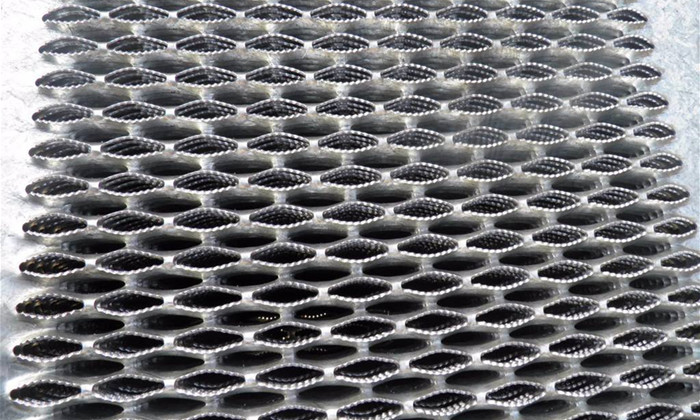

Crocodile mouth safety grating is a type of anti-slip plate, manufacturers use high-quality low-carbon steel plate or stainless steel plate to punch serrated holes. They use shearing to cut the required size and bend it. There is one bending or two bending after forming the products that customers need. After hot-dip galvanizing anti-rust treatment, it has a long service life and is beautiful and sturdy. However, it will deform during production. What causes this and how to solve it?

The causes and solutions for the deformation of Crocodile mouth safety grating production are as follows:

First, when processing Crocodile mouth safety grating, the area of the perforated plate is large, and the large-area perforation causes the perforated net to deform due to heat generated by perforation. The solution is to perforate the Crocodile mouth safety grating (whatever type of hole) with a small perforated area. If it is too large, inform the customer of the consequences in advance, and whether it can be perforated.

Second, the punching mold for crocodile teeth hole type is too rough or not polished, and resistance is generated during production punching, which is easy to scrape the plate, causing the perforated net plate to deform. The solution is to polish the punching mold well, and the smooth mold reduces resistance and punching without deformation.

Third, no lubricant is sprayed during production, and the rough plate surface is easy to damage the mold and cause the plate surface to deform. The solution is to spray some lubricant on the plate during perforation, and the smooth plate surface will be easier to perforate, and no deformation will occur.

2024-12-10

2024-09-17

2024-11-01

2024-10-31

2024-11-29

2024-12-03

2024-12-03

2024-10-05

2024-11-29

2024-10-23