Advantages of our small hole sieve plates:

1. Customized production, accurately meeting customer needs

Compared with standardized products from other distributors, the biggest highlight of our production model is customization. Regardless of the specifications, aperture, or material of the small hole sieve plates you need, we can produce them individually according to design drawings and actual application requirements. Through strict process flows and quality inspections, every batch of products ensures it reaches the parameters required by users, providing stable and reliable screening solutions for customers.

2. Rich product specifications, wide application fields

Our small hole sieve plates cover multiple specifications and models, widely used in mining, chemical, building materials, food processing, and agriculture. Here are some common specifications and models:

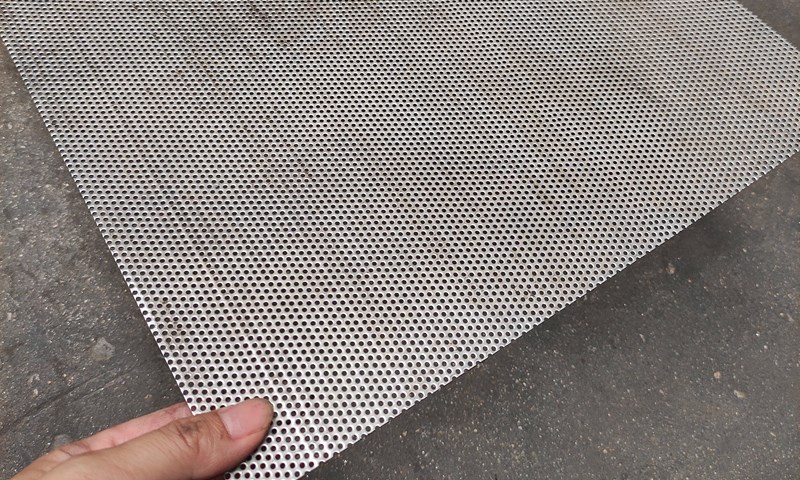

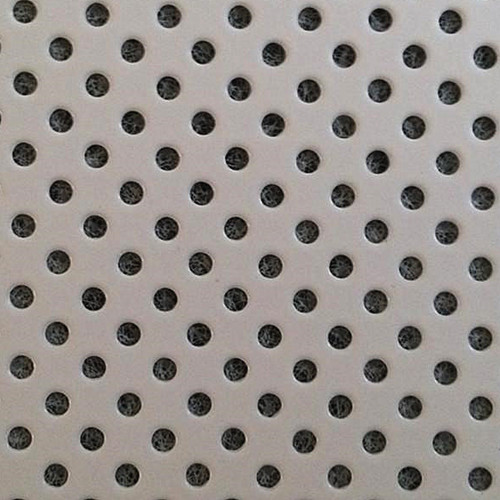

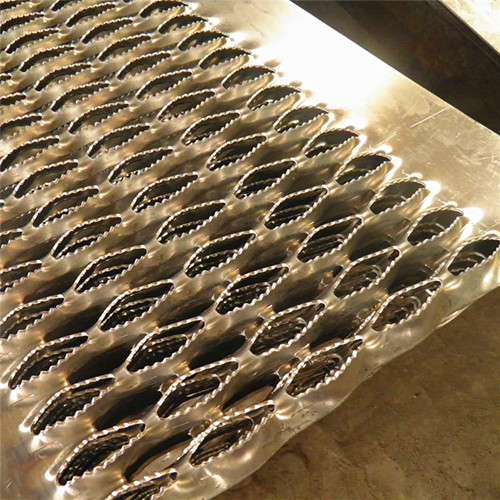

Standard series sieve plates: Suitable for regular screening operations, with uniform apertures and clear hole patterns, suitable for basic screening needs of most industries.

High-precision sieve plates: Using high-precision processing technology, the control of aperture and hole distance is extremely fine, especially suitable for products with smaller particle sizes and high screening accuracy requirements.

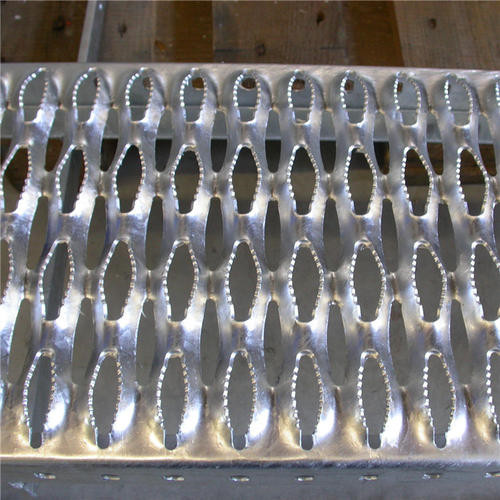

Wear-resistant series sieve plates: Made of highly wear-resistant materials, after special surface treatment, extending service life, suitable for high-wear environments.

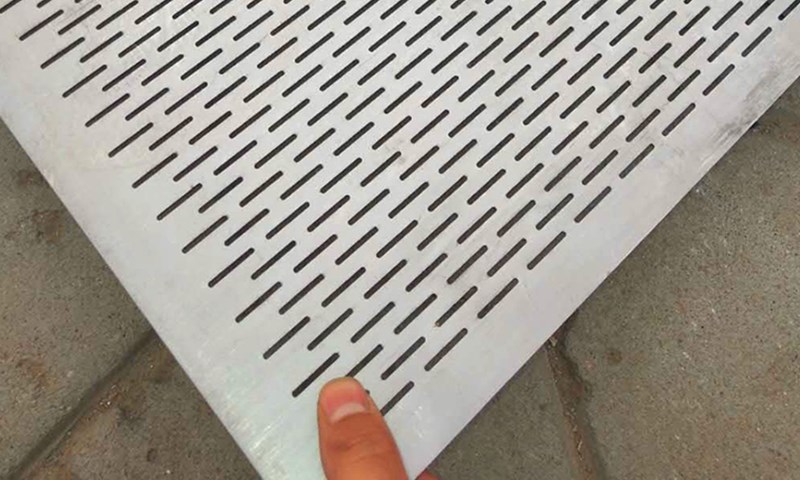

Special custom series: Custom non-standard production according to the special structural requirements of customer equipment, solving special working condition problems that conventional products cannot meet.

By continuously optimizing design and production processes, we ensure that each product not only leads in screening efficiency but also performs excellently in durability and stability.