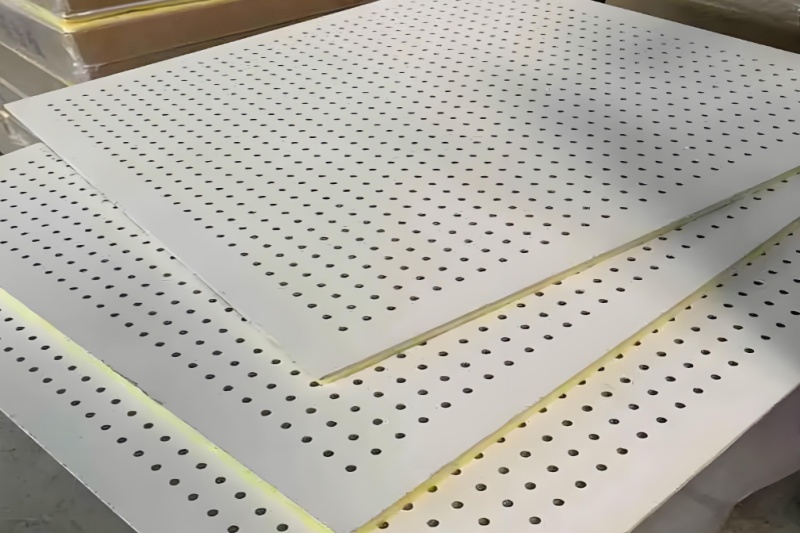

Perforated silencer boards are widely used in various noise reduction applications, including automotive exhaust systems, building ceilings, curtain wall decorations, sound insulation barriers, and other fields that require sound absorption and noise reduction. We offer customized solutions based on customer requirements, providing different specifications, materials, and designs to meet diverse needs.

Perforated Silencer Board Specifications

Perforated silencer boards come in various specifications, and users can customize the size, thickness, material, hole shape, and hole diameter based on specific requirements. Common specifications include:

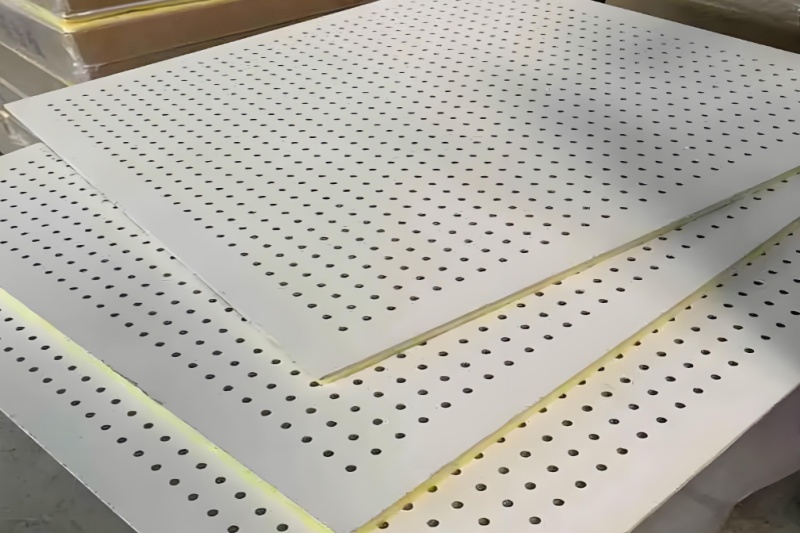

Sheet Size: Common sizes include 1m×2m, 1.25m×2.5m, 1m×20m, 1.2m×20m, etc., with a width generally less than 1.5 meters and length less than 4 meters. Custom sizes are available for special requirements.

Sheet Thickness: Custom thicknesses can be processed, ranging from 0.1mm to 20mm.

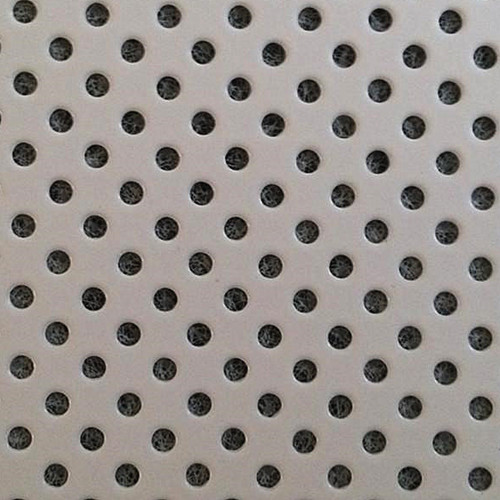

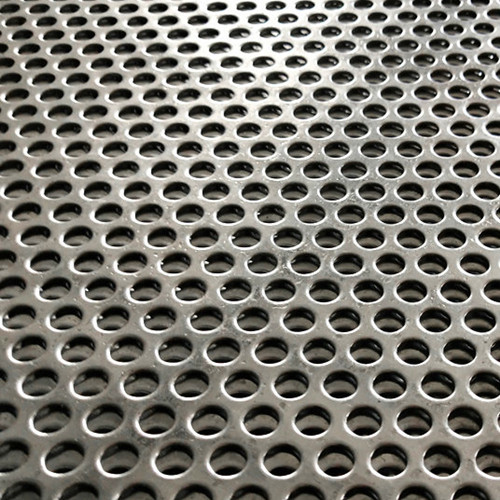

Sheet Material: Available in materials such as cold-rolled steel, hot-rolled steel, galvanized steel, manganese steel, aluminum, stainless steel, etc., to suit various environmental and functional needs.

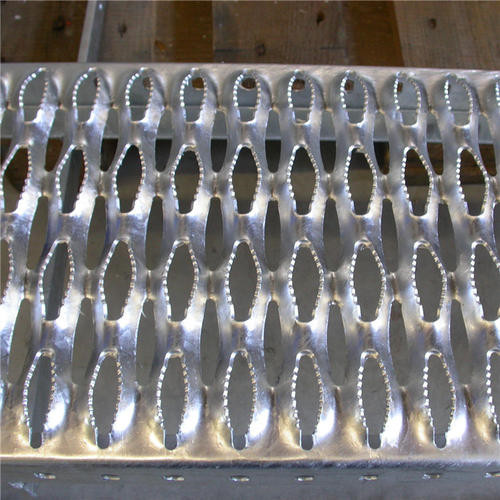

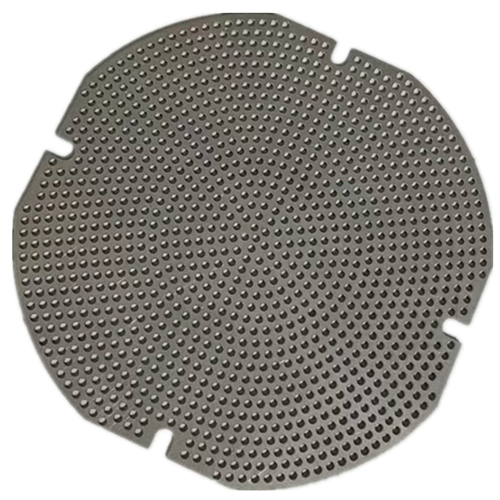

Hole Size and Shape: Hole diameters can be customized from 1mm to 300mm. Common hole shapes include round, oval, square, triangular, five-pointed star, hexagonal, eight-shaped, cross-shaped, zigzag, diamond, fish-scale, nail, bridge, louver, round drum, crocodile mouth, and more, offering diverse design options.

Surface Treatment: Different surface treatments are available based on the material, such as spray painting, fluorocarbon spraying, electrostatic powder coating, anodizing, electrolytic polishing, etc., to ensure durability and corrosion resistance.

Applications of Perforated Silencer Boards

Perforated silencer boards are widely used in the following areas due to their excellent acoustic performance and versatile designs:

Automotive and Motorcycle Mufflers: Effectively reduce engine noise, enhancing driving comfort.

Building Ceilings and Curtain Walls: In modern architecture, perforated silencer boards serve both decorative and acoustic functions, improving comfort and reducing noise in interior spaces.

Sound Insulation Barriers: Used in highways, airports, and industrial zones, perforated silencer boards can effectively absorb noise and reduce environmental noise pollution.

Public Spaces: In large public areas such as airports, train stations, and sports arenas, perforated silencer boards help optimize acoustics, improving sound quality and reducing noise interference.

Advantages of Perforated Silencer Boards

1.Efficient Noise Control: The unique hole design of perforated silencer boards effectively absorbs and reduces noise, optimizing the acoustic environment.

2.Customization: We offer tailored solutions in size, thickness, material, and hole design to perfectly match project needs.

3.High-Quality Materials and Craftsmanship: Using premium raw materials and advanced production techniques, we ensure high performance and durability for each silencer board.

4.Aesthetic and Functional: In addition to excellent sound absorption, perforated silencer boards' unique designs enhance the visual appeal of the space, combining functionality with aesthetics.

5.Durability: Whether for outdoor or indoor use, perforated silencer boards are durable and maintain their performance over time.

Perforated Silencer Board Pricing

The price of perforated silencer boards varies depending on specifications and models. Users can contact us for a specific quotation by providing the required specifications, materials, hole shapes, and other relevant details. We will offer an accurate quote based on your needs to ensure you get the best value for your investment.