items promptly to maintain protection levels.

By applying these measures, companies can significantly enhance the safety of perforated metal sheet manufacturing, reduce incident rates, protect employee well-being, and boost productivity and competitiveness.

If you are looking for professional safety consultation or tailored safety training services for your perforated metal sheet production line, feel free to contact us. We are committed to supporting your business with practical, results-oriented safety solutions.