What is the Difference Between Galvanized Steel Perforated Plate and Carbon Steel Perforated Plate?

Source:www.cn-psp.cnAuthor:河北森驰公司 Last updated:2025-03-09 15:21:34 Browse:

In the field of metal perforated plate applications, galvanized steel perforated plate and carbon steel perforated plate are two common material choices. Although they share similarities in certain aspects, there are significant differences in terms of manufacturing processes, performance, and application areas. This article will delve into the characteristics, advantages, disadvantages, and how to choose the right perforated plate for these two materials.

1. Material Differences

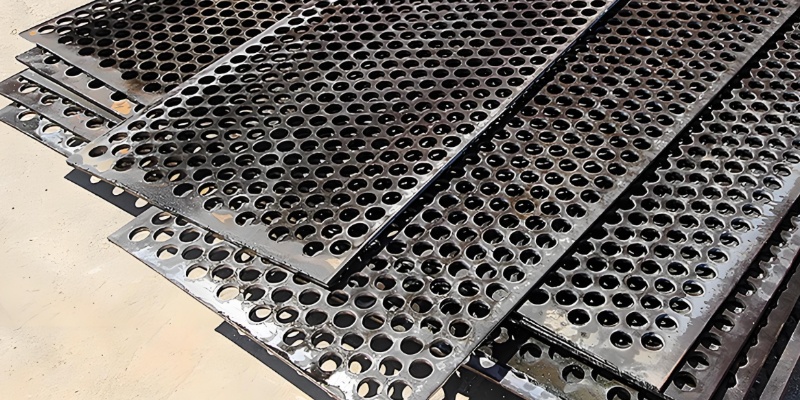

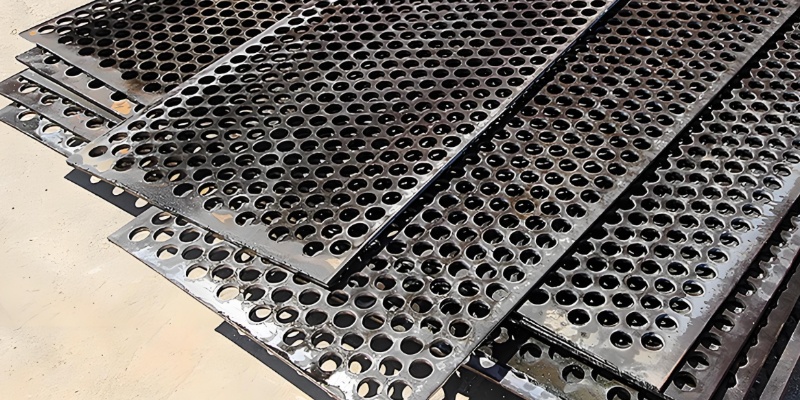

Carbon Steel Perforated Plate: Made from ordinary carbon steel, primarily composed of iron with a small amount of carbon, and may contain trace elements like manganese and silicon. Carbon steel lacks additional anti-corrosion layers, making it prone to rust when exposed to air and moisture.

Galvanized Steel Perforated Plate: Based on carbon steel, it undergoes a galvanizing process where a layer of zinc is applied to the surface, enhancing its anti-oxidation and anti-corrosion properties. Common galvanizing methods include hot-dip galvanizing and electro-galvanizing.

2. Corrosion Resistance

Carbon Steel Perforated Plate: Susceptible to rust, especially in humid or highly corrosive environments (e.g., coastal areas, chemical plants). Surface oxidation can quickly form rust, reducing its lifespan. Additional treatments like painting or powder coating are often required to improve corrosion resistance.

Galvanized Steel Perforated Plate: The zinc layer effectively isolates the steel from air and moisture, preventing rust and significantly enhancing corrosion resistance. Hot-dip galvanizing is more durable than electro-galvanizing, making it suitable for long-term outdoor or high-humidity environments.

3. Mechanical Properties

The mechanical properties of both materials depend on the quality and thickness of the carbon steel:

Carbon Steel Perforated Plate: Offers good strength and toughness but is prone to environmental degradation, leading to rust and reduced strength over time.

Galvanized Steel Perforated Plate: Maintains the original strength of carbon steel while improving wear resistance and impact resistance due to the zinc layer. However, excessive zinc thickness may affect machinability.

4. Appearance and Aesthetics

Carbon Steel Perforated Plate: Typically has a black or gray surface and is prone to oxidation, which can affect its appearance. Painting or powder coating can enhance its visual appeal.

Galvanized Steel Perforated Plate: The zinc layer gives it a silver-white or light-gray appearance with a glossy finish, making it suitable for applications where aesthetics are important.

5. Price and Cost

Carbon Steel Perforated Plate: Lower raw material cost, but additional anti-corrosion treatments (e.g., painting, powder coating) may increase overall expenses.

Galvanized Steel Perforated Plate: Generally more expensive due to the galvanizing process, but its longer lifespan and lower maintenance costs make it more cost-effective in the long run.

6. Main Application Areas

Carbon Steel Perforated Plate is Suitable for:

Machinery manufacturing, equipment guards

Architectural decoration, ceilings, and curtain walls

Industrial filtration and ventilation equipment

Applications requiring high mechanical pressure but low anti-corrosion demands

Galvanized Steel Perforated Plate is Suitable for:

Outdoor guardrails and fences

Marine environments and high-humidity factories

Ventilation and soundproofing projects (e.g., highway sound barriers)

Long-term anti-corrosion requirements in construction and industrial applications

7. How to Choose the Right Perforated Plate?

When selecting between galvanized steel perforated plate and carbon steel perforated plate, consider the following factors:

For humid or highly corrosive environments (e.g., outdoors, coastal areas, chemical plants), galvanized steel perforated plate is recommended for extended durability.

For dry environments with low anti-corrosion requirements, carbon steel perforated plate may be more cost-effective.

For special needs, such as enhanced aesthetics through painting or powder coating, customized surface treatments can be tailored to project requirements.

Conclusion

Galvanized steel perforated plate and carbon steel perforated plate each have their advantages. The choice depends on the specific application scenario. If strong corrosion resistance and long-term durability are required, galvanized steel perforated plate is the better option. For cost control in low-corrosion environments, carbon steel perforated plate is more economical. By selecting the most suitable perforated plate based on actual needs, you can achieve an optimal balance between cost and performance, ensuring project quality and longevity.

If you have any perforated plate requirements, feel free to contact us. We offer a variety of custom specifications to meet your diverse application needs!