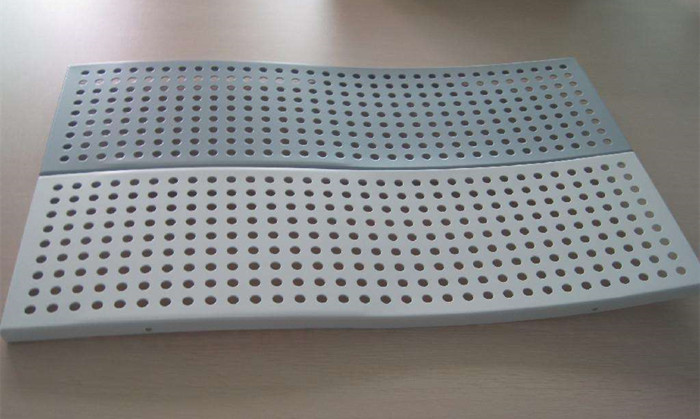

Introduction to Perforated Aluminum Plate Specifications and Models

Source:www.cn-psp.cnAuthor:河北森驰公司 Last updated:2025-03-03 15:57:47 Browse:

Perforated aluminum plate is a type of metal sheet made by using CNC punching machines and custom molds to create precise holes in high-quality aluminum sheets. Due to its excellent physical properties and aesthetic appearance, perforated aluminum plate is widely used in construction, decoration, filtration, ventilation, soundproofing, and other industries. The specifications and dimensions of perforated aluminum plates can be highly customized to meet various project and design requirements.

1. Material Thickness

The thickness of perforated aluminum plates typically ranges from 0.5 mm to 20 mm. The thickness can be customized based on specific application needs:

Thin aluminum plate (0.5mm - 3mm): Suitable for decorative applications such as building facades, interior wall decorations, ceilings, etc. Thinner aluminum plates are lightweight and easier to process, making them ideal for visual effects and aesthetic designs.

Medium-thickness aluminum plate (3mm - 6mm): Widely used in architectural curtain walls, billboards, artistic decorations, and furniture. It offers a good balance of strength and formability.

Thick aluminum plate (6mm - 20mm): Suitable for applications that require higher strength, such as structural components, soundproof panels, ventilation systems, and industrial partitions. Thicker plates offer superior durability and can withstand larger impacts and pressures.

2. Shape and Size

The standard dimensions for perforated aluminum plates are typically widths of 1m, 1.2m, and 1.5m, while the length can be customized according to the customer’s requirements. For specialized applications, the plates can be produced in custom shapes, although custom shapes may incur additional material waste and cost. Common aluminum plate sizes include:

Standard length and width dimensions: 1000mm x 2000mm, 1200mm x 2400mm (customizable to project needs).

Special sizes: Perforated aluminum plates can be customized into larger dimensions or even cut into different shapes such as circles, rectangles, or curved forms.

3. Hole Diameter

The hole diameter of perforated aluminum plates typically ranges from 0.5 mm to 200 mm. The choice of hole diameter not only affects the appearance of the plate but also influences its performance and application:

Hole diameter and plate thickness ratio: Generally, the hole diameter should not be smaller than the material thickness to ensure the structural integrity and strength of the plate. Larger hole diameters are suited for ventilation or filtration purposes, while smaller hole diameters are more appropriate for decorative designs.

Special applications: For applications requiring high airflow or lightweight structures, larger hole diameters can be chosen. Smaller hole diameters may be more suitable for applications with higher noise control, dust prevention, or filtration requirements.

4. Hole Pitch

Hole pitch refers to the center-to-center distance between adjacent holes and can be customized according to customer needs. The hole pitch not only affects the aesthetic appeal but also directly impacts the plate's load-bearing capacity and functionality:

Common hole pitch: The hole pitch is usually required to be at least 1.5 times the plate thickness to ensure sufficient strength and prevent the plate from becoming brittle or unstable due to overly close holes.

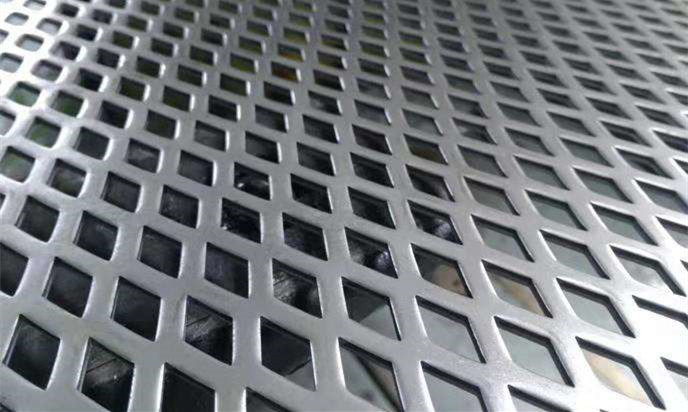

Hole pitch arrangement: Common arrangements include staggered and linear patterns. Staggered patterns help improve overall strength, while linear patterns provide a simpler visual effect.

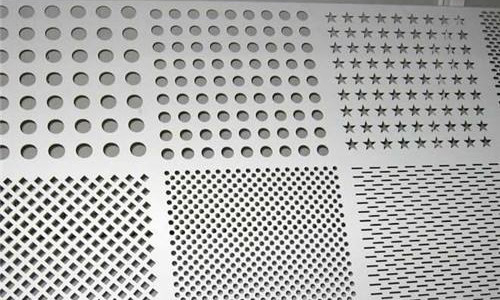

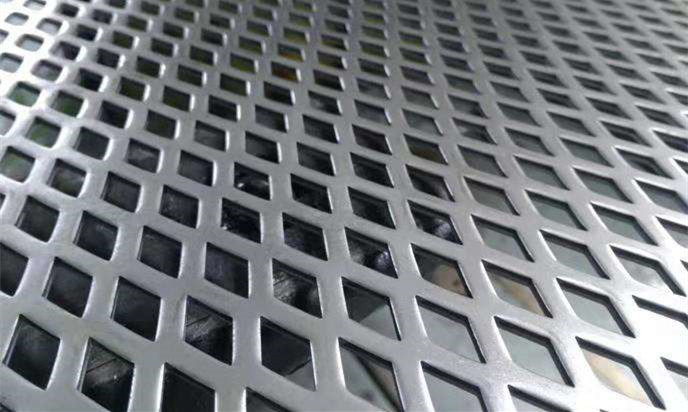

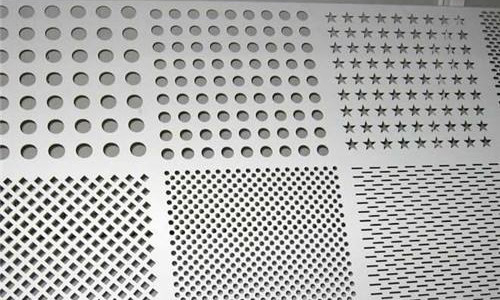

5. Hole Shape

Perforated aluminum plates come in a variety of hole shapes, including round, oval, elongated round, square, rectangular, triangular, pentagonal, hexagonal, octagonal, and more. Different hole shapes not only meet different design aesthetics but also impact the plate's performance and suitability for various applications:

Round holes: The most common hole shape, suitable for ventilation, filtration, and decorative purposes.

Oval holes: Often used in architectural facades, offering good ventilation and aesthetic appeal.

Square/Rectangular holes: Ideal for applications requiring larger open areas, such as air conditioning intake/outlet systems.

Custom hole shapes: Custom shapes such as plum blossom, diamond, fish scale, etc., can be created based on customer design needs, adding decorative or functional value.

6. Customization and Combinations

Perforated aluminum plates are highly customizable materials, and clients can combine the various factors discussed above to create a specification that suits specific applications. For example, for architectural or fire-resistant needs, thicker plates with smaller hole diameters and closer hole spacing may be selected. For ventilation or filtration applications, larger hole diameters and higher hole porosity may be preferred.

7. Applications of Perforated Aluminum Plates

Due to their excellent characteristics, perforated aluminum plates are used in a variety of industries and fields:

Construction: Used in building facades, curtain walls, ceilings, window shading, etc.

Industrial Applications: Used in machine enclosures, ventilation systems, filtration media, soundproof walls, and more.

Decorative Design: Used in interior and exterior decoration, art installations, room dividers, furniture, etc.

Soundproofing and Ventilation: Used in soundproof panels, air conditioning systems, ventilation ducts, and air flow systems.

Automotive and Marine Industries: Used in ventilation systems, exterior decoration, etc.

8. Advantages Summary

Perforated aluminum plates offer significant advantages in both aesthetics and functionality:

Lightweight yet strong: Aluminum has high strength and corrosion resistance, and the perforation design makes the plate lightweight, suitable for a wide range of applications.

Design flexibility: Various hole shapes, diameters, hole pitches, and plate sizes can be customized to meet specific design needs.

Durability: Aluminum has excellent resistance to oxidation, allowing perforated aluminum plates to maintain a long lifespan even in harsh environments.

The versatility and customizability of perforated aluminum plates make them an ideal choice for modern architectural and decorative needs. Whether for aesthetic design or functional purposes, there is always a suitable solution available.