Difference Between Perforated Metal Sheets and Expanded Metal Mesh

Source:www.cn-psp.cnAuthor:河北森驰公司 Last updated:2025-03-03 15:56:21 Browse:

Perforated metal sheets and expanded metal mesh are two different types of metal products, each with unique manufacturing processes, structural features, and applications. While both are made from metal, they differ significantly in how they are produced and the purposes they serve. Understanding these differences is crucial for selecting the right material for your needs.

Manufacturing Process

Perforated Metal Sheets

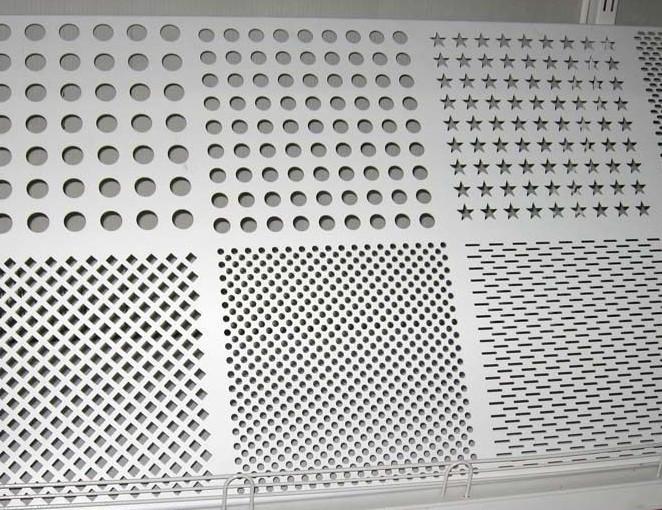

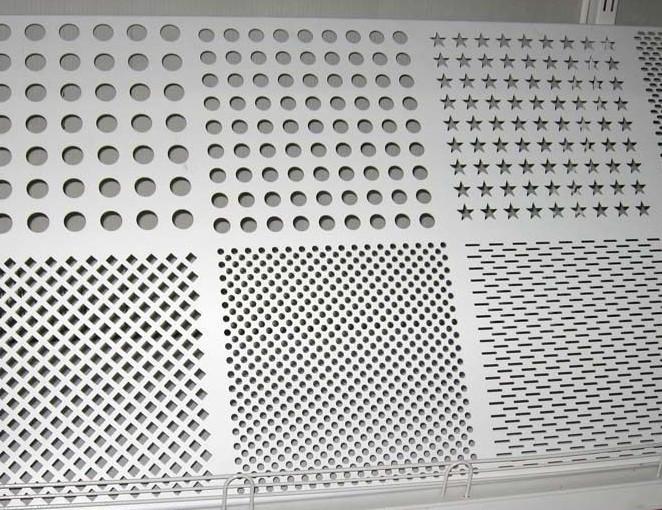

Perforated metal sheets are made by using a CNC punching machine to create specific patterns and spacing of holes in a metal sheet (such as stainless steel, aluminum, steel, etc.). The hole shapes can be round, square, rectangular, oval, star-shaped, triangular, and even custom-designed. The hole diameters typically range from 0.5mm to 200mm, and the thickness of the metal sheets varies from 0.5mm to 20mm.

In addition to punching, perforated metal sheets can undergo further processing such as laser cutting, bending, spraying, powder coating, fluorocarbon spraying, and polishing to meet specific aesthetic and functional requirements.

Expanded Metal Mesh

Expanded metal mesh is produced using a specialized machine that stretches a metal sheet to form a mesh-like structure. Unlike perforated metal sheets, the holes in expanded metal mesh are not fully punched through. Instead, they are formed during the stretching process, usually resulting in diamond or rectangular-shaped openings. This process gives expanded metal mesh greater flexibility and elasticity compared to perforated metal sheets. The hole size in expanded metal mesh is typically larger, and its open structure provides better ventilation and light transmission.

Structure and Characteristics

Perforated Metal Sheets

Perforated metal sheets, with their holes completely punched through the metal, offer higher structural strength and rigidity. This makes them ideal for applications requiring strength and stability, such as in architectural, decorative, and security applications. Perforated sheets are particularly suitable for soundproofing, ventilation, and noise reduction, often used in ceilings, walls, stair railings, and privacy screens.

Expanded Metal Mesh

Expanded metal mesh, due to its unique stretched structure, is generally lighter and has a higher open area. Its mesh design provides excellent tensile strength and impact resistance, making it perfect for applications where large surface areas and strength are required. Expanded metal mesh is often used in protective barriers, fences, and other security applications, and is particularly valued for its ability to provide both strength and flexibility.

Applications

Applications of Perforated Metal Sheets

Perforated metal sheets are used in a wide range of industries, thanks to their aesthetic appeal and functional versatility. Their ability to balance beauty and performance makes them an excellent choice for architectural elements, industrial processes, and more. Common applications include:

1.Architectural Decoration: Used for wall coverings, ceilings, and exterior/interior decoration.

2.Safety Features: Such as security grilles, privacy screens, and stair railings.

3.Soundproofing and Ventilation: Often used in air vent covers, soundproofing panels, and noise-reducing barriers.

4.Filtration: Employed in various industrial processes for filtration and separation of liquids or gases.

Applications of Expanded Metal Mesh

Expanded metal mesh is renowned for its strength, flexibility, and lightweight properties, making it ideal for industrial and protective applications. Its mesh structure provides exceptional impact resistance and adaptability. Typical uses include:

1.Traffic and Road Infrastructure: Used in highway barriers, railway fences, and other traffic safety structures to prevent debris or objects from impacting the road or vehicle.

2.Building Reinforcement: Commonly used in reinforcing structures, providing additional strength to buildings or fencing.

3.Machinery Protection: Often used as protective covers for industrial equipment and machines, guarding against flying debris or sparks.

4.Agriculture and Landscaping: Used in farm fences, garden structures, and other agricultural applications to provide protection and support.

Conclusion

While both perforated metal sheets and expanded metal mesh are made from metal, they differ significantly in their manufacturing processes, structural properties, and areas of application. Perforated metal sheets are known for their high strength, aesthetic versatility, and ability to balance both functionality and design, making them perfect for architectural and decorative uses. On the other hand, expanded metal mesh is designed for applications that require greater tensile strength, flexibility, and a larger open area, making it ideal for protective, filtration, and industrial uses. By understanding the differences between the two materials, you can choose the one that best suits your project's needs, ensuring the optimal balance between performance and cost.