How to Ensure the Quality of Perforated Sheets

Source:www.cn-psp.cnAuthor:河北森驰公司 Last updated:2025-03-04 10:33:21 Browse:

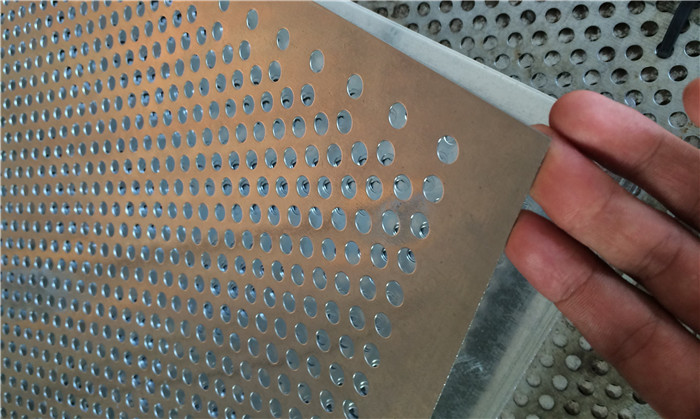

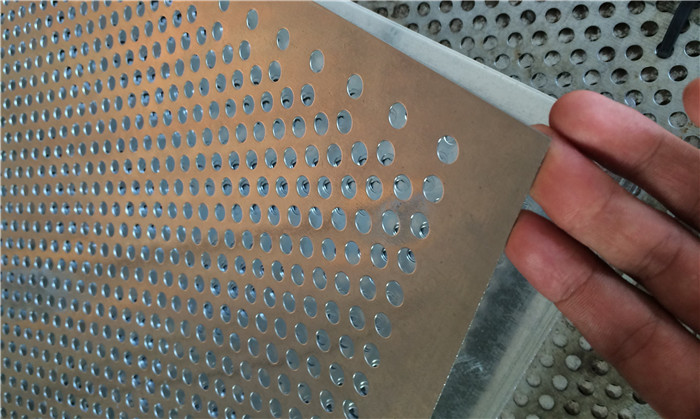

Perforated sheets are widely used in various fields due to their excellent characteristics, such as sound absorption, noise reduction, and aesthetic appeal. They can be used as protective barriers in transportation sectors like highways, railways, and subways. They are also used as protective screens for machinery, offering durability and long service life. In water treatment plants, sewage treatment plants, and aquaculture, they serve as anti-slip grating with excellent slip resistance. Additionally, perforated sheets are used in screening applications due to their high screening accuracy and long lifespan, as well as in drying equipment for their good ventilation and heat dissipation. So, how can we ensure the quality of perforated sheet products? The following key points are essential:

Perforated Sheets

Select Qualified Raw Materials:The first step in ensuring the quality of perforated sheets is to choose high-quality raw materials. The material of the base sheet directly affects the performance and service life of the perforated sheet, so it is crucial to carefully select raw materials that meet the required standards.

Equipment Maintenance and Precision Testing:The equipment used to produce perforated sheets plays a key role in ensuring product quality. Regular maintenance and checks are necessary to ensure that mechanical gaps are correct and that the equipment can achieve the required precision. Only when the equipment is in optimal condition can perforated sheets of high accuracy be produced.

Control Cutting Precision:After the perforated sheet is produced, it needs to be cut to size. During the cutting process, the error should be minimized to ensure that the finished product’s dimensions meet the design specifications. Accurate cutting affects not only the product’s appearance but also its functionality.

Importance of Flattening:After production, perforated sheets should undergo a flattening process, especially if there is significant deformation. During the flattening process, multiple passes may be needed to ensure the sheet reaches the best possible flatness, enhancing the overall quality and performance of the product.