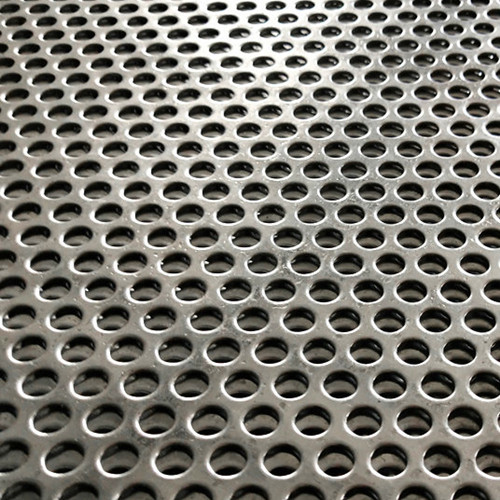

Micropore sieve trays, also known as microporous perforated panels, are metal sheets with small holes created through precision processing. The hole sizes typically range from 0.2mm to 20mm, with uniform holes and no burrs. These sieve trays provide high-efficiency filtration and separation, with a smooth surface, consistent hole spacing, and plate thickness according to customer requirements. Micropore sieve trays are widely used across various industries that require fine filtration and separation.

Micropore sieve trays find applications in many fields, including the chemical, pharmaceutical, food and beverage, tobacco, paper, and more specialized industries. Common applications include chemical machinery, pharmaceutical equipment, food and beverage machinery, tobacco machinery, air conditioning and noise reduction equipment, dry cleaning machines, electronic devices, arts and crafts production, paper making, hydraulic parts, filtration systems, and more.

We also offer customized production services based on customer requirements, ensuring the product's size, material, thickness, and hole type meet specific application needs.

Micropore Sieve Tray Specifications and Customization Options

We offer a wide range of specifications and models for micropore sieve trays. Customers can customize various parameters based on their actual needs, including plate size, material, thickness, hole type, and more. The following are the details:

Plate Size: Standard sizes typically include 1m × 2m, 1.2m × 2.4m, etc. Additionally, we offer customized processing for different widths and lengths based on customer requirements.

Plate Thickness: The thickness of micropore sieve trays can be customized, ranging from 0.15mm to 3mm, depending on filtration needs and pressure tolerance.

Plate Material: We provide several material options for micropore sieve trays to suit different environments:

Cold-rolled Steel: Offers good flatness, suitable for general filtration needs.

Hot-rolled Steel: Suitable for environments that require higher pressure and temperature resistance.

Galvanized Steel: Provides strong corrosion resistance, ideal for humid or corrosive environments.

Manganese Steel: Offers high wear resistance, suitable for applications with high impact or friction.

Aluminum: Lightweight and corrosion-resistant, ideal for light industries and food processing.

Stainless Steel: Corrosion-resistant, high-temperature resistant, commonly used in chemical, pharmaceutical, and food industries.

Color Steel: Used for applications that require good appearance and corrosion resistance.

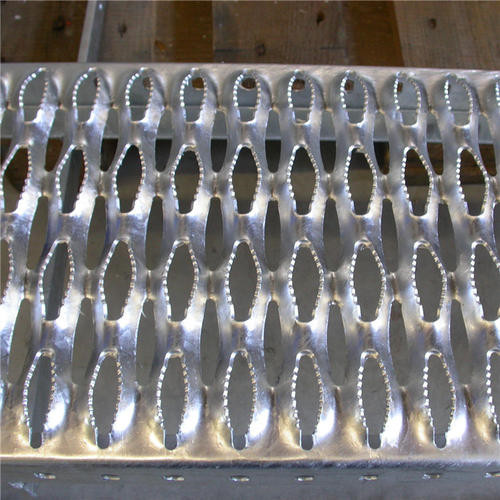

Hole Type: The standard hole type is round holes, but we can also customize special hole types such as square, elongated, or slotted holes, depending on customer needs.

Hole Size: The hole size for micropore sieve trays can be customized between 0.2mm and 20mm to meet different filtration and separation requirements.

Surface Treatment: To enhance the durability and aesthetics of the micropore sieve tray, we offer a variety of surface treatments:

Spray Coating: Suitable for cold-rolled and galvanized plates, providing an aesthetic appearance and improved corrosion resistance.

Fluorocarbon Coating: Suitable for high-temperature and highly corrosive applications, offering superior protection.

Electrostatic Powder Coating: Used to enhance corrosion resistance, typically for electronic and high-tech applications.

Electropolishing: Applied to stainless steel trays to improve surface smoothness and corrosion resistance, suitable for high-end applications.

Anodizing: Primarily used for aluminum plates to enhance surface hardness and wear resistance.

Applications of Micropore Sieve Trays

Micropore sieve trays, with their excellent filtration capabilities, are widely used in various industries and applications, including the following:

Chemical Industry: Micropore sieve trays are extensively used in chemical equipment, especially in distillation, adsorption, and separation processes, to efficiently filter out solid impurities and ensure efficient chemical reactions.

Pharmaceutical Industry: In pharmaceutical production, micropore sieve trays are used to filter out impurities in medicinal liquids, ensuring product purity and quality.

Food & Beverage Industry: In food processing machinery, micropore sieve trays help remove impurities, ensuring food safety and hygiene.

Tobacco Industry: Micropore sieve trays are used in tobacco filters and tobacco screening processes to ensure product quality.

Air Conditioning and Noise Reduction Equipment: Micropore sieve trays are used in air conditioning, cooling systems, and noise reduction equipment to filter out airborne impurities and reduce noise levels.

Environmental Protection and Water Treatment: Micropore sieve trays are also widely used in water treatment and wastewater purification, efficiently removing solid particles from water.

Papermaking Industry: In papermaking, micropore sieve trays are used to filter out impurities from pulp, ensuring the quality of the paper.

Hydraulic Systems: Micropore sieve trays are applied in hydraulic systems to clean liquids and protect machinery from damage.

Micropore Sieve Tray Pricing

The price of micropore sieve trays varies depending on the specifications and models, such as size, material, hole type, and surface treatment. Since each customer’s requirements are unique, we provide personalized pricing services. If you would like to receive a detailed quote, please contact us via email or phone, providing the specifications and model you require. We will offer a competitive price based on your specific needs.

Why Choose Us?

Customized Services: We offer fully customized micropore sieve trays, adjusting the product’s size, material, thickness, and other parameters according to customer needs to ensure the best solution for your application.

High-Quality Assurance: We use high-quality raw materials and strictly control the production process to ensure each micropore sieve tray meets the highest standards of accuracy, durability, and performance.

Global Supply: Our products are exported to numerous countries and regions worldwide, serving customers across various industries. We are committed to providing high-quality products and services to global partners.

Fast Delivery: With a well-organized production process and inventory management, we can quickly respond to customer orders, ensuring timely delivery.